Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Merging Data Acquisition and a Real-time Control Systems

July 12, 2024

In this article we will discuss how it is possible to integrate a fully-featured data acquisition system with a real-time control system, getting the best of both worlds. At the end of this article you will:

See how DAQ and real-time control can work together seamlessly

Learn more about the IOLITE and RT series systems from Dewesoft

Understand the benefits of combining DAQ with real-time control

Are you ready to get started? Let’s go!

Introduction into data acquisition and real-time control

Until recently, there were two types of separate systems:

Real-time control systems - designed to react to events as fast as possible and with highly deterministic data. Recording high-speed data was a secondary concern.

Data acquisition systems (DAQ systems) are designed to acquire data as quickly as possible. Providing real-time data to a control system was largely or entirely unavailable.

Now, we have entered a new era, where both systems can be merged together. These systems provide the best of both worlds—highly deterministic data for control purposes and high-speed and high-accuracy data for detailed online or offline analysis.

Both are achieved using the same front end with inputs and outputs used for both purposes.

This greatly reduces the complexity and the price of the whole system since there is no longer a need for installing two sensors going to two different input channels while acquiring the same data in the same place. It also introduces a much simpler configuration, since the input channels only need to be configured once to serve both parts of the system.

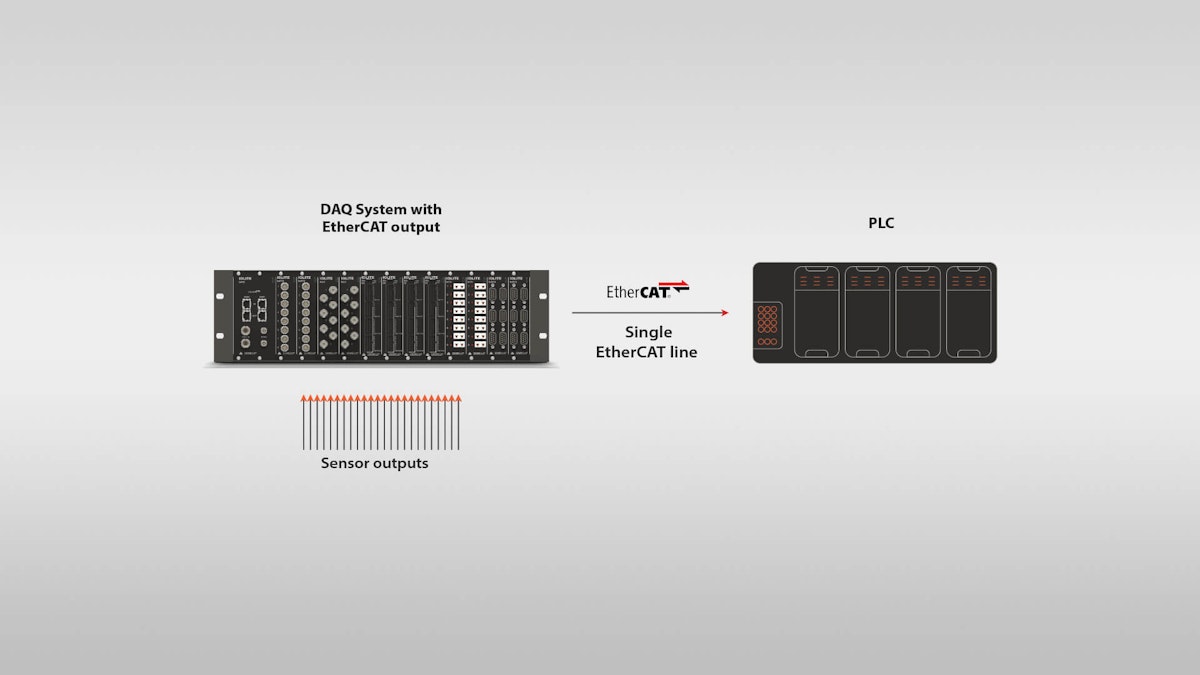

For Dewesoft’s DAQ and control systems these features come included by default. There is no longer a case where data is shared over analog lines. Our systems include a dedicated EtherCAT bus for direct connection to the real-time control system. EtherCAT connection replaces dozens of analog cables with a single digital one, eliminating the redundant analog-to-digital conversion of the signals and at the same time taking noise and interference out of the equation.

