Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

What Is a Data Logger (Datalogger) - The Ultimate Guide

September 29, 2025

In this article we will learn about data loggers, describing them in enough detail that you will:

See what a data logger really is

Learn about the key data logger features and capabilities

Understand how they differ from data acquisition (DAQ) systems

Are you ready to get started? Let’s go!

What is a data logger?

A data logger (also known as a datalogger or data recorder) is a small and relatively inexpensive electronic device that monitors and records data over time (such as voltage, temperature, or current) via an internal or external sensor. It is usually based on a digital processor.

The data logger is chosen instead of a data acquisition system when the application does not require high-speed recording, but it does require extended recording times. They are less expensive than DAQ systems.

Data loggers are the “workhorse” of recording instruments. They can record data for days, weeks, or even years at a time. This process is commonly referred to as data logging.

Data loggers can be defined by looking at these basic characteristics:

Sample Rate

Input Types

Channel Count

Data Storage

Recording Times

User Interface

Local Monitoring

Power System

Cost

Types of dataloggers

Major types of dataloggers based on the signal type they record:

Temperature data loggers

Voltage data loggers

Current data loggers

Power data loggers

Electrical data loggers

Vibration data loggers

Shock data loggers

Strain gauge data loggers

Mixed signal data loggers

GPS logger

Data logger sampling rate

Data loggers are made for largely slow signals, i.e., conditions that change slowly over a long period of time. Some are made to monitor for glitches and short circuits, which may not occur for days, weeks, or months. Any physical or electrical property that can be converted to an electrical signal can be recorded by a data logger, within its bandwidth, of course.

Common data logger sample rates are 1 S/s up to 100 S/s per channel. This is quite slow compared to modern digital DAQ systems. Low sample rates are the reason they can record for such long periods of time.

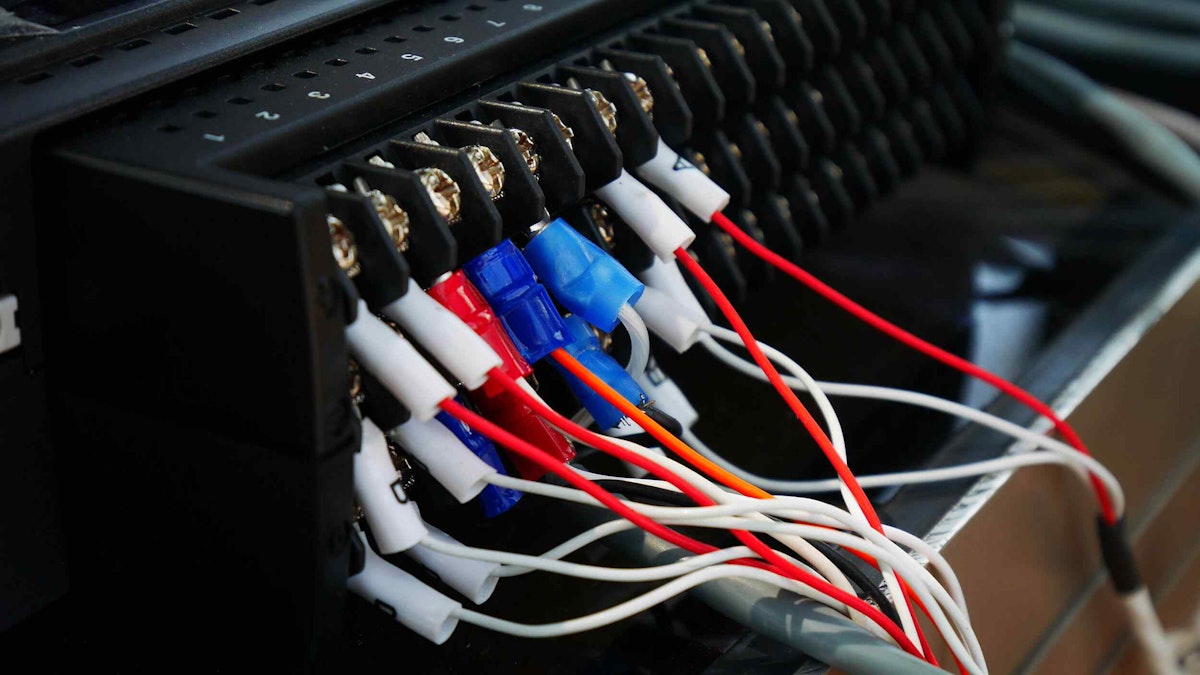

The sensor inputs built into data loggers are, with a few exceptions, limited to voltage, 4-20 mA current, temperature, humidity, and pulse signals. They often use screw terminal-type connectors because they are left in place for months or years at a time, and the signal connections, therefore, do not change very often.

4-20 mA current loop outputs are common among a wide variety of industrial sensors, including those that monitor water level, humidity, temperature, pressure, weather station sensors, door open/closed positions, and hundreds more.

Learn more about sensors:

Channel count

Data loggers provide anywhere from a single channel to 32 input channels, although four to eight-channel models are the most common. A few models offer more, up to 100 channels or more. Relatively few data logger applications require a large channel count, although they do exist. Multiple data loggers can be used to address very large channel count applications.

Check out Dewesoft's modern, digital data acquisition systems which offer DAQ system configurations from 1 .. 1000's of channels.

Low channel count data loggers

One example of a low channel count data logger is the GL240 from Graphtec Corporation. It features ten multi-function analog input channels, where each one can be configured for voltage, current, or temperature.

The GL240 has a built-in display and a simple user interface much like a TV remote control. It can acquire data from internal RAM or flash memory. Collected data can be transferred to a host computer via ethernet, USB, or an optional WIFI interface. It can record up to 10 samples/second when all ten channels are being recorded.

High channel count data loggers

One example of a high channel count data logger is the 2680 Series from Fluke Corporation. Each chassis can be expanded from 20 to 120 channels, and multiple systems can be connected together via TCP/IP on ethernet.

This is a high-end data logger, with extremely high galvanic isolation and other capabilities well beyond the typical logger, so the cost is appropriately higher as well.

Like most models, it is a stand-alone data logger, but it can also be connected to a host computer for additional functionality.

Data storage

Data loggers normally store recorded data in their internal non-volatile memory, which is later downloaded to an external computer for analysis. This memory is often measured in kilobytes or megabytes (some data loggers do allow USB flash media to be used, which means that GB storage is possible in those systems). This is because of the low sample rates of data loggers: even if you’re recording 100 channels at 1 S/s with 16-bit resolution (requires 2 bytes per sample), that’s only

After recording, data can be offloaded to external systems for long-term storage and analysis.

Because of their low sample rates, data loggers range from recording times measured in days, to those which can be measured in weeks or months.

Some data loggers offer hard-wired interfaces such as USB or Ethernet for streaming their data out to an external system for monitoring. An increasing number of them offer WIFI streaming

Dewesoft's OBSIDIAN data loggers offer built-in SSD data logging capabilities that allow them to store, visualize, and analyze Gigabytes of recorder data.

User interface

Data loggers normally provide either no interface at all or a basic numerical display. Some models, like the GL240 shown above, provide a relatively sophisticated display incorporating waveforms and numbers.

Because they are sitting there recording for weeks or months at a time, no one is going to be standing there looking at them as they would do with a short, high-speed test using a modern DAQ system.

Some data loggers are equipped with a web or HTTP interface, so connecting to them via ethernet and calling up their IP address in a web browser will allow the user to monitor their values in quasi-real-time.

Most loggers offer drivers for programming environments such as DASYLab® and LabVIEW® - software programming suites offered by National Instruments, to name one. Using these tools engineers can create their own software interface to the data logger hardware. Some DAQ companies provide similar drivers for these programming tools, although they are more likely to include their own turn-key software applications.

Real-time monitoring

Some loggers provide real-time monitoring capability in the form of a built-in LCD display that shows the numerical values being measured in real-time. Others may provide a wired or WIFI interface whereby another computer may access the data in real time. If a data logger does not provide this, it is often necessary to wait until the test is stopped before the data can be accessed via an external computer.

After testing, data is typically offloaded to an external computer for analysis. Some loggers allow real-time monitoring via wired or wireless connection.

