Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

The List of Wind Tunnel Testing Facilities

February 9, 2023

This article provides an interactive list of wind tunnel testing facilities around the world. It will provide useful information to:

Learn what wind tunnels are and why we need them

See an interactive world map of wind tunnels

Find useful information about each wind tunnel

Introduction

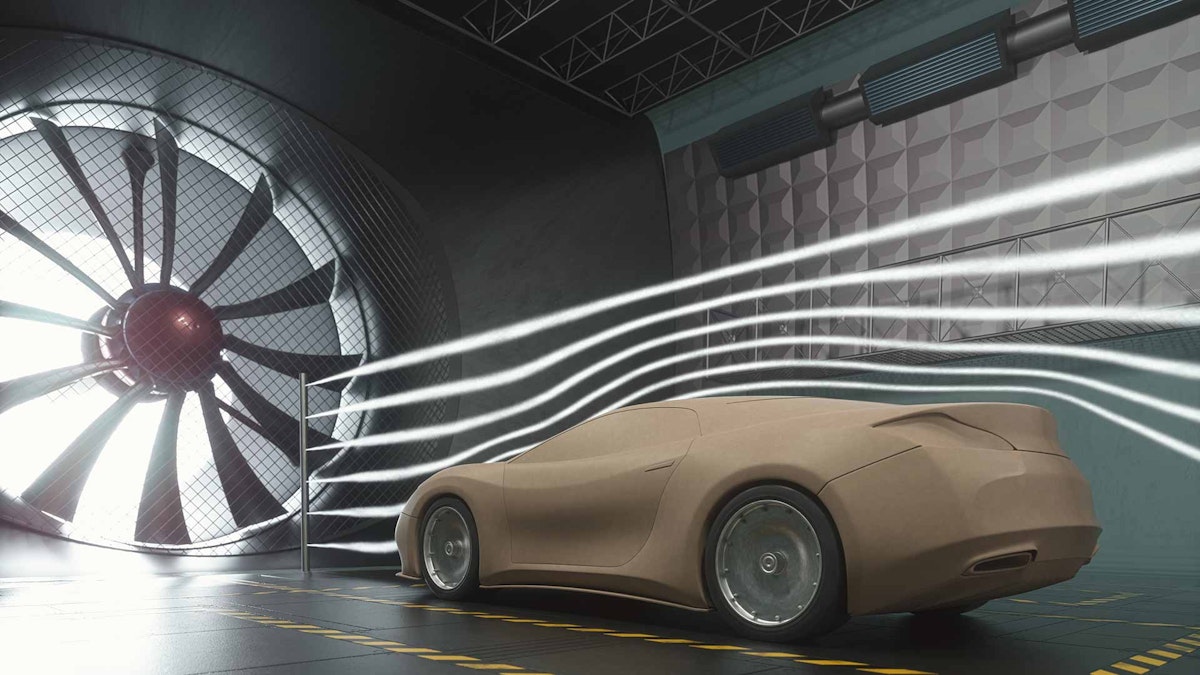

Wind tunnels are facilities that enable real-world simulation of how air passes around an object. Testing models in wind tunnels provide the data to verify or enhance computer simulations. Designers and engineers use such testing to study and assess aerodynamics and fluid flow phenomena. Wind tunnels enable them to validate the efficiency and durability of anything from architectural elements to cars and aircraft.

World map of wind tunnel testing facilities

List of wind tunnel testing facilities by country

| Name | Contact | Services |

|---|---|---|

| Wind Tunnel Facilities in Australia | ||

| The Monash University Wind Tunnel Facility | Alliance Ln Clayton VIC 3800 david.burton@monash.edu +61 3 9905 5865 | For vehicle development in the areas of aerodynamic, aeroacoustic, and cooling analysis in both road and racing car design. Airplane, UAV and micro UAV, truck, train, building, cycling, yachting, and various other aerodynamic tests. |

| Adelaide Wind Tunnel | Building 21 (The Palace) Thebarton Campus 35-37 Stirling Street Thebarton SA 5031 | An industrial-scale wind tunnel. Wind engineering and aerodynamics testing. Turntable and force balance (wind engineering) Support stings with load cells Hot-wire, Pitot, and Cobra Probe anemometry (1-, 2- and 3-component). Flow visualization. Laser diagnostics (LIF, PIV) 3D scanning laser vibrometer. Acoustic instrumentation. Dedicated staff offering technical support and expert consultation. |

| Wind Tunnel Facilities in Austria | ||

| Rail Tec Arsenal vehicle testing station | Paukerwerkstraße 3 A-1210 Wien +43 (0)1 256 8081 - 0 | Large Climatic Wind Tunnel (large CWT). Icing Wind Tunnel (IWT). Small Climatic Wind Tunnel (small CWT). |

| Wind Tunnel Facilities in Belgium | ||

| Von Karman Institute for Fluid Dynamics Wind Tunnels | Waterloosesteenweg 72 B-1640 Sint-Genesius-Rode +32 2 359 96 11 | High-speed and low-speed wind tunnels. Longshot Hypersonic Gun Tunnel. Supersonic Transonic Wind Tunnel. Continuous High-Speed Cascade Wind Tunnel. Supersonic Wind Tunnel. Hypersonic Wind Tunnel. 3-Meter Diameter Wind Tunnel. Low-Speed Wind Tunnel. Icing Wind Tunnel. Adaptive Wall Wind Tunnel. Low-Speed Wind Tunnel Waablief. |

| Wind Tunnel Facilities in Brazil | ||

| Federal University of Minas Gerais Wind Tunnel | Av. Antônio Carlos, 6.627 Campus Pampulha - 31270 901 Belo Horizonte | For the Aerospace Engineering testing. 485 horsepower engine and capable of generating winds of more than 400 kilometers per hour to evaluate the aerodynamic aspects of a body, such as the forces acting on it. |

| University of São Paulo Wind Tunnel | Rua da Reitoria, 109 Campus da Cidade Universitária CEP 05508-900 São Paulo | Study of wind loads in buildings and structures and the analysis of the dispersion of pollutants in the air. Safety of off-shore oil platforms, heliports, bridges, buildings, ship towers, and high voltage towers. |

| University of vale do Paraíba Wind Tunnel | Av. Shishima Hifumi 2911 São José dos Campos SP, 12244-000 | Subsonic Wind Tunnel. Used by students of the Aeronautical and Space Engineering Course. |

| UFABC Wind Tunnel | Avenida dos Estados 5001 - Bairro Santa Terezinha - Santo André CEP: 09210-580 | Supersonic wind tunnels for aerospace studies |

