SIRIUS® Modular

Modular Data Acquisition (DAQ) System

The modal test and modal analysis are indispensable tools to determine natural frequencies, damping ratios, and mode shapes of any structure. With Dewesoft’s modal test solution, you can excite a structure with an impact hammer or multiple modal shakers and easily measure the responses. SISO, SIMO, MISO, and MIMO test configurations are supported. You can import or draw geometry and perform rich visualization and animations. The modal analysis extension provides the tools to estimate modal parameters.

Dewesoft is an out-of-the-box modal solution for Experimental Modal Testing (EMA), Operational Deflection Shapes (ODS), and Operational Modal Analysis (OMA). The system also comes with lifetime FREE software updates and support.

Use the same software to excite the structure using an impact hammer, single or multiple shakers, or obtain deflection shapes using ODS to perform operating machine condition troubleshooting.

DewesoftX software is made for test engineers. Perform a modal test by roving excitation or response points, or controlling the shaker within a single screen. The software detects the measured frequency response functions.

Dewesoft supports a wide range of modal testing methods, including single-reference shaker tests, as well as single-reference roving hammer or roving accelerometer setups. Multi-reference shaker and roving hammer tests are also fully supported, offering flexibility for both simple and advanced structural testing scenarios.

Allows grouping, rejecting, and repeating measurement points (multiple references and excitation points are supported). The ability to move excitation and response points gives the user full flexibility when performing measurements.

In combination with the built-in function generator, the Dewesoft system offers burst, sine sweep, and random noise excitation modes. The user can also excite the structure with externally driven shakers.

An LSCF estimation algorithm with a stability diagram indicates modes at stable poles. CMIF function, an AutoMAC procedure for mode correlation, and synthesized FRF calculation.

Use recorded time data to estimate modal models. With OMA the dynamics of the structural vibrations can be determined directly from the sensor input data via the Dewesoft ARTeMIS OMA software.

The 3D geometry of the structure is animated in all three directions during measurement. Unmeasured points are interpolated for smooth animations. The color of the points changes for easier identification of excitation and reaction points.

Structure geometry can be either drawn directly in the software with a built-in geometry editor or imported via the UNV file. Geometry can also be exported to UNV files for use in external software.

Offline calculations are possible using stored raw time data from all the response and excitation sensors.

All data, from the raw time domain to FRFs, can be exported to various different formats, including standard UNV file format.

Due to its unique architecture, Dewesoft lets you use a virtually unlimited number of input channels offering the option to acquire and analyze data from many sensors at once.

Enjoy our industry-leading 7-year warranty. Our data acquisition systems are made in Europe, utilizing only the highest build quality standards. We offer free and customer-focused technical support. Your investment into the Dewesoft solutions is protected for years ahead.

Connect additional analog sensors (strain gauge, force, temperature, CAN bus, GPS, and countless other data sources) and measure additional parameters simultaneously, with all data perfectly synchronized.

Every Dewesoft data acquisition system is bundled with award-winning DewesoftX data acquisition software. The software is easy to use but very rich and deep in functionality. All software updates are free forever with no hidden licensing or yearly maintenance fees.

And we're confident you'll love it too! But don't just take our word for it. Get hands-on with a demo unit, completely free of charge. No strings attached, just real data. Reach out to your local Dewesoft team and get your demo unit now!

It includes everything you need for advanced data acquisition and common signal processing — no maintenance fees, no contracts. You buy it, you own it. All future updates? Free forever. And the best part? Analysis seats are unlimited and free. Once the data is recorded, anyone can download our software to review and analyze your data — no license needed.

Dewesoft is 100% owned by employees who believe in what we do — and love doing it. We’re in this with heart, passion, and long-term commitment. What does that mean for you? Our core value — caring for our customers — isn’t going anywhere. We’re here for the next 100 years, protected from outside acquisitions. Your investment in our technology is safe, supported, and future-proof.

At Dewesoft, quality isn't just a promise — it's a core value. Our products are 100% designed, developed, and manufactured in-house, right in the heart of the European Union. From precision machining and PCB manufacturing to final assembly and software development — we do it all ourselves, to the highest ISO standards. We're proud to support local production and take social responsibility seriously.

At Dewesoft, quality is more than just a word — it's a commitment. That's why our products come with an industry-leading 7-year warranty. It's just one more way we protect your investment and give you peace of mind for the long run.