Power system

The typical small data logger is a battery-powered, low-power electronic device. Because of their low power draw, many of them can operate for hours without any external power. However, those which must record for extended periods of time require an external power source. The power supplies of small loggers usually have a DC power input, while larger benchtop models have an AC power input.

Data logger pricing and cost

A low-end data logger may cost as little as $100 USD. Mid-range data loggers vary in price from $500 to $3000 USD.

Bus-specific data loggers

Data loggers have generally avoided industry-standard instrumentation protocols like MODBUS and CAN BUS. However, this has been changing, and the adoption of these interfaces is slowly increasing.

Modbus is a royalty-free communications protocol originally invented by Schneider Electric. It is heavily used in supervisory control and data acquisition (SCADA) systems and with programmable logic controllers (PLCs) in industrial applications. Its physical layer is RS485, which is easy to implement and maintain. This protocol is now managed by the Modbus Organization.

The Controller Area Network - better known as the CAN bus was originally developed as a messaging protocol to allow microcontrollers (such as the ECUs) within automobiles to communicate with each other without the need for a centralized computer. It was originally developed by Robert Bosch GmbH, a German automotive systems supplier.

But today, because of its standardization by ISO and broad acceptance across this major worldwide industry, it is used in a wide range of applications, including aerospace, general automation, robotics, and even in the medical industry for controlling prosthetic limbs.

DAQ systems are increasingly able to interface with CAN, both reading data from the sensors on the bus, as well as writing data back out to CAN. DAQ systems from Dewesoft are a great example since their entire product line is CAN compliant.

Dewesoft offers high-speed CAN and CAN FD bus data acquisition systems that can record from 2, 4 or even 8 CAN bus systems simultaneously.

Each of the CAN port on these Dewesoft models is isolated and utilizes high-speed CAN 2.0b standard. It should be noted that in addition to these dedicated CAN modules, CAN interfaces can be added to virtually every Dewesoft DAQ system.

Learn more:

Data loggers are starting to embrace the CAN bus as well. One such entry-level CAN bus data logger is the DS-CAN2 from Dewesoft.

This small logger can record CAN bus data for long durations. CAN bus monitoring can be done for legal, vehicle diagnostics, research, or maintenance purposes.

The use of these standard busses is a positive step in applications where these protocols are already in place, as it allows the data logger to be integrated quite easily.

GPS and GNSS dataloggers

With the development of GNSS satellite positioning systems, dataloggers have also embraced the possibility to log positioning data such as longitude, latitude, and altitude.

These dataloggers simply embed a GNSS-compatible receiver and can log the position of the object on Earth very accurately. In addition to standard GNSS/GPS loggers, we also have Inertial Navigation Systems (INS) and Inertial Measurement Units (IMU) that can also log additional parameters such as orientation, position, velocities, and accelerations.

Common data logger applications

Temperature monitoring and humidity levels in manufacturing environments, storage facilities, hospitals, and other public facilities

Monitor food temperature at all stages of processing and transportation

Monitor HVAC conditions in industrial and commercial facilities

Monitor manufacturing processes of all kinds

Monitor growing conditions in greenhouses and on farms

Monitor the environmental conditions for pharmaceuticals during manufacturing and storage

Monitoring seismic activities in the heavy seismic active areas.

Where are data loggers required

Sometimes data loggers are required by industry and/or government regulations. For example:

EC Directive 92/1, as well as FDA regulations in the USA, dictate that throughout its preparation, storage, and transportation, food must be monitored to ensure that temperatures were maintained at the required levels. This is the ideal application for data loggers that can record the temperature at regular intervals over a very long period of time.

Vaccines and other medicines must be kept within stringent temperatures during manufacturing, packaging, storage, and transportation.

HVAC systems in hospitals and other public places must be constantly monitored to ensure the safety and comfort of people using them. These include not just temperature and humidity but CO2 (carbon dioxide) level detection, ventilation, and more.

The EU, the USA, and other countries have various requirements related to energy efficiency and consumption. Constant monitoring is the only way to ensure and prove compliance.

Summary

If you’re making long-term measurements of voltage, current, temperature, and related sensors that extend over days, weeks, and months, data loggers are ideal measuring instruments. They are typically low-cost and readily available from a range of capable manufacturers.