| Instituto de Aeronáutica e Espaço/DCTA | Praça Marechal Eduardo Gomes 50 Vila das Acácias 12228-900 São José dos Campos/SP marcosmss4@fab.mil.br (12) 3947-6502 | The TA-2 is a closed-circuit subsonic wind tunnel. The dimensions of the test section are 3 m x 2.1 m x 3 m. The maximum flow velocity is 140 m/s and the turbulence intensity is on the order of 0.5%. Below its test section is the aerodynamic balance, capable of measuring 3 models and 3 test moments. Tests of aerodynamic forces and moments. Pressure distribution tests. Flow Visualization, Particle Image Velocimetry, Hot Wire Anemometry. |

| Instituto de Pesquisas Tecnológicas | Av. Prof. Almeida Prado 532 - Butantã São Paulo - SP, 05508-901 | Largest subsonic wind tunnel in all of Latin America, which allows meteorologists, for example, to simulate catastrophes such as Hurricane Catarina and observe how a building reacts in terms of aerodynamics. |

| Wind Tunnel Facilities in Canada | ||

| ACE Climatic Wind Tunnel | 2000 Simcoe Street North Oshawa, Ontario L1G 0C5 905 721 8668 | Full scale: automotive, motorsport, cycling, skiing, architectural, transit, truck, and product development. Aerodynamic testing. Heating, ventilation, and air conditioning (HVAC) testing in vehicles. Product quality control. Snow mitigation (architectural). Thermodynamic testing. Wind turbines. |

| RWDI Wind Tunnels | 600 Southgate Drive, Guelph Ontario 4P6 +1 519 823 1311 | Wind engineering. Aerodynamic shaping for sports. Aerodynamic shaping for structures. Bridge aerodynamics. Offshore floating and production, wind, and current loading. Wind effects on façade systems. Wind effects on solar energy systems. Wind effects on structural systems. Wind loads on industrial structures. |

| Wind Tunnel Facilities in Denmark | ||

| Poul la Cour Tunnel DTU Wind Energy | Building 331, Frederiksborgvej 399 4000 Roskilde contact@plct.dk +45 23814667 | Aerodynamic and aeroacoustic blade section/airfoil tests for wind turbine blades. |

| Force Technology Wind Tunnels | Park Alle 345 DK-2605 Brøndby +45 43 25 00 00 | Closed-circuit wind tunnel (WT1). Boundary-layer wind tunnel (WT2). Wide boundary-layer wind tunnel (WT3). Truncated wide boundary-layer wind tunnel (WT4). Climatic Wind Tunnel (WT5). |

| Wind Tunnel Facilities in France | ||

| CSTB Jules Verne Wind Tunnel | 11 Rue Henri Picherit 44300 Nantes cape@cstb.fr +33 (0)2 40 37 20 67 | A climatic wind tunnel. Buildings and Components testing. Civil engineering, renewable energies, automotive, rail transport, industrial machines, and equipment defense. |

| ICARE EDITH supersonic wind tunnel | 1C, avenue de la Recherche Scientifique CS 50060 45071 – Orleans Cedex 2 +33 2 38 25 77 17 | Fundamental research on shock waves. Aerodynamic and aerothermal behavior of probes and models. Fluidic thrust vectoring of the supersonic nozzle. |

| ICARE MARHY wind tunnel | 1C, avenue de la Recherche Scientifique CS 50060 45071 – Orleans Cedex 2 +33 2 38 25 77 17 | No limit to running time. Fundamental and applied research of fluid dynamic phenomena in rarefied compressible flows. Aerodynamic and aerothermal behavior of probes and models. Plasma flows control in rarefied and super/hypersonic flows. |

| ONERA Modane-Avrieux Winds Tunnels | Chef Lieu 73500 Avrieux +33 4 79 20 21 22 | S1MA Continuous-flow wind tunnel, atmospheric. S2MA Continuous-flow wind tunnel, variable pressure. S3MA Blow down wind tunnel. S4A Blowdown hypersonic wind tunnel with axisymmetric nozzles. S4B TPS calibration. BD2 Nozzle thrust measurement. R4-1 Air intake testing research programs. |

| ICARE PHEDRA (Experimental platform FAST) | 1C, avenue de la Recherche Scientifique CS 50060 45071 – Orleans Cedex 2 +33 2 38 25 77 17 | Supersonic blower with high enthalpy and continuous operation. Fundamental research on high enthalpy flows. Out-of-equilibrium flow dynamics. Experimental database of planetary atmospheric inputs: Mars, Earth, Titan, Venus. Study of the aerodynamic and aerothermal behavior of space probes. Plasma flows control by MHD. |

| Wind Tunnel Facilities in Germany | ||

| ETW - European Transonic Windtunnel | Ernst-Mach-Strasse 51147 Köln +49 (2203) 609-116 | Simulation of the actual high-lift and high-speed flight conditions of modern transport aircraft. Testing in pure nitrogen flows with a temperature down to -163°C. Transonic. |

| Large Amplitude Multi-Purpose (LAMP) Vertical Wind Tunnel Bihrle Applied Research | Blumenstraße 285 86633 Neuburg an der Donau +49 8431 40797 | Vertical, Subsonic, High AOA, Static or body-axis oscillatory. |

| The Trisonic Windtunnel Munich (TWM) | Werner-Heisenberg-Weg 39 85577 Neubiberg sekretariat.lrt7@unibw.de +49 89 6004-2536 | Is a blow-down wind tunnel for sub-, trans- and supersonic flows. Particle Image Velocimetry (PIV). Pressure-Sensitive Paint (PSP). Infrared-Thermography. Deformation measurement technique. 96 static pressure sensors (10 Hz). 40 dynamic pressure sensors (100 kHz). 4-color Schlieren-system. |

| DNW Niedergeschwindigkeits-windkanal Braunschweig | Lilienthalplatz 7 38108 Braunschweig info@dnw.aero +31 527 248505 | The NWB in Braunschweig is a closed-circuit low-speed wind tunnel of the atmospheric type, located on the premises of the DLR. Aeroacoustic investigations. Database creation and configuration studies for aircraft, cars, and trucks. Engine integration., dynamic testing, air intake tests, air exhaust simulation. |

