Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

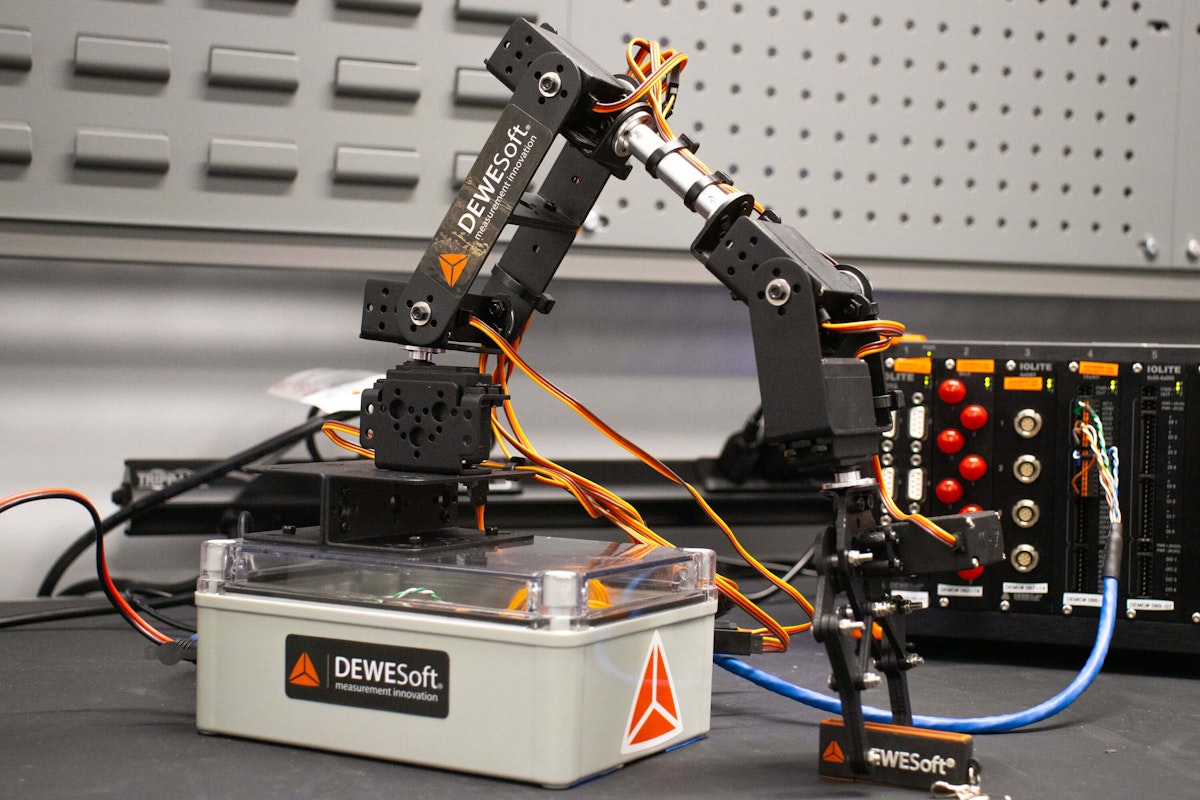

Optimizing Servo Control Systems with Dewesoft Hardware and Software

August 28, 2025

Test labs worldwide rely on a variety of devices to test their products. These systems ensure product performance, from linear actuators that move test articles to programmable logic controllers (PLCs) that provide precise, high-speed control. However, many controllers have awkward user interfaces and require specialized programming knowledge. Furthermore, they often lack synchronized high-speed data acquisition capabilities.

The solution? Dewesoft data acquisition (DAQ) hardware combined with the award-winning DewesoftX software offers a powerful and intuitive platform for controlling servo drivers while ensuring seamless data collection.

System configuration of the robotic arm

The proof-of-concept system included:

Robotic arm with servo motors

IOLITE R8 DAQ system

Arduino microcontroller installed in a project box.

This setup illustrates how Dewesoft hardware seamlessly integrates with servo control systems in a compact, practical environment.

Proof of concept: robotic arm demonstration

We developed a proof-of-concept robotic arm driven by geared servo motors similar to those used in remote-controlled planes to demonstrate this capability. These motors operate via high-speed PWM (pulse width modulation) signals and are controlled by an Arduino microcontroller programmed as a servo controller.

By integrating Dewesoft IOLITE R8 hardware equipped with a 16xAO analog output card, we provided precise ±10 VDC control signals to the servo motors. With 16-bit resolution, this setup achieved 13,000 discrete output points at ±5 VDC for exceptional accuracy. The SIRIUS analog out module with 24-bit resolution is available if more resolution is needed.

The Dewesoft IOLITE R8 hardware also features digital outputs capable of switching loads up to 50 V at ≤ 0.5 A, expanding its versatility.