Learn more about data acquisition:

Data acquisition and real-time control applications

Here are some of the real-world applications where data acquisition and real-time control are tightly integrated:

Vehicle structural durability testbench testing (Road load data simulation)

Rocket engine testing

Factory automation / PLC networks

Motion Control and Machine control platforms

Robotics research and development

Material and baggage handling systems

Weighing Systems

Semiconductor manufacturing

Metals manufacturing (e.g., steel, aluminium mills)

Pulp & Paper manufacturing

Power plants

Wind turbines

Milling machines

Wind-Tunnel control systems

And hundreds more

Dewesoft data acquisition and control solutions

Dewesoft recently introduced a game-changing step forward in bringing the worlds of data acquisition and control closer. Data acquisition systems are equipped with two data buses that run in parallel.

The primary data bus (EtherCAT or USB) is used for full-speed buffered data acquisition to a computer’s hard drive. The secondary data bus (always EtherCAT) is used for the real-time low-latency data feed to any third-party EtherCAT-based control system.

This is a huge step in bridging the worlds of high-speed data acquisition and streaming low-latency data to a PLC controller. But the Dewesoft systems go even further. While most data acquisition systems focus 100% on handling a variety of analog input types, Dewesoft DAQs add multi-channel digital and analog outputs, so that they can directly drive actuators.

With these digital and analog outputs, Dewesoft DAQ systems can eliminate the need for PLC hardware. The EtherCAT master is implemented in the software on a computer. This master can fully control the outputs of the data acquisition system.

Amazingly, there is only one EtherCAT line between the PLC and DAQ established by connecting a single cable. This greatly reduces cabling and eliminates redundant analog-to-digital conversion of the same signals. Finally, the different worlds of control and data acquisition are combined in one elegant system.

This secondary EtherCAT data bus on Dewesoft DAQ systems can therefore be used in two ways:

As a low-latency front-end interface for any third-party EtherCAT real-time controller.

Redundant data acquisition system bus for critical DAQ applications.

Dewesoft provides two product families that implement dual bus technology for integration into real-time controllers:

IOLITE DAQ systems: IOLITE systems feature dual EtherCAT buses, one dedicated to high-speed buffered data acquisition and the other for real-time feed to controllers.

SIRIUS RT DAQ systems: the RT systems feature a data bus that is used for very high-speed buffered acquisition (up to 1MS/s) and a dedicated EtherCAT control bus for the real-time data feed.

Both IOLITE and SIRIUS RT DAQ systems like the R2rt, R4rt, and R8rt are designed for control and data acquisition applications. All IOLITE and SIRIUS RT systems replace unnecessary equipment and simplify configuration and workflows.

In order to understand how seamlessly these models work within an EtherCAT system, we have to know what EtherCAT is and how it works.

What is EtherCAT?

EtherCAT stands for “Ethernet for Control Automation Technology.” It’s a protocol that brings the power and flexibility of Ethernet to the world of industrial automation, motion control, real-time control systems, and DAQ systems.

You might be wondering why we can’t simply use Ethernet to interconnect DAQ and control systems? Ethernet is fast. It’s inexpensive. And it’s easy to implement in today’s computer-based instruments. So what is missing?

The answer lies mostly in determinism or TIME ACCURACY.

Factory automation control systems are by definition Real-time systems. Motion control, robotics, factory automation, safety protocols - all of these things require very low latency.

Unfortunately, in a conventional Ethernet network, this isn’t possible. All data is essentially “equal.” This works fine with your office computers sharing network bandwidth to access servers and printers, but not so well with real-time applications.

Learn more about EtherCAT:

EtherCAT time-stamped data

One of the most important aspects of EtherCAT is the distributed clock. Each node timestamps the data when it is received, and then stamps it again when it sends it on to the next node. So when the master receives back the data from the nodes, it can easily determine the latency of each node. Every data transmission from the master gets an I/O time-stamp from every node, making EtherCAT far more deterministic and accurate on the T axis than Ethernet can be.