| DNW Transsonischer Windkanal Göttingen | Bunsenstraße 10 37073 Göttingen info@dnw.aero +31 527 248505 | Closed-circuit, continuous, variable density sub-, trans- and supersonic wind tunnel with three exchangeable test sections. 2D airfoil tests with flow control devices (e.g. vortex generators, suction, blowing, ventilation, trailing edge devices, MEMs), helicopter blades. Configuration studies, data set determination of 3D models (missiles, fighters, spacecraft). Air intake surveys for fighters and missiles. Drag bookkeeping with through-flow ducts. Dynamic tests: free and forced pitch oscillation of dynamically scaled flexible 2D and half-models; flutter and limit cycle oscillation; dynamically linked substructures (nacelle, flap); forced and free-to-roll maneuvers. Air data system and probe calibration. |

| Wind Tunnel Facilities in India | ||

| National Wind Tunnel Facility Indian Institute of Technology Kanpur | Kalyanpur Kanpur-208016 alakeshm@iitk.ac.in +91512259 - 7062 (O) | Testing at wind speed up to 80 m/sec. Support for national R&D needs in areas of Aerospace and non Aerospace applications. |

| Wind Tunnel Facilities in Israel | ||

| IAI Wind Tunnels Center | שדרות רשות שדות התעופ, כביש 40 | Subsonic, tri-sonic, and hypersonic tunnels - covering velocity range from 0 to 12 Mach. Aerodynamics Tests for civil and military programs. |

| Wind Tunnel Facilities in Italy | ||

| GVPM Politecnico Wind Tunnel | Via La Masa, 34 20156 Milano windtunnel@polimi.it +39 02 2399 8073 | Building, bridges, rail, aeronautical, general-purpose. Low turbulence test section. Open jet test section. Boundary layer test section. |

| CIRA Icing Wind Tunnel | Via Maiorise snc 81043 Capua info@cira.it +39 0823 623 111 | Ice and aerodynamic testing. Support both low and high subsonic aerodynamic aircraft/rotorcraft research by increasing Reynold’s number with the use of cooling (up to -40 °C) and the variation of static pressure (up to 1.45 bar). |

| Pininfarina Wind Tunnel | Via Ferrero 1 10095 Grugliasco +39 011 7091356 | Ground Effect Simulation System. Turbulence Generation System. Aerodynamics and aeroacoustics of vehicles. Wind engineering, sport, and others. |

| CRIACIV Boundary Layer Wind Tunnel University of Florence - Civil and Environmental Engineering Dept. | Piazza G.Ciardi 25 59100 Prato criaciv.fi@gmail.com +39 0574 602558 | Building, bridges, general-purpose Low turbulence test section (<0.75% Turb.Intensity) Max speed 30 m/s Boundary layer test section |

| Wind Tunnel Facilities in Japan | ||

| Japan Aerospace Exploration Agency (JAXA) | 7-44-1 Jindaiji Higashimachi, Chofu-shi Tokyo 182-8522 0422 40 3000 | 6.5mx5.5 Low-speed Wind Tunnel designed to examine the aerodynamic characteristics of aircraft at low speeds. 2mx2m Low-speed Wind Tunnel can be used for various tests from basic aerodynamic measurements to the tests simulating flutter conditions using gust wind cart. 2mx2m Transonic Wind Tunnel can produce transonic flow up to Mach number of 1.4. 1mx1m Supersonic Wind Tunnel can create a supersonic flow between Mach 1.4 and 4.0 0.5m / 1.27m Hypersonic Wind Tunnel consisting of two hypersonic wind tunnels, can be used to study aerodynamic characteristics and aerodynamic heating for hypersonic vehicles. 750kW Arc-Heated Wind Tunnel/110kW Inductively-coupled-plasma Wind Tunnel can create high-enthalpy conditions for re-entry vehicles and are used for the heating testing of thermal protection system for re-entry vehicle with the high-enthalpy flow. 0.8mx0.45 High Reynolds Number Transonic Wind tunnels create transonic flow with a high Reynolds number. 0.6mx0.6m Transonic Flutter Wind Tunnel is used to examine transonic flutter phenomena. 0.65x0.55m Low-Turbulence Wind Tunnel has been used for various studies, such as the studies on boundary‐layer transition and the tests on the aerodynamics of unmanned aircraft systems as well as for the development of advanced measurement technology like pressure‐sensitive paint. |

| Wind Tunnel Facilities in Mexico | ||

| LemAT Túnel de Viento | Av. Antonio Delfin Madrigal 668, C.U. Coyoacán, 04369 Ciudad de México +52 525 556 233 500 | Simple return circuit. Civil engineering, architecture, mass transport. Evaluation of the general operation of the tunnel. Test calibration. Instrumentation, sampling, and acquisition. |

| ESIME Ticomán Laboratorio de Aerodinámica | Calz. Ticomán 600, San José Ticoman, Gustavo A. Madero 07340 Ciudad de México esimeticoman@ipn.mx +52 55 5729 6000 | This highly specialized laboratory studies the interaction of the wind with various components of the environment such as aircraft, land vehicles, civil structures, among others. Two low-speed wind tunnels capable of reaching 130 km/h. A supersonic wind tunnel capable of reaching 1,800 km/h. |

| Wind Tunnel Facilities in the Netherlands | ||

| DNW High-Speed Tunnel | Anthony Fokkerweg 2 1059 CM Amsterdam info@dnw.aero +31 527 24 8520 | Closed-circuit, variable density, continuous wind tunnel with slotted top and bottom test section walls (12% open). Configuration studies, database creation (civil and military transport aircraft, fighters, spacecraft) Engine integration studies by means of Turbofan Propulsion Simulators (TPS) for air turbines or propellers. Air exhaust simulation with compressed air. Internal and external air intake surveys. |

| DNW Large Low-Speed Facility | Voorsterweg 31 8316 PR Marknesse info@dnw.aero +31 527 24 8520 | Closed-circuit, atmospheric, continuous low-speed wind tunnel with one closed wall and one configurable (slotted) wall test section, and an open jet. Configuration studies, database creation (civil and military transport aircraft, fighters, helicopters, spacecraft, cars, and trucks). Engine integration studies with air-powered simulators. Turbofan-powered aircraft by means of TPS. Propeller-driven aircraft. Air exhaust simulation with compressed air. Air intake surveys for fighters and helicopters. Aeroacoustic and performance testing on rotorcraft models. Aeroacoustic testing on full-scale aircraft components (landing gears, wings). Aeroacoustic investigations on scaled turbofans. Full-scale cars and trucks (drag and aeroacoustics). |