Modal testing and the acquired test data are the basis for performing modal analysis and making conclusions on the structural dynamics of test objects. The natural frequencies of the system, modal damping ratios, and mode shapes of the object under test can be determined.

You can perform modal testing with either applied artificial excitation sources, to induce the test object to vibrate, or by having the test object running under operational conditions, and measure the in-situ vibration.

Modal testing is used for:

Troubleshooting: To reduce excessive vibration levels or to ensure resonances are kept away from excitation frequencies.

Simulation of “what if ” scenarios: Determination of forces or response to complex excitation.

Structural assembly analysis: To predict the dynamic characteristics of assembled subcomponents.

Refinement of Finite Element Model (FEM): Validation by testing on prototypes or refinement of the FE analytical model by inclusion of damping.

Modal analysis is vital to understand and optimize the inherent dynamic properties of structures - how structures and objects vibrate and how resistant they are to applied forces. The modal analysis allows machines and structures to be tested, optimized, and validated.

Test, optimize, and validate your designs for lighter, stronger, and safer constructions, less fuel/power consumption, higher comfort, and better performance. Measurements made on the structure are used to construct a complete mathematical model of the vibrational properties from which the behavior of the structure can be observed. Natural resonance frequencies of the objects and damping parameters can be calculated, and mode shapes visualized on an animated geometry of the measured objects.

The resonance frequencies together with damping ratios and mode shapes are the modal parameters of the device under test. Estimation of valid modal parameters for complex structures requires modal analysis to be performed. Determined parameters provide rich insight into the structural dynamics of the tested structure - enabling a great understanding of how to do structural optimizations.

Modal analysis is heavily used in civil engineering and industries such as aerospace and automotive, across a vast range of applications including:

Ensuring that resonances are separated from excitation frequencies

Prediction of the dynamic behavior of components and assembled structures

Optimization of the structure’s dynamic properties (mass, stiffness, damping)

Prediction of the responses due to complex excitation

Inclusion of damping in Finite Element Models

Damage detection and assessment

Dewesoft modal testing suite supports several measurement techniques or modal test configurations methods:

SISO: Single-Input Single-Output test configuration

SIMO: Single-Input Multiple-Output test configuration

MISO: Multiple-Input Single-Output test configuration

MIMO: Multiple-Input Multiple-Output test configuration

Modal tests can be performed via single reference shaker test and single reference roving hammer or roving accelerometers test. Multireference roving hammer and multireference shaker tests are also supported.

Multi-shaker tests are normally performed with many accelerometer sensors. Dewesoft modal testing suite allows you to excite complex structures by using multiple shakers and to measure and analyze on a virtually unlimited number of channels.

MIMO measurement techniques are proven and well-established methods for collecting FRF data sets. They offer some distinct advantages for the measurement and extraction of basic modal parameters especially while testing larger structures.

The main advantage of using multiple shakers is that the input-force energy is distributed over more locations on the structure. This provides a more uniform vibration response over the structure, especially in cases of large and complex structures and structures with heavy damping.

Random, burst random and sine sweep excitation signals are configured directly in the Modal Test setup screen using the Function generator, and you can use MCOH (multiple coherence) to validate your shaker setting.

Another type of roving test can also be selected, where one modal exciter (hammer or shaker) is used as the reference DOF, while one or a group of accelerometers will rove until all of the DOFs have been measured. This is also referred to as a “Roving Response Test.”

If multiple accelerometers are used, this is a Single-Input Multiple-Output (SIMO) test configuration.

Dewesoft allows you to perform your measurement with the impact hammer (single excitation point or multiple with a roving hammer) and any number of response channels.

This method is a powerful asset for in-depth assessment of the structural dynamics or structural vibrations.

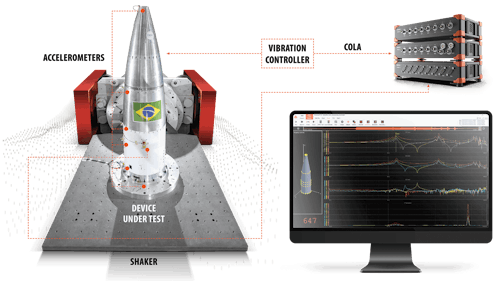

Several instruments are typically used to perform Modal Test and Modal Analysis:

One or more exciters, such as modal shakers or an impact hammer

Force transducers that acquire the input excitation signals

Accelerometers that acquire the output response signals

A data acquisition system (DAQ) device to record the test

A computer with Modal Test and Analysis software to perform calculations, display the results and create reports

Dewesoft can provide turn-key modal testing and modal analysis solutions with all the components above. See the details of available modal testing hardware below.