Even before the EtherCAT goes to work, however, the master sends out a broadcast to all of the slave nodes on the network, who latch it when they receive it and when they send it back. The master will automatically do this as many times as necessary to reduce jitter and keep the slave nodes synchronized with each other.

This timing accuracy is extremely important in real-time control and factory automation applications. It further allows DAQ systems such as the ones available from Dewesoft to be integrated so easily into control systems.

EtherCAT’s built-in distributed clock provides excellent “jitter” performance far smaller than one microsecond (1 µs), which is equivalent to IEEE 1588 PTP (Precision Time Protocol), without the need for any additional hardware.

Connecting a DAQ system to a real-time controller

Over the years, engineers have turned to high-end data acquisition systems when the acquisition devices available for their real-time systems were not fast or accurate enough to sample an object under test. But the problem was always the same. Data acquisition systems were simply not made to connect to a PLC controller.

But engineers still found ways to do it. In general, we know three different phases of integrating DAQ systems with a real-time control system. Let’s look at each one in more detail.

Phase 1 integration with a real-time control system

In so-called Phase 1 engineers used data acquisition systems as a front-end, feeding their analog outputs into analog inputs on their network. This is referred to as a Phase 1 integration of a DAQ system with a real-time control system.

This was cumbersome and resulted in data being converted from analog to digital twice. Not a very efficient approach that resulted in a lot of cabling, configuration, and also big cost.

Phase 2 integration with a real-time control system

Later, some DAQ systems were designed with the ability to output data to the PLC digitally, via Ethernet. This was a step forward, but still not deterministic. In other words, the time accuracy was sufficient for data archiving or as a reference, but not for real-time control.

However, it did eliminate redundant A/D and D/A processes, so it can be referred to as a Phase 2 integration of a DAQ system with a real-time control system.

Phase 3 integration with a real-time control system

So how can we get to a phase 3 integration, where the DAQ system has a deterministic integration with the real-time control system?

In fact, the DAQ system needs to become part of the network, not just an asynchronous peripheral. Instruments using EtherCAT are divided into two groups:

Control systems and

Measurement systems.

Control devices such as PLCs are masters on the EtherCAT network, whereas measurement devices like data acquisition systems are slaves.

By installing an EtherCAT slave port into their DAQ systems, Dewesoft eliminates the limitations of Phase 1 and Phase 2 integrations, and brings the DAQ system directly into the real-time control system:

This truly is a Phase 3 implementation, because the DAQ system is a true slave node on the EtherCAT network, sending time-stamped (deterministic) data in the direction of the host. There is no more redundant A/D conversion or non-deterministic Ethernet data.

Problem solved? Yes, but this is actually just the beginning. Dewesoft DAQ systems like the SIRIUS RT and IOLITE models can also stream much higher-speed data in parallel via USB (or Ethernet) to a secondary computer.

There are applications where it is desired that the DAQ system should provide BOTH the deterministic data requested by the EtherCAT master AND high-speed data to a second computer for high-end analysis.

This is exactly what Dewesoft RT systems provide in the real-world example below.

Real-world application: Implementation of Dewesoft R8rt systems with an MTS real-time master

In the system shown above, R8rt DAQ systems are used with an MTS road simulator test bench for testing the durability of car and truck suspension systems. It consists of four corners, each having 6 degrees of freedom. Over a hundred analog input and output channels were used by the MTS FlexTest controller for actuator control.

There are two master computers used:

The MTS real-time master uses EtherCAT to control the road simulator in real-time. The Dewesoft R8rt DAQ slaves provided deterministic measurement data from the accelerometers to the test-bench controller via EtherCAT.

The Dewesoft master records the streams of higher-speed data from the Dewesoft R8rt for advanced post-mission analysis.

It is interesting to note that the Dewesoft RT models can provide extremely high-speed data via USB in parallel with the deterministic data across EtherCAT at the usually lower speeds requested by the EtherCAT master.

It is also possible to send high-speed data across Ethernet to a master PC running the DewesoftX NET add-on when USB is not practical due to distance. In this case, the data can also be safely stored on the Dewesoft hardware to guard against network data interruptions.