| TUDewlft Wind Tunnels | Cornelis Drebbelweg 3 2628 CM Delft w.a.timmer@tudelft.nl +31 (0)15 27 88279 | High-Speed Wind Tunnels offer the capabilities of testing in the transonic and supersonic regimes. TST-27 Transonic/Supersonic, ST-15 Supersonic, ST-3 Supersonic, HTFD Hypersonic, Compressor Plant. Low-Speed Wind Tunnels offer test sections of different sizes (largest 2.85 x 2.85 meters) and various speeds in the subsonic regime up to 120 meters/second: Open Jet Facility, W-Tunnel, M-Tunnel, Low Turbulence Tunnel, A-Tunnel. |

| The wind tunnel (WT) on campus of Eindhoven University of Technology (TU/e) | Eindhoven University of Technology 5612 AZ Eindhoven s.g.gillmeier@tue.nl +31 6 28524708 | Aerodynamic and boundary layer research on static and moving objects. The WT is a closed-circuit atmospheric boundary layer wind tunnel (ABLWT) with a total length of 46 m and a test section length of 27 m. The test section is 3 m wide and 2 m high. Tests can be conducted at reference velocities ranging from 0 - 30 m/s. |

| Wind Tunnel Facilities in New Zeland | ||

| Insol Wind Tunnel | 34 Onslow Street, PO Box 231, Invercargill enquiries@insol.co.nz 03 216 3287 | Able to generate flow velocities of up to 200km/h, the wind tunnel is designed to fit large 1:1 scale models over its 3m diameter turntable. With full variable speed control over the 4 centrifugal fans, maximum control of wind speeds allow for low-speed acoustic testing as well as high-speed structural tests. |

| Wind Tunnel Facilities in Portugal | ||

| The Structural Aerodynamics Laboratory (UADinE) Wind Tunnels | Avenida do Brasil, 101 1700-066 Lisboa lnec@lnec.pt +351 218 443 000 | Aeronautical wind tunnel tests with closed-loop. Boundary-layer - wind tunnel tests with open-loop. Open jet - wind tunnel tests with 1.6 m in diameter. |

| Wind Tunnel Facilities in Russia | ||

| Central Aerohydrodynamic Institute TsAGI | 1 Zhukovsky Street Moscow Region, 140180 ved@tsagi.ru (8)7 (495) 556 31 22 | Experiments in wind tunnels, flight simulators, and test installations. Tests of propellers and propfans Static strength and fatigue tests for airframes under varying conditions of heat and pressure. Wind tunnel tests combined with complex physical analysis. Analytical and experimental research on structural dynamics and aeroelasticity phenomena. Concepts for flight control systems. |

| Wind Tunnel Facilities in South Africa | ||

| CSIR Wind Tunnels | Meiring Naude Rd Brummeria, Pretoria, 0184 JMorgan@csir.co.za +27 012 841 2738 | Low-speed wind-tunnel continuous, single return wind tunnel with a closed test section. Seven-meter wind tunnel open-circuit tunnel powered by 28 axial flow fans of 30 kW each. Medium-speed wind tunnel 20 MW electric motor drives a three-stage axial compressor with variable guide vanes and stator blade angles for accurate Mach number control High-speed wind-tunnel trisonic, blowdown wind tunnel equipped with a color Schlieren system for flow visualization. |

| Wind Tunnel Facilities in Spain | ||

| ITER Wind Tunnel | Pol. Ind. de Granadilla, s/n 38600 - Granadilla de Abona difusion@iter.es 0034 922 747 700 | Aerodynamic tunnel for civil tests Closed-circuit and one closed-test room. The power plant is composed of 9 fans, each one of 22 kW which each produces 24m3/s. |

| INTA Linear Wind Tunnel | Ctra de Torrejón a Ajalvir, km 4 28850 Torrejón de Ardoz +34 915 206 433 | 500 mm diameter tunnel, six meters long, that moves the test bench at variable speeds under different ambient conditions. |

| Universidad Europea Wind Tunnel | C/ Tajo, s/n. Urb. El Bosque 28670 Villaviciosa de Odón Madrid +34 91 740 72 72 | A closed horizontal axis wind tunnel that occupies a space of 12 x 5.6 m2, has 2 test chambers a high speed of 0.9 x 0.9 m2 and another low speed one of 1.80 x 1.80 m2, with maximum wind speeds of 150 and 50 Km/h. Smoke equipment for streamline visualization. |

| Wind Tunnel Facilities in Switzerland | ||

| RUAG Wind Tunnels | Schiltwaldstrasse 6032 Emmen aerodynamics@ruag.ch +41 58 48 37842 | Aerodynamic analyses and investigations for customers from the aerospace, automotive, and industrial sectors. LWTE (Large Wind Tunnel Emmen) with a 7m x 5m test section for 70m/s. AWTE (Automotive Wind Tunnel Emmen) with a 2.5m x 1.5m test section and a rolling road system for 60m/s. |

| Wind Tunnel Facilities in Turkey | ||

| Turkish Aerospace subsonic wind tunnel facility | Fethiye Mahallesi Havacılık Bulvarı No:17 06980 Kahramankazan/Ankara +90 (312) 811 18 00 | Three different t.est sections, large, small and open. 6.4m x 4.8m large solid wall and open-jet test sections. 4.7m x 3.9m small solid-wall test sections. Development of indigenous, rotary-wing, and fixed-wing aircraft. |

| Ankara Wind Tunnel | Emniyet Mahallesi Gazeteci Yazar Muammer Yaşar Bostancı Caddesi İncitaşı Sokak No:67/ B Yenimahalle/Ankara hasan.basci@tubitak.gov.tr +90 (312) 590 92 91 | Closed-circuit, horizontal loop, atmospheric and closed test chamber wind tunnel operating at low subsonic speeds |

| Wind Tunnel Facilities in the United Kingdom | ||

| Aircraft Research Association (ARA) | 2000 Manton Ln Bedford MK41 7PF business@ara.co.uk +44 (0) 1234 324600 | Transonic closed circuit. A continuous flow wind tunnel. Computational Aerodynamics. Design and Manufacture. Experimental Aerodynamics. |

| NWTF Transonic/Supersonic | Northampton Square London EC1V 0HB +44 20 7040 5060 | Is used for aerospace-related studies, given the high velocity that can be reached in the relatively large (for its speed) test section. Shock-wave-boundary-layer interaction, turbine blade aerodynamics, rocket science, and the effect of heat exchange. Equipped with a full optical access section. |

| NWTF Atmospheric Boundary Layer (ABL) | Birmingham +44 12 1414 3344 | Can generate approximately uniform flows or simulate the turbulence and velocity profiles of an atmospheric boundary layer (ABL) through the use of spires and roughness elements. |

| NWTF Supersonic / Transonic 1&2 | The Old Schools, Trinity Ln Cambridge CB2 1TN +44 12 2333 7733 | Two identical supersonic tunnels. |

