Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Train Brake Performance Testing in Winter Conditions

Carsten Frederiksen && Magnus Skärhem (business unit manager and head of AFRY Test Center)

AFRY Test Center

February 3, 2023

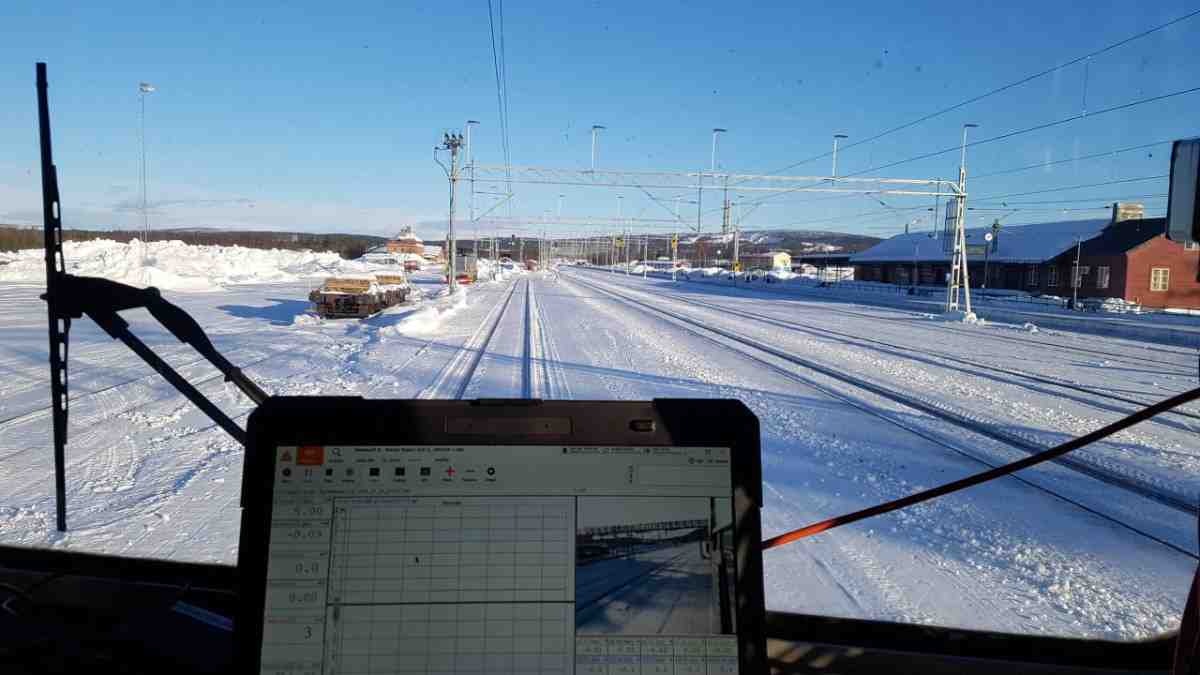

On behalf of the Swedish train transportation client, AFRY Test Center in Sweden has carried out train set brake performance testing in the northern part of Sweden.

In early 2020 a train set with freight wagons was equipped with various types of brake blocks (brake components) to compare their brake performance in winter conditions. Also, some reference tests with disc brakes on freight wagons were performed.

Measuring strain and temperature was done using robust distributed Dewesoft KRYPTON DAQ units and easy-to-use DewesoftX software delivered the results we needed.

Introduction

In 2019, the AFRY test Center was hired by the Swedish train transportation client to assist with measurement technology expertise with the aim of mapping the braking effect on freight trains when driving in different winter conditions.

The AFRY Test Center has been around for more than 30 years and is one of the largest independent test labs in Sweden. The AFRY test Center performs test assignments in its own well-equipped test lab located in Borlänge in Sweden. Measurement assignments are performed as field tests in different places both inside and outside Sweden and in the lab environment in connection with various tests.

The test center is part of AFRY, international engineering, design, and advisory company having 17,000 devoted experts operating in more than 40 countries across the world. AFRY is organized into five divisions, Infrastructure, Industrial & Digital Solutions, Process Industries, Energy and Management Consulting, which offer services across three main sectors: infrastructure, industry, and energy.

The Test Center is a business unit belonging to the division Industrial & Digital Solutions and its operations are focused on testing and verification. The business mainly consists of three areas, namely measurement, testing and analysis, and simulation.

Our customers are found in all types of industries and the assignments range from, for example, verification of implants to ships to process plants and vehicles of all kinds. As the assignments are very different, it is important that the equipment at the AFRY Test Center is easy to use, flexible and durable therefore the center has used Dewesoft hardware and software for many years.