An additional 96 channels were used for measuring the response of the specimen to correlate the loads on the test bench to the real road load data. Signals from those channels were acquired by two Dewesoft R8rt data acquisition systems. Each of the R8rt systems includes 6 SIRIUS strain gauge amplifier slices and is streamed over EtherCAT to the MTS FlexTest controller.

But the Dewesoft systems were not only used to test vehicles on the road load simulator! They were also used as the fully-featured DAQ systems that were installed in the car and collected the raw data on the test track in the first place!

The fact that they serve this double duty is a huge money saver for the customer, both in terms of eliminating the need to buy two separate systems, but also in the savings of user training, configuration management, and spares.

And by sending data digitally instead of by analog cables, the customer could eliminate kilometres of analog cables.

Read full Dewesoft case studies on data acquisition and control integration:

Software EtherCAT masters

It is possible to connect Dewesoft DAQ and Control systems to a computer host running a 3rd party real-time PLC software. Dewesoft DAQ and control system are currently compatible with the following 3rd party masters:

Furthermore, Dewesoft systems can even drive the actuators, providing the real-time hardware control needed for the system.

Channel expansion via EtherCAT master port

IOLITE has dual redundant EtherCAT ports, meaning that it can also receive synchronized data from other EtherCAT-equipped DAQ systems, like the SIRIUS EtherCAT and KRYPTON models.

Dewesoft data acquisition and control systems

Dewesoft provides two product families that implement dual bus technology for integration into real-time controllers:

IOLITE: Industrial data acquisition and control systems with dual, redundant EtherCAT buses.

SIRIUS RT: High-end data acquisition systems with high-speed sampling and high dynamic signal acquisition. Systems feature a USB data bus that is used for very high-speed buffered acquisition (up to 1MS/s) and a dedicated EtherCAT control bus for the real-time data feed.

KRYPTON: Rugged, robust, and distributed data acquisition modules compatible with 3rd party EtherCAT masters. Systems offer an IP67 degree of environmental protection.

IOLITE rack DAQ and control systems

IOLTE data acquisition and real-time control systems can provide both real-time control and feedback monitoring systems. IOLITE systems are equipped with two fully independent EtherCAT buses that run in parallel.

The primary EtherCAT bus provides perfectly synchronized and full-speed data acquisition via DewesoftX software. IOLITE can stream any number of input and output channels at high speeds to the computer's internal hard drive.

IOLITE's secondary EtherCAT bus can be used in two ways:

A low-latency front-end interface for any third-party EtherCAT compatible real-time controller

A redundant data acquisition system bus for critical DAQ applications

To summarize, IOLITE is unique among DAQ systems in that it can be used both for high-speed DAQ and real-time control via either a hardware or software real-time PLC.

The IOLITE systems are available in several chassis configurations:

IOLITE R12 is a 19-inch rack-mounting system with 12 slots for multi-channel input modules. Using 8 channel modules you can achieve up to 96 channels per chassis.

IOLITE R8 is a desk-top system with 8 slots for multi-channel input modules. Using 8-channel modules you can achieve up to 64 channels per chassis.

IOLITE R8R more rugged version of the IOLITE R8 chassis that can withstand higher temperature and shock ranges.

IOLITE I/O modules

Several multi-channel I/O modules are available for the IOLITE systems:

| Module | Type | Channels | ADC | Isolation | Note |

|---|---|---|---|---|---|

| IOLITEr-6xSTG | Universal and strain gage input | 6 | 24-bit delta-sigma ADC @ 20 kS/s | Differential | Compatible with all DSI adapters for multiple sensor types |

| IOLITEr-8xSTGS | Strain gage input | 8 | 24 Bit oversampled sigma-delta, 20 kS/s, with AAF | Differential | Full / Half/ Quarter bridge |

| IOLITEir-8xTH | Universal thermocouple input | 8 | 24-bit delta-sigma ADC @ 100 S/s | 1000 V | Supports K, J, T, R, S, N, E, C, U, B types |

| IOLITEir-8xRTD | Universal PTx temperature, resistance, and voltage input | 8 | 24-bit delta-sigma ADC @ 100 S/s | 1000 V | Supports PT100, PT200, PT500, PT1000, PT2000 |

| IOLITEir-8xLV | Isolated low voltage inputs | 8 | 24-bit oversampled SAR ADC @ 20 kS/s | 450 V | Ranges: ±100 V, ±10 V |