| NWTF 8ft x 6ft Low Speed | College Rd, Cranfield, Wharley End Bedford MK43 0AL +44 12 3475 0111 | Quadrant for sting mounting High-pressure air system for flow control (blowing and suction). |

| NWTF 10ft x 5ft Low Speed | Exhibition Rd, South Kensington London SW7 2BX +44 20 7589 5111 | A highly reconfigurable temperature-controlled facility with two test sections offering a wide range of features covering just about any study involving airflow. Provides facility for aerodynamic development and safety evaluation studies of road and race cars, aircraft, buildings, and structures. |

| NWTF 8ft x 4ft Low Speed | College Rd, Cranfield, Wharley End Bedford MK43 0AL +44 12 3475 0111 | It is equipped with multiple smoke filament flow seeding, high-speed video, surface oil flow. Hydrocarbon analyser for plume dispersion studies. |

| NWTF Icing Tunnel | College Rd, Cranfield, Wharley End Bedford MK43 0AL +44 12 3475 0111 | This facility is used to understand the details of how ice forms on aircraft, wind turbines, and other structures. |

| NWTF Aeroacoustic | Bristol BS8 1TH +44 11 7928 9000 | Consists of a very quiet closed-circuit wind tunnel and a large anechoic chamber. |

| NWTF DeHavilland Low-Speed Wind Tunnel | Glasgow G12 8QQ +44 14 1330 2000 | Dynamic stall. Rotor rigs have been developed and used in this tunnel. Sting support system. |

| NWTF Supersonic | Exhibition Rd, South Kensington London SW7 2BX +44 20 7589 5111 | The tunnel operates in a combined blow-down/suck-down arrangement: typical run times are of the order of 10 s and can be performed at a high repetition rate of up to 30 tests per day. |

| NWTF Low Turbulence | Northampton Square London EC1V 0HB +44 20 7040 5060 | This tunnel is exclusively used for studies on laminar-turbulent transition. |

| NWTF Hypersonic | Exhibition Rd, South Kensington London SW7 2BX +44 20 7589 5111 | Numerous fundamental axis-symmetric rigs (e.g. compression ramp/cowl) for studies of SWBLI, with and without shock-induced separation. |

| NWTF Hypersonic | Oxford Rd Manchester M13 9PL +44 16 1306 6000 | Blow-down. |

| NWTF T6 Piston Reflected Shock | Oxford OX1 2JD +44 18 6527 0000 | Europe’s highest speed wind tunnel, capable of producing flows in excess of 20 km/s. It is a multi-mode facility, capable of operating either as a reflected shock tunnel, an expansion tunnel, or a shock tube. |

| NWTF High-Density Tunnel | Oxford OX1 2JD +44 18 6527 0000 | It operates either as a Ludwig tunnel or a Light Piston Compression Heating facility, producing cold hypersonic flow conditions with test times long enough to investigate unsteady flow effects. |

| NWFT Low Density | Oxford OX1 2JD +44 18 6527 0000 | It is a rarefied flow facility, with the ability to produce flows with high Knudsen numbers representative of those experienced in the slip regime. The facility is continuous and is capable of measuring aerodynamic coefficients by use of a magnetic suspension balance. |

| NWFT R.J. Mitchell | Hartley Library B12, University Rd, Highfield Southampton SO17 1BJ | Rolling road (up to 40m/s) with dual-stage boundary layer suction. Dynamic model motion and acquisition systems have been developed previously and a new system is currently being manufactured. Rotor rigs have been developed and used in this tunnel as well as propeller/rudder rigs. Rolling road (up to 40m/s) with dual-stage boundary layer suction. Dynamic model motion and acquisition systems have been developed previously and a new system is currently being manufactured. Rotor rigs have been developed and used in this tunnel as well as propeller/rudder rigs. |

| NWTF Anechoic | Hartley Library B12, University Rd, Highfield Southampton SO17 1BJ | Arc of far-field microphones to obtain comprehensive directivity information. Simultaneous microphone array and laser diagnostics. It is able to conduct airframe noise and loads tests, high speeds train research as well as some specialist propulsive (engine) research. |

| NWTF Environmental Flow (EnFlo) | Stag Hill, University Campus Guildford GU2 7XH | A wide range of atmospheric boundary layer conditions could be simulated at a laboratory scale applied to the study of flow and dispersion processes. |

| HORIBA MIRA Full-Scale Aerodynamic Wind Tunnel | Watling St Nuneaton CV10 0TU +44 (0)24 7635 5000 | For automotive/motorsport product development and provides a repeatable, cost-effective solution for the aerodynamic test and development for a wide range of vehicles. Testing a variety of non-automotive products that require safety testing under extreme wind speeds. |

| Wind Tunnel Facilities in the United States | ||

| A2 wind tunnel | 117 Godspeed Ln NC 28115 704 799 1001 | A full-scale general-purpose open-return wind tunnel. Full-scale race car. Motorcycle. Bicycle. |

| Lockheed Martin Low-Speed Wind Tunnel (LSWT) | Marietta, GA | Aeronautics. Full-Scale Automotive. V/STOL Aircraft. General Purpose. |

| Lockheed Martin High-Speed Wind Tunnel (HSWT) | 9301 Skyline Rd, Dallas TX 75208 tim.j.fennell@lmco.com (972) 603-2751 | Aerodynamic force and moment testing. Jet interaction testing of maneuvering thrusters. Flutter analysis including digital high-speed video. Store separation testing to include free separation and captive trajectory. Pressure measurements (up to 240 locations). Surface flow visualization. Inlet performance evaluation. Jet engine base-flow simulation using high-pressure gas. Propulsion (wind tunnel and bench testing). Spin/roll damping and Magnus testing. Dynamic stability testing. |

| AeroDyn Wind Tunnel | 135 Godspeed Ln Mooresville NC 28115 704 799 1856 | Full-scale NASCAR racecars. Closed-jet. |

| Auto Research Center (ARC) | 4012 Championship Drive Indianapolis, IN 46268 sales@arcindy.com 317 291 8600 | Subsonic research and development including 50% scale model automotive rolling road, wind turbine design and optimization, and cycling. |

| Boeing Wind Tunnels | 7755 E Marginal Way S Seattle, WA 98108 bts@boeing.com | Vertical/Short Takeoff and Landing Wind Tunnel. Boeing Subsonic (low-speed) Wind Tunnel - BVWT. Boeing Transonic Wind Tunnel - BTWT. Polysonic (supersonic) Wind Tunnel - PSWT. Icing wind tunnel - BRAIT. Aero-acoustic Facility - LSAF. Propulsion testing facilities. |

