Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

ISO Lane-Change Manoeuvre Test (ISO 3888)

March 4, 2023

This application note shows how Dewesoft products provide an effective and flexible solution for quick validation and measurement of ISO lane-change test (ISO 3888). The mobile measurement instruments and the easy-to-setup software are used for checking and visualization of measured parameters to guide the driver through the measurement and check the results online.

Introduction

The client, a car manufacturer in Italy, designing, testing and manufacturing different vehicles including cars asked for help at shorting time of testing and improving quality of results at vehicle dynamic maneuvers, which includes online check of results and gives direct feedback to the driver either if the test was successful or they have to repeat it.

One of such maneuvers is the double lane change maneuver, which is used worldwide to evaluate the handling and safety of vehicles and their key components. Therefore various parameters are being checked by the test engineer, but for a driver it’s crucial, to have an online check if the test has passed or failed (cones were hit or not). Tested with pure GNSS device and combination of GNSS with AHRS, to compare results.

Measurement setup

Data acquisition system

DEWE-43 compact, mobile data acquisition system with universal analog inputs, counter/encoder/digital inputs and CAN bus inputs

Sensors

DS-IMU2 inertial measurement unit with RTK upgrade ->1 cm accuracy

DS-RTK-BASE (GPS based unit) to provide RTK accuracy for vehicle

Software

DewesoftX polygon plugin with special lane change setup

Polygon setup

Polygon objects (fixed and moving cones) have been set up according to the ISO 3888 standard. The advantage of using moving cones is that the driver can quickly change the car and edit vehicles length/width. With having those parameters, the configuration of the maneuver is changed according to the standard (width of the track,..).

Several additional calculations have been added to evaluate different parameters (like velocity, roll,..) versus distance on the track, which is shown in results.

By having certain lines as Start and Stop trigger, it is possible to reduce the file size and capture only the points of interest.

Analysis

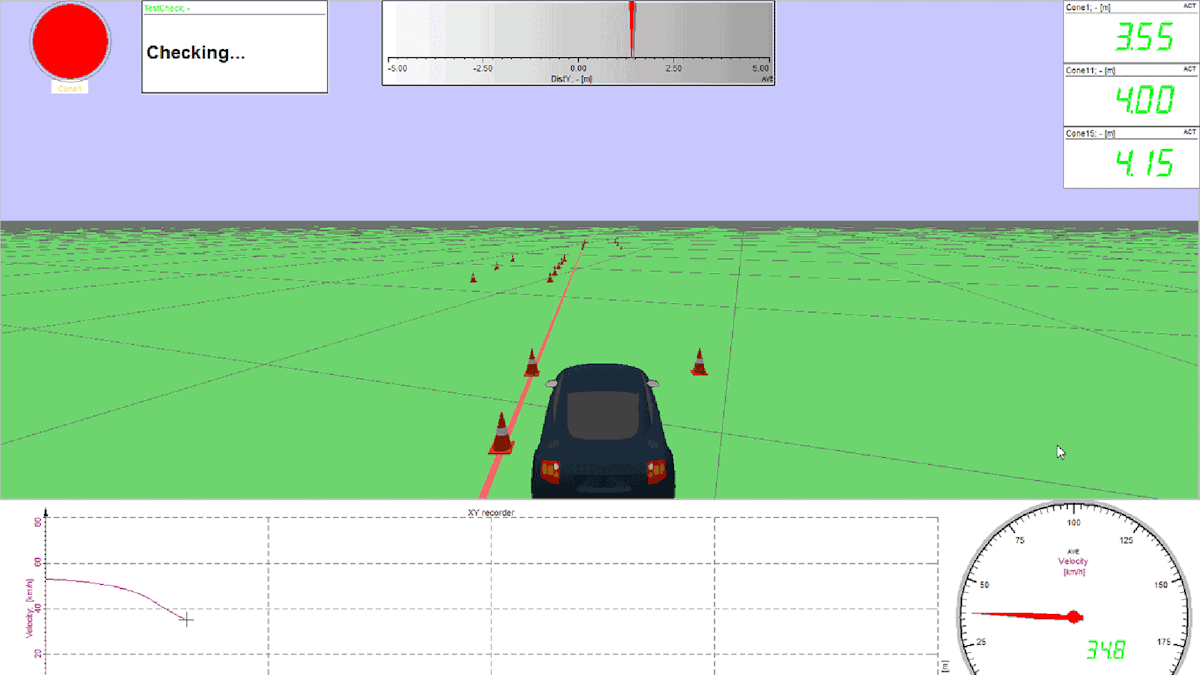

Measurement screen combined together with analysis for online checking

The display below is included in a Lane Change setup. It shows online validation of the data, so the driver has direct feedback if the test has passed or failed, which is located in the top left of the screen. The 2D display shows the graph of velocity during the track (Velocity/PosX on the track). At the same time, it’s also possible to display the graph of PosY/PosX, to see the lane change maneuver.

In addition, we were measuring the vehicle CAN bus to have information on RPM, steering angle and other vital analysis parameters.

Conclusion

The measurement with DS-IMU2 with 1 cm RTK upgrade has shown a very accurate position (centimeter level) and 3-axis velocity results. Due to this it can be used for regulation and going even further due to the inertial platform it can be used also for research and development, where additional parameters as Roll, Angular velocity in Z-axis and Ay for evaluation of vehicle handling are needed.

After teaching the drivers and performing several tests, with different cars, time of testing, in comparison with setting manual cones and measure complete track every time, has been reduced for at least 30%, which is a great improvement.