| IOLITEr-16xLV | General-purpose voltage module | 16 | 24-bit delta-sigma ADC @ 20 kS/s | / | Ranges: ±200 V, ±10 V |

| IOLITEir-8xLA | Current input module | 8 | 24-bit oversampled SAR ADC @ 20 kS/s | 450 V | Ranges: ±20 mA, ±2 mA |

| IOLITE-16xAO | Analog output module | 16 | / | / | Output voltage ±10 V |

| IOLITEr-32xDI | Digital input module | 32 | 20 kS/s | 1000 V | |

| IOLITEr-32xDO | Digital output module | 32 | / | 1000 V | Maximum switching voltage 50 V |

| IOLITEr-8xDI-4xDO | Digital Input and Output Module | 8 input4 output | 40 kS/s | 1000 V | |

| IOLITEr-4xCNT | Digital Counter Module | 4 | Timebase 100 Mhz | ±25 V continuous | Bandwidth 10 MHz |

Learn more about IOLITE DAQs:

SIRIUS RT data acquisition systems

SIRIUS is the flagship of the Dewesoft product line. They combine state-of-the-art data acquisition technology with unmatched signal conditioning and A/D conversion. SIRIUS modules are available to handle virtually all signals and sensors, from strain gages to low and high voltages, thermocouples, RTDs, charge and IEPE accelerometers, microphones, current, LVDTs, counters and encoders, and many more.

Patented DualCoreADC® technology provides a dynamic range of up to a remarkable 160 dB. Connects to your computer via USB or EtherCAT®. Adding the ruggedized SBOX computer provides a local host with removable storage, a display interface, and more.

Dewesoft’s SIRIUS RT systems are equipped with so-called DualMode functionality. DualMode means that they can simultaneously stream data at the highest possible rates (up to 1 MS/s) into the computer (either integrated or external via USB) running DewesoftX software and in parallel stream data across EtherCAT at reduced rates with extremely low latency.

Dewesoft RT systems come in several chassis variations:

R2rt

R2rt-HUB

R4rt

R4rt-HUB

R8rt

R8Rrt

SIRIUS EtherCAT modular

SIRIUS R2rt and R2rt-HUB

The SIRIUS R2rt is a compact data acquisition system with a built-in data logger and a powerful data processing computer called SBOX. The R2rt systems can be configured with up to two SIRIUS amplifier slices, for either:

16 DualCoreADC input channels

16 HS (high-speed) channels

32 HD (high-density) channels

The R2rt-HUB system offers the same chassis for 2 amplifier slices, but replaces the integrated SBOX computer with a USB hub for a connection to an external PC computer via USB.

SIRIUS R4rt and R4rt-HUB

The SIRIUS R4rt is a compact data acquisition system with a built-in data logger and powerful data processing computer. It can be configured with up to four SIRIUS slices, for either:

32 DualCoreADC channels

32 HS (high-speed) channels

64 HD (high-density) channels.

The 42rt-HUB system offers the same chassis for 4 amplifier slices but replaces the integrated SBOX computer with a USB hub for a connection to an external PC computer via USB.

SIRIUS R8rt and R8Rrt

The SIRIUS R8rt and R8Rrt are powerful benchtop data acquisition systems with a built-in data logger and powerful data processing computer. The R8rt chassis offers maximum channel count configurations in single compact chassis.

SIRIUS R8rt systems can be configured with up to eight SIRIUS amplifiers slices, for either:

64 DualCoreADC channels

64 HS (high speed) channels

128 HD (high-density) channels

The R8Rrt chassis is additionally upgraded to withstand high shocks and 3 gRMS random vibrations for 10 minutes in each direction.

SIRIUS EtherCAT modular

SIRIUS modular DAQ systems offer both high-speed USB and EtherCAT outputs. They can provide the data to the EtherCAT master and in parallel, record much higher-speed data to a separate computer running DewesoftX data acquisition software.

SIRIUS can also be connected to the IOLITE or SIRIUS RT systems, for channel expansion. The DualMode operation allows serving data to the EtherCAT master and to a separate computer running DewesoftX software. This runs in parallel and is also fault-tolerant. If the computer with Windows operating system running DewesoftX were to completely fail, SIRIUS would continue sending data to the EtherCAT master via the secondary EtherCAT data bus.

