Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Biogas Engine Testing and Parameter Optimization

To simplify their daily work the gas engine service company Power UP GmbH is using Dewesoft measurement equipment. The company offers gas engine components exclusively developed and designed for the company with the aim of improving the lifetime of spare parts as well as the overall engine performance and efficiency.

The Dewesoft Combustion Engine Analyzer solution and Modbus communication bring the flexibility and connectivity needed.

Power UP is an energy engineering company that specializes in high-tech products and solutions for gas engines with customers in more than 40 countries. Power UP provides its own special-designed gas engine components. This service prolongs the lifetime of customer spare parts and improves engine performance and efficiency. The customers benefit from reduced maintenance costs, engine efficiency, and reliability.

Power UP´s key product components such as cylinder heads, connecting rods, pre-chambers, spark plug sleeves are produced by Power UP-Manufacturing. By optimizing existing technologies and developing new concepts, Power UP maximizes generation output while complying with the low emission guidelines.

The company also offers consulting services in gas engine solutions using alternative and efficient concepts of technology, engineering, and elaborating solutions to different markets and application requirements that will meet specific customer expectations.

The Power UP engineers continuously strive to extend the lifetime of spare parts to lower the cost of overall maintenance. The skilled sales and product support team recognize all aspects of the gas engine business. Whatever the application, they have the experience to provide solutions for commercial as well as technical challenges.

The problem and testing application

Gas engines will accompany the future energy market, as their flexibility and reliability play a vital role in an even sustainable and stable energy strategy. Such gas-driven power engines can be driven by gasses from landfill sites or industrial waste, biogas, or natural gas to generate electricity - without burning fuel, and without the exhaust emissions associated.

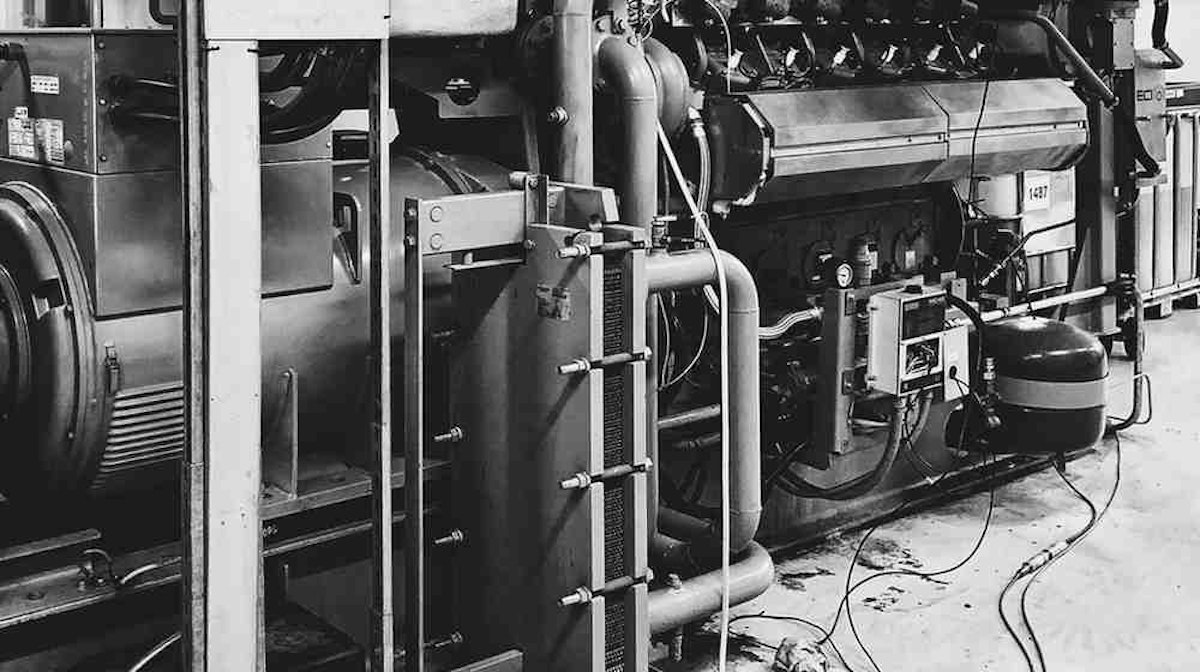

This case relates the measurement on a J312 Jenbacher 12-cylinder biogas motor/generator unit, manufactured at GE INNIO’s headquarters in Jenbach, Austria, and used at a farm for producing both electricity and heat. The J312 - the size of which is 4.7 x 1.8 x 2.3 meters - is capable of producing baseload power at the rate of 579 kW/480V/60Hz and hot water at a rate of 2454 MBTU/h (720 kW at 140 F degrees (90 C degrees).