| Cal Poly's Low- Speed Wind Tunnel | N Perimeter Rd San Luis Obispo, CA 93405 aero@calpoly.edu 805 756-7172 | Scale model testing. Aerospace. Automotive. IR industry. |

| Calspan Test Solutions | 13825 Schmidt Lake Rd Plymouth, MN 55446 | Channel 10 Transonic Wind Tunnel: the Channel 10 test facility is an atmospheric inlet blow-down wind tunnel capable of delivering velocities in the test section over a range from Mach 0.1 to 1.05 and a specific set point at Mach 1.2. Channel 5 Transonic Wind Tunnel: the Channel 5 test facility is an atmospheric inlet blow-down wind tunnel capable of delivering velocities in the test section up to Mach 1.2 external flow. Channel 9 Hypersonic Test Facility: the Calspan Channel 9 Hypersonic Test Facility is presently configured with a 15 inch diameter freejet nozzle for aerodynamic flow studies. Mach numbers may be set between M = 6.5 and M = 9.5. Multi-year updates to the facility slated to begin in 2024. |

| Glenn L. Martin Wind Tunnel | 8167 Paint Branch Dr, College Park MD 20742 | Low speed: scale model testing, automotive, aerospace. Vertical takeoff aircraft. Unmanned air vehicles. Conventional airplanes. Ground vehicles. Sport aerodynamic testing. Buildings, antennas, and other structures. Submarine and surface ships. |

| Modine Wind Tunnels | 1500 De Koven Ave Racine WI 53403-2552 | Modine’s wind tunnels are capable of testing a wide range of products, from heavy-duty vehicles to outdoor light fixtures or signs. Capability to simulate climatic conditions that can raise or lower the temperature as needed in minutes, from the extremes of the North Pole to the hottest desert conditions. Control of the humidity, airflow speed, and vehicle speed. |

| NASA Ames Research Center | Mountain View California | Premier wind tunnel facilities that have a broad range of testing capabilities to customers from industry, DOD, other government agencies, and academia. 11-by 11 Foot Unitary Plan Transonic Wind Tunnel. 9-by 7 Foot Unitary Plan Wind Tunnel. National Full Scale Aerodynamics Complex. Planetary Aeolian Laboratory. 7-by 10-foot Wind Tunnel (operated by U.S. Army). |

| NASA Glenn Research Center | 21000 Brookpark Road Cleveland, OH 44135 (216) 433-4000 | 10×10 Abe Silverstein Supersonic Wind Tunnel for testing supersonic propulsion components from inlets and nozzles to full-scale jet and rocket engines. 1×1 Supersonic Wind Tunnel specializes in conducting fundamental research in supersonic and hypersonic fluid mechanics, supersonic-vehicle-focused research, and detailed benchmark quality experiments for computational fluid dynamics (CFD) code validation. 8×6 Supersonic Wind Tunnel operates either in an aerodynamic closed-loop cycle, testing aerodynamic performance models, or in a propulsion open-loop cycle that tests live fuel-burning engines and models. 9×15 Low-Speed Wind Tunnel can simulate takeoff, approach, and landing in a continuous subsonic environment. Hypersonic Tunnel Facility that tests large-scale hypersonic air-breathing propulsion systems. Icing Research Tunnel supports the development of tools and methods for simulating the growth of ice on aircraft surfaces as well as the development and certification of ice protection systems. |

| NASA Langley Research Center | Hampton VA 23666 larc-dl-public-inquiries@mail.nasa.gov (757) 864-1000 | 0.3-Meter Transonic Cryogenic Tunnel is used for testing airfoil (wing) sections and other models at Reynolds numbers. 8-Foot High-Temperature Tunnel is a combustion-heated hypersonic blowdown-to-atmosphere wind tunnel that provides simulation of flight enthalpy. 14- by 22-Foot Subsonic Tunnel is an atmospheric, closed-return tunnel that can reach a velocity of 348 ft/s. 16-Foot Transonic Tunnel is an atmospheric, closed-circuit tunnel 20-Foot Vertical Spin Tunnel is a closed-throat, annular return wind tunnel operating at atmospheric conditions. Low-Turbulence Pressure Tunnel is a single return, a closed-circuit tunnel that can operate from 1 to 10 atmospheres. Transonic Dynamics Tunnel is specifically dedicated to investigating flutter problems of fixed-wing aircraft. Unitary Plan Wind Tunnel is a closed-circuit, continuous flow, variable density supersonic tunnel with two test sections. |

| San Diego Wind Tunnel | 3050 Pacific Hwy San Diego, CA 92101 mdine@lswt.com 619 665 9463 | Major airframers, bicycle manufacturers, and professional athletes. |

| Texas A&M Oran W. Nicks Low-Speed Wind Tunnel | 1775 George Bush Dr. West College Station, Texas 77845 lswt@tamu.edu 979 845 1028 | Is a large-scale, subsonic wind tunnel. Scale aircraft, UAV, rocket, missile, academic research, automotive, motorsport, cycling, skiing, architectural, transit, truck, product development 0-200MPH. |

| TitanX Jamestown Vehicle Climatic Wind Tunnel | Jamestown, NY | Climatic testing of vehicle systems and entire trucks. |

| Kirsten Wind Tunnel (KWT) | University of Washington, Box 352400 Seattle, WA 98195-2400 aafrontdesk@uw.edu 206 543 1950 | Scale-model aircraft, scale-model ground vehicles, UAVs, bicycles, motorcycles, racing yacht keels. |

| The University of Washington Dept. of Aero&Astro 3x3 | University of Washington, Box 352400 Seattle, WA 98195-2400 aafrontdesk@uw.edu 206 543 1950 | An open-loop facility. |

| Virginia Tech Stability Wind Tunnel | 407 Barger St Blacksburg, VA 24060 devenport@vt.edu +1 540 231 4456 | Aerodynamic capabilities increased by the addition of a removable anechoic test section allowing for full-scale aero-acoustic testing. |

| Wind Shear's Full Scale, Rolling Road, Automotive Wind Tunnel | 1050 Ivey Cline Rd Concord, NC 28027 | Wind shear. |

| Fluid Dynamics Testing Facilities (FDTF) | Providence RI 02912 kbreuer@brown.edu | Engineering, aerodynamic testing as well as animal flight testing. |

| Propulsion Wind Tunnel Facility | Wattendorf Memorial Hwy Tullahoma, TN 37388, | 16-foot transonic (16T), 16-foot supersonic (16S), and the aerodynamic 4-foot transonic (4T) wind tunnels. Aerodynamic and propulsion integration testing of large-scale aircraft models. |