SIRIUS amplifier modules

DualCoreADC amplifiers

| Module | Type | Channels | ADC | Isolation | Available connectors |

|---|---|---|---|---|---|

| UNI | Universal input (Voltage, IEPE, Bridge, Potentiometer) | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9 |

| ACC | IEPE and voltage input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | BNC, TNC |

| CHG | Charge, IEPE, and voltage input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | BNC, TNC |

| STG | Universal and strain input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9, L2B7f, L2B10f |

| STGM | Universal and strain input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9, L2B7f, L2B10f |

| LV | General low voltage input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9, BNC, BANANA |

| HV | High-voltage input | 8 | Dual 24-bit delta-sigma anti-aliasing filter @ 200 KS/s | CAT II 1000 V | BANAN |

High-Density Amplifiers

| Module | Type | Channels | ADC | Isolation | Available connectors |

|---|---|---|---|---|---|

| HD-ACC | IEPE and voltage input | 16 | 24-bit delta-sigma with anti-aliasing filter @ 200 KS/s | 1000 V | BNC |

| HD-STGS | Universal and strain input | 16 | 24-bit delta-sigma with anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9, L1B10f |

| HD-LV | General low voltage input | 16 | 24-bit delta-sigma with anti-aliasing filter @ 200 KS/s | 1000 V | DSUB-9, BNC |

High-Speed Amplifiers

| Module | Type | Channels | ADC | Isolation | Available connectors |

|---|---|---|---|---|---|

| HS-ACC | IEPE and voltage input | 8 | 16-bit SAR @ 1 MS/s | 1000 V | BNC |

| HS-CHG | Charge, IEPE, and voltage input | 8 | 16-bit SAR @ 1 MS/s | 1000 V | BNC, TNC |

| HS-STG | Universal and strain input | 8 | 16-bit SAR @ 1 MS/s | 1000 V | DSUB-9 |

| HS-LV | General low voltage input | 8 | 16-bit SAR @ 1 MS/s | 1000 V | DSUB-9, BNC, BANANA |

| HS-HV | High-voltage input | 8 | 16-bit SAR @ 1 MS/s | CAT II 1000 V | BANANA |

KRYPTON EtherCAT DAQ modules for harsh environments

Most DAQ hardware on the market is designed for office or light industrial use. But there are applications where the DAQ equipment must be located in harsh environments. For example:

High temperatures up to 85°C (185° F)

Cryogenic temperatures down to -40° C/F

High shock and vibration up to 100 g

Water spray or immersion

High dust concentration

Most DAQ instruments are not designed to withstand even one or two of those extreme environmental conditions. Based on these requirements, Dewesoft developed the KRYPTON series of DAQ instruments.

KRYPTON systems meet IP67 standards for water and dust, meaning that they can withstand not only water spray but total immersion in 1 meter (39 inches) of water for 30 minutes. They are completely sealed against dust and other small particles.

Being filled with a thermally insulating rubber, KRYPTON modules can withstand a wide range of temperatures from -40° to 85° C (-40° to 185° F). KRYPTON modules are found in hot and cold weather automotive tests, on rocket engine test stands, and in factories where ice cream and another cold (or hot) foods are made.

KRYPTON modules are also designed to handle 100g shock and high-vibration environments. This can be a serious requirement in many applications where large vibrating machinery is found, or testing rockets and other large force-producing machines.

KRYPTON modules are interconnected via a single rugged EtherCAT cable that carries data, power, and synchronization. The cables can be up to 100 m (328 feet) long so that engineers can distribute the modules where the signals are. This might be across a bridge or a large factory floor.

Many modules can be connected this way. KRYPTON is available in multi-channel modules as well as single-channel KRYPTON ONE modules for ultimate flexibility.