Dewesoft provides a range of data acquisition systems suitable for modal testing. Flexible input channel count configuration allows for different modal testing setups. High-end signal conditioning amplifiers offer perfect signal measurement with great dynamic range.

Recommended Dewesoft modal test bundles:

SIRIUS Mini model SIRIUSm-4xACC: 4-channel IEPE/piezoelectric device, perfect for connecting modal hammer and up to 3 accelerometers.

SIRIUSi-HD-16x-ACC: 16-channel IEPE device, ideal for work with a roving hammer and up to 5 triaxial accelerometers

SIRIUSi-HD-16xACC with Analog Out option: 16-channel IEPE device with 8 analog output channels. Great for working with a Modal Shaker and up to 16 IEPE accelerometers.

Our data acquisition systems are flexible by design and can be expanded to any number of input channels for no additional software cost.

All Dewesoft DAQ systems come with a 7-year warranty and FREE lifetime software updates, which makes our solution future-proof.

If high-frequency excitation content or signal-controlled testing is desired, then modal shakers are the only excitation solution. Dewesoft modal shakers are lightweight and powerful. They can operate up to 15,000 Hz, and provide force levels up to 440N with a maximum 25mm stroke.

Advantages:

Modal stinger can be easily adjusted by the through-hole armature

Lightweight, durable, portable, and easy to use

The adjustable trunnion base provides high flexibility

Up to 25mm stroke and broad frequency range

Dewesoft modal shakers can be used for Modal testing and Structural Dynamics. The series of Dewesoft modal shakers covers a wide range of structures for dynamic characterization from electronic boards and sub-components to machinery, vehicles, and aircraft, even constructions

In addition to modal shakers and vibration sensors, Dewesoft also offers a range of roving hammers with different force ranges.

Hammers up to the 440 N range are a perfect fit for modal analysis applications using DewesoftX software.

Dewesoft modal hammers are equipped with the TEDS smart sensor interface. This allows DewesoftX software to automatically detect the hammer and set the correct scaling.

Whenever a high number of measured channels is used, adding and removing the excitation and response channels process is made simple with autofill setup functionality.

Autofill functionality is enabled for:

Autofill for uniaxial and triaxial sensors (response channels)

Start node index and index increment selection

Defining the direction and sign of added channels

Grouping sensors and defining the number of groups

To get you up and running quickly, DewesoftX software offers pre-defined displays for modal testing and analysis. These predefined displays include the most often used instruments and arrangements for the acquisition and measurement process and for post-analysis of the measured data.

Each predefined display will guide you step-by-step through your modal testing process. It will track your measurement progress and allow you to reject hits, reset points, and automatically detect double hits.

Animation of your structure is enabled in all three directions, and you can view it using different projections during the measurement.

Of course, it is always possible to customize and change the default displays or define unlimited news ones.

3D geometry with animation is perfectly integrated into both the Modal Test and Modal Analysis modules and provides everything needed to build a 3D model of your structures.

With the geometry editor, you can quickly draw simple 3D structures as well as import more complex models using the UNV file format. The geometry of the measured structure is defined by objects, lines, or points. The geometry editor supports cartesian and cylindrical coordinate systems, ideal for drawing circular objects.

Structures can be animated at a single frequency in all three directions with the interpolation of non-measured points. You have the ability to animate different mode shapes and compare deflections with the non-excited structure shape. This gives a thorough visual representation of the structural dynamics.

The color of the points changes during the measurement for easier identification of the excitation and response points. The structure geometry can be rendered in different projections:

3D perspective

3D orthographic

Several 2D projections

The LSCF algorithm with curve-fitted results for the estimation of modal parameters is shown in a dedicated widget - the stabilization diagram.

You can also display the complex mode indicator function (CMIF) along with any other vector channel of your choice. AutoMAC shows the correlation between different modes. Support for synthesized FRF calculation and the ability to easily compare them with the measured FRFs is included.