| Walter H. Beech Wind Tunnel | 1845 Fairmount St. Wichita, Kansas 67260-0093 john@niar.wichita.edu (316) 978-5481 | Commercial companies, government agencies, and educational institutions with the facilities, equipment, and research staff to meet their aerodynamic testing and research needs. Subsonic (M ≤ 0.3), Closed Return, Atmospheric, Closed Test Section with Active Heat Exchange. An atmospheric, return type, closed-throat, subsonic wind tunnel with a test section 7 feet high, 10 feet wide, and 12 feet long. Air speeds in the test section can reach in excess of 230 mph. |

| IBHS Research Center | 5335 Richburg Road, Richburg, SC 29729 South Carolina cbreedlove@ibhs.org (803) 789-8000 | Main Chamber structure is a designed wind tunnel that is exceptionally large; 6 stories tall and 145 feet wide by 145 feet long. Can test full-scale one- and two-story residential and commercial buildings in a controlled, repeatable fashion for highly realistic windstorms, wind-driven rain, hailstorms, and wildfire ember storms utilizing the unique features. The large test chamber is identified by its enormous wall of 105 fans - each nearly 6 feet in diameter and equipped with a 350 HP engine. Together the fans can replicate realistic weather conditions including Category 1, 2, and 3 hurricanes (with winds up to 130 mph), extra-tropical windstorms, wind-driven rain conditions, and straight-line windstorms (also called Derechos). The COMET (Component Materials Evaluation Testing) apparatus consists of a single fan, similar to those in the wall of fans, which is used outdoors to test individual components of a structure such as roof shingles. |

What is a wind tunnel?

A wind tunnel is a duct or tube-like test setup in which powerful electric fans can generate air flowing at a known velocity. The consistent airflow is led past models or full-size objects to investigate the flow and effect of airstreams and optimize their design.

The air in the tunnel moves around the stationary test object to simulate the same relative movement in the real life, while the aerodynamic forces acting on the object, such as drag and lift, are measured.

The model or object is often placed on a turntable or a rotating mobile platform to allow studies of wind impact from multiple directions.

The wind tunnels are made for testing and predicting wind load for all kinds of structures moving through air or affected by wind force: bridges, vessels, aircraft, buildings, wind turbines, and numerous offshore structures, or parts and components of these. Even objects like parachutes, vehicle trailers, or tennis balls are tested in wind tunnels.

The characteristics of the airflow around the object tested can be visualized by flow visualization techniques including photographing or video recording injected smoke or dye, or oil flowing on the object.

Wind tunnel tests verify engineers' calculations and identify areas for improvement in their designs. Advantages of the wind tunnel technique include:

Accurate results to minimize assumptions

Well-controlled flow circumstances

Adjustment of variables at will, and economy

Easy reproduction of the experimental conditions

Accurate data generation for validating the Computational Fluid Dynamics (CFD) simulations and field measurements.

How do wind tunnels work?

Without going into too much detail it is best to watch this video explanation of how wind tunnels work.

Wind tunnel history - when did it start?

In a trial to test windmill sails, the British civil engineer John Smeaton in 1759 stated a need for artificial wind. Smeaton developed the concepts and data which became the basis for the Smeaton pressure coefficient, the lift equation used by the Wright brothers. During the late 1800s wind tunnels appeared when many attempted to develop successful flying machines.

Frank H. Wenham (1824-1908), a Council Member of the Aeronautical Society of Great Britain, is generally credited with designing and operating the first wind tunnel in 1871. The tunnel was built by John Browning, an optician, and located at Penn's Marine Engineering Works in Greenwich, England. The tunnel was 3.7 meters (12 feet) long and 45.7 centimeters (18 inches) square. Another early documented wind tunnel was built by the Wright brothers at the end of 1901 for flight tests of their gliders.

Even if the first wind tunnel in Great Britain was operated by a compressed air ejector the following wind tunnels used the air moved by a fan disposed upstream of the wind tunnel's test section. The change to suction is an important step in wind tunnel development. When the fan is disposed downstream of the test section and it no longer interferes with the model, which guarantees the quality of flow.

Wind tunnel structure - how does it work?

Three main criteria that are commonly used to define wind tunnels are maximum achievable speed, flow uniformity, and turbulence level. Therefore, the design aim of a wind tunnel, in general, is to get a controlled flow in the test chamber, achieving the necessary flow performance and quality parameters.

There are five basic parts of the wind tunnel: The Settling Chamber, the Contraction Cone, the Test Section, the Diffuser, and the Drive Section. During a test, the test object is placed in the test section of the tunnel, and the air is made to flow past it. Various types of instrumentation are used to determine the forces on the model.

In some wind tunnel tests, the aerodynamic forces and moments on the model are measured directly. The model is mounted in the tunnel on a special machine called a force balance. The output from the balance is a signal that is related to the forces and moments on the model. Balances can be used to measure both the lift and drag forces.

The balance must be calibrated against a known value of the force before, and sometimes during, the test. Force measurements usually require some data reduction or post-test processing to account for Reynolds number or Mach number effects on the model during testing.

Four air properties affect the way it flows by an object: viscosity, density, compressibility, and temperature. With the model mounted on a force balance, lift, drag, lateral forces, yaw, roll, and pitching moments over a range of angles of attack can be measured.

Types of wind tunnels

The type, size, and wind force of a wind tunnel depend on the size and character of the object for testing and the desired flow conditions. Some wind tunnels can accommodate full-scale models but, for practicality and cost reasons, most are built to fit miniaturized models.

Open-circuit wind tunnels (Eiffel type)

Open circuit or open return wind tunnels do not directly re-circulate air. Rather, the air is drawn in from the laboratory environment, passes through the test section, and is returned back to the lab through the tunnel exhaust.

The wind tunnel of the Eiffel type has an open and no air recirculation. The blower is at the end of the tunnel in an outflow diffuser. In this procedure, the flow guidance happens by means of a smoothing chamber with a rectifier and sieves, and a nozzle. Named after Gustave Eiffel, who in 1909 built a small wind tunnel at the foot of the Eiffel Tower to study the effect of the wind on more precise fixed points.

Closed-circuit wind tunnels (Prandtl type)

In the closed return or closed return tunnel, the air is conducted from the exit of the test section back to the fan by a series of turning vanes. Exiting the fan, the air is returned to the contraction section and back through the test section.