KRYPTON multi-channel DAQ modules

These multi-channel modules are available for the KRYPTON system:

| Module | Type | Channels | ADC | Isolation | Note |

|---|---|---|---|---|---|

| STG | Universal and strain gage input | 3 and 6 | 24-bit oversampled SAR @ 20 kS/s | Differential | Compatible with all DSI adapters for multiple sensor types |

| TH | Universal thermocouple input | 8 and 16 | 24-bit delta-sigma ADC @ 100 S/s | 1000 V | Supports K, J, T, R, S, N, E, C, U, B types |

| RTD | Universal PTx temperature, resistance, and voltage input | 8 | 24-bit delta-sigma ADC @ 100 S/s | 1000 V | Supports PT100, PT200, PT500, PT1000, PT2000 |

| ACC | Voltage and IEPE piezoelectric input | 4 and 8 | 24-bit 24-bit delta-sigma with anti-aliasing filter @ 20 kS/s | / | Supports TEDS sensors |

| LV | General-purpose voltage module | 4 and 8 | 24-bit oversampled SAR @ 20 kS/s | 1000 V | ±50 V and DC coupling |

| LA | Current input module | 8 | 24-bit oversampled SAR @ 20 kS/s | 1000 V | ±20 mA and 4-20 mA current loop |

| DIO | Digital I/O module | 8 and 16 | 20 kS/s | 1000 V | Available with either 8 ins + 8 outs, or 16 ins + 16 outs |

KRYPTON single-channel modules

For the ultimate in modularity, single-channel KRYPTON modules allow you to place your signal conditioners anywhere needed, right at the signal source. KRYPTON ONE modules are interconnected exactly like multi-channel KRYPTON modules and on the same EtherCAT network.

Available single-channel KRYPTON modules:

| Module | Type | Channels | ADC | Isolation | Note |

|---|---|---|---|---|---|

| STG | Universal and strain gage input | 1 | 24-bit SAR with anti-aliasing filter @ 40 kS/s | Differential | Compatible with all DSI adapters for multiple sensor types |

| ACC | Voltage and IEPE piezoelectric input | 1 | 24-bit SAR with anti-aliasing filter @ 40 kS/s | / | Supports TEDS sensors |

| HV | Universal thermocouple input | 1 | 24-bit SAR with anti-aliasing filter @ 40 kS/s | CAT III 600 V, CAT II 1000 V | |

| LV | General-purpose voltage module | 1 | 24-bit oversampled SAR @ 20 kS/s | 1000 V | ±50 V and DC coupling |

| LA | Current input module | 1 | 24-bit oversampled SAR @ 20 kS/s | 1000 V | ±20 mA and 4-20 mA current loop |

| TH-HV | Universal PTx temperature, resistance, and voltage input | 1 | 24-bit delta-sigma ADC @ 100 S/s | CAT III 600 V, CAT II 1000 V | |

| DI | Digital input module | 4 | 40 kS/s | Galvanic isolation CH, GND | TTL / CMOS Voltage Levels |

| DO | Digital output module | 4 | / | Galvanic isolation CH, GND | |

| AO | Analog output module | 1 | / | / | Full Scale Output Range ±10 V |

EtherCAT cables for harsh environments

Well, if the DAQ hardware is waterproof, dustproof, and can withstand -40° temperatures, the cables must also be able to withstand these environmental extremes, too. Otherwise, the system will fail simply because of the cables.

Accordingly, Dewesoft has developed EtherCAT cables that are used to interconnect their KRYPTON series of harsh environment DAQ systems. In the video below we show the cables being frozen to -40°C and how they maintain their flexibility.

Summary

We hope that you now understand the benefits of Dewesoft’s Phase 3 integration of DAQ systems with a real-time controller. High-speed DAQ systems such as the Dewesoft IOLITE, SIRUS RT systems, and expansion modules like KRYPTON and SIRIUS modular have completely changed the landscape for providing deterministic data to a control system.

This final step was a big one. With Dewesoft’s unique implementation of EtherCAT into high-end DAQ technology, engineers can now realize these distinct advantages when designing their systems:

High performance: EtherCAT is 100 Mb/s

Deterministic: real-time operation with synchronization ~ 1 ns

Flexible: Dewesoft slave DAQs can also stream at an even higher speed to a separate host, far above the EtherCAT maximum speed

Affordable: direct connection of IOLITE to EtherCAT system eliminates go-between hardware. IOLITE can also eliminate hardware master controllers and connect to software PLCs.