EU regulations on rail noise

The background of this brake test assignment is that noise is an important public health issue and can have negative impacts on human health and well-being. Noise from freight wagons, especially wagons equipped with cast iron brake blocks, contributes the most to railway noise.

To address rail noise levels in Europe the European Union has recommended changes to the European Commission Regulation (EU) No 1304/20142 (TSI Noise) to make current maximum noise levels for new freight wagons applicable to already existing freight wagons. The proposed amendments would mean retrofitting cast-iron brake blocks with “silent breaks” (composite brake blocks or disc-brakes); composite brake blocks being the cheaper alternative.

The customer has looked at the impact of the proposed changes to the Swedish rail network. The changes will have an effect on noise reduction but will lead to a financial burden to wagon keepers and railway undertakings operating the wagons.

Tests have shown that composite brake blocks lose braking performance in severe winter conditions. Operational measures can partly mitigate this loss. When trains arrive in Sweden, from Europe, railway companies will also need to add wagons equipped with cast iron brake blocks to the trains containing wagons equipped with composite brake blocks to ensure an acceptable level of braking performance. Despite these measures, the speed will have to be reduced to a maximum of 80 km/h which will lead to a reduction in capacity on an already saturated network.

This assignment posed several challenges to the AFRY Test Center. The challenges that were most important to solve were the environmental challenges with severe cold with ice and snow but also moisture in zero-degree weather. In addition, the length of the train configuration required signal transmission over relatively long distances and the possibility of distributing different parts of the measuring system in different carriages. The assignment also required that the train's position, speed, and current weather conditions be documented during each test case.

In order to be able to carry out the desired tests and measurements a measurement system was required that had:

very good environmental resistance and

possible to have distributed DAQs to different locations in the train set.

The harsh outdoor environment also posed challenges to our test staff and it was therefore important that the system was easy to use and install in these conditions.

At AFRY Test Center we have already used equipment from Dewesoft for many years. It was natural for us to investigate whether Dewesoft in Sweden could offer a suitable measuring system for this assignment. As the test staff was already familiar with and used to working with Dewesoft equipment, this was an aspect that was considered in this choice of supplier.

Measurement setup

Dewesoft Sweden was contacted to offer a measurement solution that was flexible and that could withstand the rough environment of the Scandinavian winter climate with low temperature, snow, ice, vibration, etc.

Another challenge of this measurement setup was that the train would go in both directions, from north to south, and vice versa. The test engineer should require minimum work and should only have to grab the measurement laptop to the other locomotive. In other words, the measurement chain needed to work from both directions without any adjustments to the setup.

The final solution was a number of KRYPTON units daisy-chained together to measure strain and temperature. 2x KRYPTON-8xTH and 12x KRYPTON-6xSTG data acquisition modules with power injectors and power junctions were used. Also, a GPS receiver from Dewesoft was used to get the positioning of the train.

The complete setup was tested and simulated by the Dewesoft R&D department in Slovenia to make sure it would work as required by AFRY.

KRYPTON is a rugged and distributed EtherCAT data acquisition system for field measurement in extreme and harsh environments. Krypton DAQ systems offer IP67 degree of protection and can operate in the extreme temperature range from -40 to +85°C and offer high shock protection.

Krypton DAQ units are connected with a single cable for data, power, and synchronization. They can be distributed over a large area with distances up to 100 meters between DAQ nodes.

All KRYPTON units come with DewesoftX data acquisition software included – and with free lifetime upgrades. The software is easy to use, yet very robust in functionality.

Conclusion

The delivery time was crucial for this project as AFRY had a tight deadline so close collaboration between AFRY and Dewesoft was of high importance. Dewesoft supported AFRY to specify what they needed and how the measurement setup should be configured.

Dewesoft provided a robust DAQ solution that could:

Withstand the harsh climate and

Could work just as well from both ends of the train the setup without any re-configuring of the setup due to Dewesoft EtherCAT technology that is used for the KRYPTON product line.

This feature meant that there was no delay in train departures due to technical issues or adjustments of the setup each time the train switched direction or locomotive. And in the end much less stress for the test engineer.

The user interface in the software is friendly and it makes it extremely easy to use the software. The Dewesoft DAQ hardware was simple and fast to install and could still withstand the harsh conditions of the Swedish environment. The KRYPTON DAQ modules were purchased for this specific test assignment but will be used for other projects as KRYPTON DAQ modules are compatible with other Dewesoft DAQs.

As this is not an everyday measurement, it is crucial to understand the setup and challenges the customer is facing. We were very happy with the end result, the stability of the system, and the support that was provided to their test engineers. And who knows, AFRY will do more measurements and might need to expand their setup.