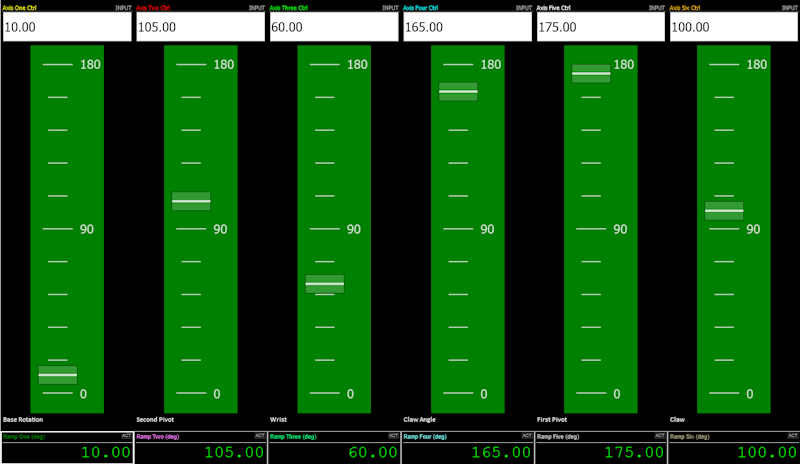

Software configuration with DewesoftX

User-friendly and powerful, DewesoftX data acquisition software combines robust data acquisition capabilities with extensive control output functions. Built-in modules provide tools for everything from simple formulas and statistics to advanced fatigue analysis and diagnostics.

DewesoftX’s built-in formula editor was used to define control logic for the robotic arm demonstration. These formulas controlled arm movement, specifying desired positions, speed, and stop conditions. Configurable user inputs allowed operators to adjust movement parameters via visual interface widgets such as buttons, switches, and sliders.

A crisp, modern user interface for enhanced control

Many servo controllers have outdated, unintuitive interfaces. DewesoftX overcomes this with a modern and flexible display system. Widgets such as chart recorders, scopes, gauges, digital and analog meters, and FFT plots provide engineers with comprehensive visualization tools.

Interactive controls like buttons, switches, and rotary dials simplify the user experience. DewesoftX's support for touchscreen interfaces makes system control faster and more intuitive. These widgets can be freely sized, positioned on one or more screens, and assigned to any channel or function.

An assortment of user inputs provides configurable inputs for operators to specify a desired position, the speed at which the arm moves, and to start and stop the test. These user inputs can be used within formulas as triggers to start and stop storing, perform various actions within DewesoftX, and directly control the output channels. The inputs are tied to one of many different display widgets on DewesoftX’s Measure screen. They allow the user to interact with them quickly and graphically.

Automation and sequencing with DewesoftX

Dewesoft’s powerful built-in Sequencer allows engineers to automate tests, improving repeatability and efficiency. Using a ladder logic-style interface, engineers can create automated steps to initiate data acquisition, control outputs, perform analysis, export data to other formats, and even manage setpoints for servo systems.

In the robotic arm demonstration, the Sequencer moved the arm to designated positions, held each position for a set duration, and then automatically proceeded to the next position. This ensures consistent testing conditions with minimal manual intervention.

A short demonstration of the proof-of-concept test system.

Advanced DAQ instruments for servo control

Dewesoft offers a wide range of DAQ hardware solutions to meet various testing needs:

SIRIUS XHS DAQ provides ultra high-speed DAQ with sampling up to 15 MS/s.

SIRIUS DualCore DAQ provides 200 kHz sampling and 160 dB dynamic range.

IOLITE DAQ delivers high channel density for combined data acquisition and real-time control systems.

KRYPTON DAQ modules offer rugged, IP67-rated analog and digital recording in harsh, all-weather operating environments.

OBSIDIAN Data Logging systems are based on an embedded processor for long-term, unattended operation. They also combine real-time data and control capabilities.

All Dewesoft instruments are designed for seamless synchronization, ensuring accurate data correlation across multiple systems. They are part of a synchronized ecosystem whose elements can be combined in countless ways. This flexibility makes Dewesoft solutions ideal for testing applications requiring high-speed data collection and precise control outputs.

Communication protocols for flexible integration

DewesoftX supports numerous communication protocols, enabling integration with a wide variety of devices and controllers. Supported protocols include:

Modbus TCP

OPC UA

CAN bus

Serial Communication

These plugins have been used to integrate Dewesoft with various third-party systems, including these:

Mensor Controller Automation manual

Scanivalve Plugin manual

Dewesoft plugins enable connectivity with specialized devices like thermal cameras and Scanivalve pressure readers, expanding its versatility. Dewesoft’s dual EtherCAT busses allow the system to interface with DewesoftX for data acquisition and third-party EtherCAT masters for real-time control.

This case study describes the following capabilities:

Real-world applications with Dewesoft solutions

Dewesoft hardware and software have been successfully implemented in various applications, including:

Conclusion

Dewesoft’s hardware and software solutions provide a powerful, flexible, and user-friendly approach to optimizing servo control systems. By integrating high-speed data acquisition with real-time control capabilities, Dewesoft products eliminate the complexities of traditional controllers while enhancing precision and efficiency.

The proof-of-concept robotic arm demonstration highlights the seamless interaction between Dewesoft’s IOLITE R8 hardware, Arduino microcontrollers, and DewesoftX software, showcasing precise motion control, advanced visualization tools, and automation through the built-in Sequencer.

Dewesoft’s extensive support for communication protocols enables seamless integration with third-party systems, making it a versatile choice for a wide range of industrial and research applications. With its innovative approach to servo control, Dewesoft continues to set new standards for efficiency, usability, and data integrity in testing and automation environments.