Built at the University of Göttingen, in Germany, by Ludwig Prandtl in 1909. After being sucked downstream of the test section, the air is guided through four successive bends and then readmitted upstream of the collector. This type of wind tunnel called the Prandtl wind tunnel – or Göttingen wind tunnel – leads to better fuel efficiency and provides controlled test conditions (pressure, temperature, humidity).

Modern wind tunnels are often a combination of these types, Prandtl's closed circuit and Eiffel's open circuit with a diffuser.

Wind tunnel classification

Wind tunnels are generally classified by the amount of speed they can produce as either low-speed (Low-Speed Wind Tunnels (LSWT)) or high-speed. They are further classified as:

Subsonic wind tunnels (80 percent of the speed of sound) - these are furtherly split into “Incompressible subsonic” (between Mach 0 and about 0.3) and “Compressible subsonic” (between about Mach 0.3 and about 0.8).

Transonic wind tunnels – between Mach 0.8 and 1.2 - about the speed of sound.

Supersonic wind tunnels – between Mach 1 and 4 - up to 6 times the speed of sound.

Hypersonic wind tunnels – Mach is greater than 4 - 5 - up to 12 times the speed of sound.

Hypervelocity wind tunnels – more than 12 times the speed of sound.

Specialized wind tunnels

High enthalpy wind tunnels are designed to study the flow of air around objects moving at speeds much faster than the local speed of sound (hypersonic speeds). "Enthalpy" is the total energy of a gas stream, composed of internal energy due to temperature, the product of pressure and volume, and the velocity of flow.

Atmospheric entry wind tunnels or plasma wind tunnels use plasma to simulate aerodynamic heating and a high Mach number state at reentering into the atmosphere. It reproduces re-entry conditions by heating gas to several thousand degrees Celsius, at air flows seven times the speed of sound and with stagnation pressures as high as 50 atmospheres. Varying Reynold numbers indicate the steady or turbulent fluid flow past the object or in the tunnel.

Climatic wind tunnels have the capability of recreating climatic conditions such as solar radiation, temperature, and humidity, e.g., rainfall, snowfall, and icing. It is used for testing things such as wind turbines, bridge cables, or fans in heating, ventilation, and air conditioning (HVAC).

Shock tubes or blow-down wind tunnels produce airflow by rapid discharge of a high-pressure storage tank or by suction from an evacuated reservoir. They can replicate and direct blast waves simulating actual explosions and their effects. Shock tubes are used to investigate compressible flow phenomena and gas-phase combustion reactions.

Wind tunnel applications

Designers and engineers use wind tunnel modeling and testing to simulate and assess the aerodynamics around objects and to validate the efficiency and durability of anything from architectural elements to cars and aircraft

Ground vehicles testing – low-speed (Subsonic)

Simulate real-world driving conditions to study aerodynamics on vehicles with the aim to reduce aerodynamic drag, increase efficiency, and lower CO2 emissions.

Study the acoustics of vehicles to reduce the aerodynamic noise, outside as well as inside the vehicle.

External flow tunnels are used to study the external flow through the chassis, the wind braking force

Climatic tunnels are used to evaluate engine colling, inside comfort level, the performance of door systems, braking systems, etc., under various climatic conditions.

Aircraft testing – low-speed and high-speed

Low-speed aircraft wind tunnel testing to measure the aerodynamic characteristics of aircraft - lift and drag properties, as well as stability of aircraft and engine components. These wind tunnel tests are used for static stability testing and pressure measurement.

The aerodynamic characteristics of aircraft at speeds of takeoff and landing etc.

Shock waves for high-speed aircraft are visualized using water as a working fluid.

Understanding the aeroacoustics by exploring aerodynamic noise, i.e., turbulent fluid motion, and acoustic pressure fluctuations, i.e., external noise generation via aerodynamic forces interacting with surfaces.

Water spray systems are applied for icing testing.

Spacecraft testing – high-speed (Supersonic, Hypersonic, Hypervelocity)

Atmospheric entry wind tunnels or plasma wind tunnels characterize the aerodynamic behaviour and heating of materials and structures by entry simulation on space vehicles such as rockets, satellites, launch vehicles, and spacecraft.

Simulation of the desired burn-up during atmospheric reentry to estimate the risk of debris reaching the ground.

High-enthalpy wind tunnels for heating testing of thermal protection systems for re-entry vehicles.

Structural testing – low-speed (Subsonic)

Wind tunnel tests are used to predict the wind loads and responses of a structure, structural components, and cladding to a variety of wind conditions.

Wind engineering to measure the air velocity around or within, forces or pressures upon civil engineering structures as well as the wind-induced responses – especially on large, tall, or wind-sensitive structures such as skyscrapers and tall buildings, groups of buildings, long-span roofs, tunnels, bridges, offshore structures.

Wind tunnel tests for bridges to evaluate girders, pylons, and cables, are conducted on girders, pylons, and cables, separately or together. Wind Tunnel Tests are also conducted for guard rails, barriers, or road signs, respectively.

Climatic wind tunnels to study the combined effects of wind and other climatic parameters such as rain, sand, sun, snow, or temperature on building elements

Data acquisition and sensors

Wind tunnels are used by engineers to test forces against wind pressure. Making precise measurements of pressures and forces on the test model allows the engineer to predict them on the full-scale aircraft and improve its aerodynamic performance.

In order to perform these measurements, engineers must use sensors and signal conditioning equipment in order to store and analyze the data. In other words, modern data acquisition systems are needed.

Wind tunnel sensors

For wind tunnel testing engineers usually use dynamic sensors such as:

Pressure sensors

Microphones

Force sensors

Strain gauges

Wind tunnel sensors are organized by speed classification. From subsonic use of condenser microphones for acoustic holography to shock sensors for studying boundary layer transition of hypersonic re-entry vehicles. Sensors are usually installed inside the wind tunnels or close to the model itself.

Signal conditioning

Signal conditioning is an electronic circuit that manipulates a signal in a way that prepares it for the next stage of processing. Many applications involve environmental or mechanical measurements from sensors, such as temperature and vibration. These sensors require signal conditioning before a data acquisition device can effectively and accurately measure the signal.

Once the signal is correctly conditioned it is ready to be stored by the data acquisition system and prepared for analysis using signal processing software.

References

What Are Wind Tunnels? Part of the NASA Knows! (Grades 5-8) series, June 25, 2014

A century of wind tunnels since the Eiffel. Bruno Chanetz, The French Aerospace Lab ONERA. Comptes Rendus Mecanique 345(8). July 2017.

What Is Wind Tunnel Testing? Boom Supersonic. August 10, 2021.