Mode indicator functions (MIF), H1, and H2 estimators, power spectral density (PSD) are fully implemented in DewesoftX software and can be used in combination with other mathematical calculations.

DewesoftX data acquisition software always stores raw values of the measured data. This enables offline calculations using the raw signals from the accelerometers and hammer (or shaker) excitation points.

This is very convenient if some additional calculations need to be performed without the need for repeating the entire modal test setup.

No need to measure the entire structure at once. Different parts of the structure can be measured and stored in separate data files. DewesoftX software makes it very easy to record one data file for each point or group of points in your subject under the test.

After the measurements are done you can easily merge separate data files together to analyze and animate the entire structure and observe its behavior.

Each transfer function contains information about the response node, response direction, reference node, and reference direction.

All measured data can be exported to a variety of standard file formats. The most common and standard data formats available include UNV/UFF, Diadem, Matlab, Excel, and Text (CSV). But DewesoftX includes even more formats.

Transfer functions can be separately exported by Real, Imag, Ampl, or Phase part.

The Universal File Format (also known as UFF or UNV format) is very common in modal analysis. Depending on the header, it can contain either transfer functions, coherence, geometry, etc., or various other data. We include a modified UNV/UFF export made especially for modal tests.

See the complete list of supported export file formats.

Experimental Modal Analysis (EMA) tests can be performed both in the field and in more controlled lab environments. Testing in the lab has the advantage of a higher signal-to-noise ratio (SNR) and the ability to easily change the test setup.

When doing EMA testing, objects are excited by artificial forces, and both the input (excitation) signals and output (responses) signals are measured and used to estimate Modal Models.

Operating Deflection Shapes (ODS) is a simple way to do dynamic analysis and see how a machine or a structure moves within its operational conditions. ODS tests have no applied artificial forces and only response vibration signals are measured.

In ODS analysis the structure is only excited by the machine itself, as in real operation. Frequency ODS is the simplest method to see how a machine or structure moves during its operation, at a specific frequency.

The DewesoftX Modal suite supports ODS testing. With Frequency ODS one of the acceleration sensors has to be defined as an excitation reference signal and the other sensors as response sensors. Animation can be displayed as usual, but it works best only in areas with good coherence.

ODS is used successfully for machine conditioning monitoring and in civil engineering applications like bridges, buildings, and other structures that are difficult to excite with artificial forces.

Operational Modal Analysis is used for large civil engineering structures, operating machinery, or other structures, making use of their output responses only. These structures are always loaded by natural loads that cannot easily be controlled and measured, such as wave loads (offshore structures), wind loads (buildings), or traffic loads (bridges).

With Dewesoft ARTeMIS OMA software the modal parameters can be estimated for such operating structures where only output response data have been acquired.

The modal parameters are the mode shape, the natural frequency, and the damping ratio.

OMA is not just another name for ODS (Operating Deflection Shapes). Since OMA determines and separates noise and inputs from the output data and returns the unbiased modal information only - enabling estimations of modal models from the operational data. OMA is also referred to as output-only modal analysis, ambient response analysis, ambient modal analysis, in-operation modal analysis, and natural input modal analysis.

You can open acquired operational time Dewesoft data files (DXD) directly into the Dewesoft ARTeMIS OMA application and run the analysis.

Dewesoft modal testing and modal analysis are a great investment in your future. Our solutions are constantly being improved, and new features are being added all the time. All updates to the modal testing software suite are free of charge.

Our industry-leading 7-year warranty on Dewesoft data acquisition systems means worry-free measurements for you. We are committed to ensuring that your investment in our measurement equipment was a good one - even when the unexpected occurs.

Together with world-class data acquisition technology, Dewesoft provides the best Modal testing and modal analysis solution your money can buy.

Brochures

Manuals:

Training material:

See and browse related and compatible data acquisition products.

Modular Data Acquisition (DAQ) System

Portable 4-Channel Sound and Vibration Analyzer

Portable Data Acquisition (DAQ) Systems

Compact medium to high channel count data acquisition (DAQ) systems

High-channel-count data acquisition (DAQ) system

8-Channel Universal Data Acquisition System

General-purpose, Modal and Inertial Exciters

Sensor adapters for universal amplifiers

Award-Winning Data Acquisition and Digital Signal Processing Software

See and browse related and compatible testing solutions.

Sine Processing With Cola Signal