Jenbacher gas engines have a power range of 200 kW to 10 MW and run on either natural gas or a number of other gases. They furnish onsite power, heat, and cooling for a variety of commercial, industrial, and municipal applications – particularly renewable and waste-to-energy, industrial power generation and cogeneration/CHP (combined heat and power), and oilfield power generation. More than 52,000 Jenbacher gas engines have been delivered in 100-plus countries.

The particular standard unit, in this case, has been modified by Power UP GmbH. Instead of the OEM 2-valve-cylinder head, a Power UP EVE 4-valve-cylinder head is used, boosting the electrical efficiency by 2.5%. The given Genset has an electrical output of 550 kW.

At the customer site, there is a need for an efficient, quick, and easy-to-set-up, measurement system with immediate visualization, in order to minimize engine downtime and the loss of money.

Dewesoft combustion analyzer solution

With the Dewesoft Combustion Engine Analyzer solution – a combination of DewesoftX data acquisition software with a plugin and a SIRIUS data acquisition device - data collection and visualization is just a matter of minutes.

Measurement setup

Power UP GmbH uses this data acquisition system and sensors testing setup:

SIRIUSi-8xSTG+ measurement instrument

3x DSI-CHG-50 DSI adapters

3 x AVL cylinder pressure sensor GH14D with M5 screw

1 x Ignition voltage per voltage divider

1 x Crank angle sensor installed on the engine with 164 pulses and zero pulses; connected to SIRIUS SuperCounter® input

Dewesoft X3 data acquisition and analysis software

Combustion Engine Analyzer module (Base + Advanced)

Pressure

Online calculation

Adjustable cylinders

Heat Release

Knocking

Filter

Additional analog inputsModbus Master Plugin TCP/IP

Remote network connection per VNC client

SIRIUSi Combustion Engine Analyzer systems are used for engine research, development and optimization, and even for component development and testing – such as ignition systems, exhaust systems, and valve control gear. The system consists of isolated SIRIUSi DAQ hardware and the DewesoftX data acquisition software package for measurement and analysis with a specially designed plugin for combustion engine analysis.

Such a system supports angle and time-based measurement results and uses highly sophisticated algorithms for online or offline mathematics and statistics – calculating heat release and other thermodynamic parameters. The Combustion Engine Analyzer can be fully integrated within a testbed and also supports data from other data sources like Video, CAN and CAN FD bus, XCP, and Ethernet, … Data can be exported to several different file formats.

In addition to combustion analysis, the system can be expanded to handle other measurement applications such as hybrid testing on the powertrain, noise, and vibration measurement together with synchronized video or GPS data.

Pressure sensors are used to measure the cylinder pressure of the engine. Depending on the sensor type, these can be directly connected to the SIRIUSi amplifier like any other input channel or through external signal conditioning amplifiers. Additionally, an angle sensor is needed for getting angle domain measurement results.

Measurements

For this measurement, a sampling rate of 200kS/s was used. Three of the 12 cylinders have been applied with cylinder pressure sensors. In the additional channels the ignition voltage has been specified, to get the signal in angle domain and overlay to the compression curve. The customer was impressed by the high angular resolution of down to 0,025 degrees and the easy integration of the Power UP Engine control’s Modbus TCP interface.

As the biogas motor/generator unit generates also heat and noise next to electricity, the customer connected per network and VNC Client remotely from the control room.

Analysis results

The Dewesoft instrument provides a helpful tool for the service company Power UP GmbH to adapt and optimize the motor parameters over the operational range after the engine upgrade.

Conclusion

Since the daily work of the customer requires flexibility to fit the various types of machines, the SIRIUS universal STG input module and the possibility for a future extension by DSI smart sensor adapters, and other DewesoftX software plugins (Siemens S7, OPC UA, …) provides the best interconnectivity.

The galvanic isolation of the channels guarantees safety and better signal quality for different environments.

The flexibility of the Dewesoft DAQ devices and software helps Power UP to make daily work more effective and to focus on its core know-how, parameter optimization.

Learn more about Combustion Engine Analysis Solution: