SIRIUS® Modular

Modular Data Acquisition (DAQ) System

Dewesoft’s sound power measurement solution combines the best of both worlds: industry-standard sound power measurements with a familiar, intuitive interface and unmatched adaptability. Effortlessly rate and compare different noise sources precisely while monitoring multiple additional parameters in real-time.

Compliant with key sound power standards, including ISO 3741, ISO 3743, ISO 3744, ISO 3745, ISO 6395, and ISO 6396.

Dewesoft devices are compatible with nearly all microphones on the market. With TEDS support, setup is seamless—just plug and play.

If you need externally polarized microphones for long-term stability, high dynamic range, or temperature resistance, Dewesoft offers device with built-in amplifiers for direct connection, eliminating extra hardware.

Dewesoft supports all microphone setups, from single-microphone sequential measurements (ISO 3741, ISO 3743) to multi-microphone fixed arrays (ISO 3744, ISO 3745) and complex hemisphere or cubic arrays (ISO 3745). Additional configurations include parallel plane arrangements for large machinery (ISO 639x) and rotating boom setups for averaging sound levels in challenging environments.

A smaller set of microphones can be used to cover all required positions by roving them across multiple locations. The measurements from each position are automatically merged, ensuring accurate calculation of the total enclosed sound power.

DewesoftX sound power module offers a simple and streamlined measurement process with a clear, intuitive interface that guides users every step of the way.

All calculated parameters are available both during measurement and offline. The software enables fast calculation of correction factors, including K1 (background noise), K2 (room correction), and C1, C2, and C3 (meteorological corrections for temperature and barometric pressure). It also supports raw time-domain data storage and offline sound power calculations.

Dewesoft provides optimized measurement procedures specifically designed for heavy machinery. It ensures accurate and reliable sound power analysis, even in demanding industrial environments. These procedures account for high noise levels and variable operating conditions, providing precise results tailored to heavy-duty applications.

Once the measurement is complete, effortlessly present your data using a pre-defined yet customizable report template. Tailor the layout, include key insights, and generate professional reports that meet industry standards with just a few clicks.

Every Dewesoft data acquisition system is bundled with award-winning DewesoftX data acquisition software. The software is easy to use but very rich and deep in functionality. All software updates are free forever with no hidden licensing or yearly maintenance fees.

Enjoy our industry-leading 7-year warranty. Our data acquisition systems are made in Europe, utilizing only the highest build quality standards. We offer free and customer-focused technical support. Your investment into the Dewesoft solutions is protected for years ahead.

And we're confident you'll love it too! But don't just take our word for it. Get hands-on with a demo unit, completely free of charge. No strings attached, just real data. Reach out to your local Dewesoft team and get your demo unit now!

It includes everything you need for advanced data acquisition and common signal processing — no maintenance fees, no contracts. You buy it, you own it. All future updates? Free forever. And the best part? Analysis seats are unlimited and free. Once the data is recorded, anyone can download our software to review and analyze your data — no license needed.

Dewesoft is 100% owned by employees who believe in what we do — and love doing it. We’re in this with heart, passion, and long-term commitment. What does that mean for you? Our core value — caring for our customers — isn’t going anywhere. We’re here for the next 100 years, protected from outside acquisitions. Your investment in our technology is safe, supported, and future-proof.

At Dewesoft, quality isn't just a promise — it's a core value. Our products are 100% designed, developed, and manufactured in-house, right in the heart of the European Union. From precision machining and PCB manufacturing to final assembly and software development — we do it all ourselves, to the highest ISO standards. We're proud to support local production and take social responsibility seriously.

At Dewesoft, quality is more than just a word — it's a commitment. That's why our products come with an industry-leading 7-year warranty. It's just one more way we protect your investment and give you peace of mind for the long run.

Sound power is the total acoustic energy emitted by a noise source, independent of distance or environmental factors. Unlike sound pressure, which varies based on location, sound power provides a consistent and comparable measure of a source’s noise emissions. This makes it essential for evaluating machinery, equipment, and industrial processes in compliance with noise regulations and industry standards.

Accurate sound power measurement helps manufacturers design quieter products, assess environmental impact, and ensure workplace safety. By following standardized procedures, engineers can reliably compare different noise sources and make informed decisions to reduce noise pollution and improve product performance.

Dewesoft provides a comprehensive sound power measurement solution for accurate and reliable noise assessment. Our solution follows industry standards, ensuring precise and repeatable measurements. These standards define key parameters such as noise types, test environments, measurement uncertainty, background noise criteria, air temperature and humidity conditions, instrumentation requirements, and microphone positioning. With Dewesoft, you get a seamless, standardized approach to sound power analysis.

Dewesoft’s sound power measurement solution complies with key international standards, ensuring accurate and reliable noise assessments:

ISO 3741 / ISO 3743 – Defines precision- and engineering methods for determining a noise source’s sound power level based on sound pressure measurements in a reverberation test room.

ISO 3744 / ISO 6395 / ISO 6396 – Specifies methods for measuring sound power or sound energy levels using sound pressure data from an enveloping measurement surface around the noise source.

ISO 3745 – Covers various techniques for determining sound power and energy levels of noise sources, including machinery, equipment, and their sub-assemblies.

With full compliance to these standards, Dewesoft ensures precise, repeatable, and standardized sound power measurements.

Sound power measurement is essential across various industries where noise control, regulatory compliance, and product optimization are critical. By providing a standardized and repeatable way to assess noise emissions, sound power analysis helps manufacturers and engineers improve product design, ensure workplace safety, and meet environmental noise regulations.

Industrial Machinery & Heavy Equipment

Noise assessment for excavators, backhoe loaders, bulldozers, and other earth-moving machinery (ISO 639x).

Compliance testing for factory and industrial equipment to meet workplace noise regulations.

Transportation

Evaluating vehicle component noise emissions, including powertrains, auxiliary components (alternators, starter motors, compressors, solenoids), drivetrains, etc.

Assessing aircraft components for regulatory compliance and passenger comfort, such as HVAC systems or their sub-components.

Consumer Electronics & Appliances

Testing household appliances (e.g., vacuum cleaners, washing machines, dishwashers, refrigerators, air conditioners) to meet ISO 3744 and other industry standards.

Sound power analysis for power tools and office equipment (printers, fans, copiers) to optimize performance and reduce noise pollution.

Energy & Power Generation

Noise measurements of power generators, industrial fans, and energy storage solutions.

Compliance testing for HVAC systems and large-scale cooling equipment.

Construction & Building Acoustics

Assessing sound power levels of construction machinery to minimize environmental noise impact.

Evaluating noise emissions from subcomponents of ventilation systems, elevators, and building equipment.

Dewesoft’s flexible sound power measurement solution supports any industry and measurement setup, from single-microphone tests to multi-mic hemispherical or cubical arrays, ensuring precise and repeatable results in any application.

Sound power measurements follow standardized microphone configurations based on the measurement environment, accuracy requirements, and test object size. The number and placement of microphones depend on the selected standard (e.g. ISO 3744 and ISO 6395) and the test conditions.

Typical Configurations by Standard:

Single Microphone with Sequential Measurements: A single microphone is used and moved between predefined positions. This setup is typical in controlled environments like reverberation rooms (ISO 3741 and ISO 3743).

Multi-Microphone Fixed Array: Multiple microphones are placed at fixed positions around the noise source. This setup is used for free-field and semi-reverberant environments (ISO 3744, ISO 3745).

Hemisphere or Cubic Microphone Arrays: 4, 6, 10, or more microphones arranged in a hemisphere or cube around the source. This microphone setup is used in free-field conditions or anechoic chambers (ISO 3745).

Parallel Plane Microphone Arrangement: A set of microphones positioned on a defined measurement surface, such as a hemisphere or a rectangular grid. This setup is suitable for large machinery and industrial applications (ISO 639x for heavy equipment).

Rotating Boom Microphone Setup: A microphone moves along a defined path using a rotating boom to average sound levels over time. Often used for large noise sources in non-ideal environments.

Dewesoft supports flexible microphone configurations, allowing users to adapt the setup based on their specific measurement needs while ensuring compliance with international standards.

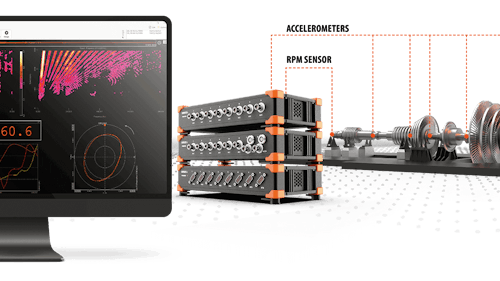

Dewesoft’s data acquisition (DAQ) systems offer unmatched flexibility for sound power measurements, with high-dynamic inputs and a scalable channel count, ranging from a single microphone to tens of channels. Whether you need a simple single-mic setup or a multi-microphone dome configuration with 10+ microphones, our hardware adapts to any measurement requirement.

Designed for precision and reliability, Dewesoft DAQ systems provide high dynamic range, low noise performance, and real-time data processing. With TEDS support for plug-and-play microphone recognition and seamless integration with our sound power module, setup is quick and intuitive. No matter the complexity of your test environment, Dewesoft ensures accurate, standardized, and efficient sound power analysis.

Bundled with our award-winning data acquisition software, which includes lifetime updates, it enables faster workflows, reduces costs, and ensures a remarkably quick learning curve.

Dewesoft’s sound power measurement system works seamlessly with microphones from any manufacturer, such as PCB, GRAS, or B&K. Microphones connect directly to our data acquisition systems.

If you prefer to use externally polarized microphones, due to demand for long-term time stability, higher dynamic range and/or high-temperature stability, Dewesoft also provides a SIRIUS-MIC200 device with integrated amplifiers for direct connection. This eliminates the need for any additional external hardware. SIRIUS-MIC200 amplifiers offer high dynamic capabilities (-160 dB), high acquisition rate (200 kS/s), multi-brand microphone support, TEDS support (Class 2), and preamplifier excitation (± 14 V),

Our acquisition systems fully support the TEDS standard, enabling plug-and-play functionality for TEDS-equipped microphones. For non-TEDS microphones, the setup remains simple and intuitive with a straightforward channel configuration process.

To make setup faster and easier for engineers, we’ve improved the microphone configuration visuals in our sound power measurement module. The updated graphics clearly indicate all microphone arrangements as defined in relevant standards, such as ISO 3744 and ISO 6395.

For example, the UI now visually represents the ISO 3744 hemisphere configuration, supporting 10 or 20 microphones, in accordance with Table B.2 of the standard. These enhancements ensure a more intuitive setup process, reducing errors and improving workflow efficiency—just another way Dewesoft simplifies sound power measurements.

DewesoftX software provides a simple, guided workflow for sound power measurement, ensuring accuracy and efficiency at every step.

Background Noise Measurement – Begin by recording the ambient noise level with the sound source turned off.

Sound Power Measurement – Turn on the sound source and measure its sound power level.

Multi-Sensor or Multi-Run Testing – If using sensor grouping or multiple test runs, repeat the process for each group to ensure comprehensive data collection.

With an intuitive interface and automated guidance, DewesoftX simplifies the entire measurement process, delivering precise and repeatable results.

Automate your sound power measurements with remote control channels for seamless start and stop triggering.

For example, light barriers can serve as trigger channels, automatically initiating measurements when a machine enters the test area. You can configure a single trigger channel or multiple channels for greater flexibility, ensuring precise and efficient data collection without manual intervention.

To ensure accurate sound power measurements, correction factors compensate for background noise, room influence, and meteorological conditions. DewesoftX automatically applies these corrections, delivering precise and reliable results.

K1 – Background Noise Correction

Adjusts for ambient noise interference.

Measured before switching on the sound source.

Now supports export and import of K1 data for seamless transfer across measurements.

We are also supporting averaged K1 results over multiple background noise runs.

K2 – Room Influence Correction

Compensates for sound reflections or absorption in the test environment.

Applied to the energy-averaged sound pressure levels across all microphone positions.

Now allows export and import of K2 data for improved workflow efficiency.

Users can define tolerance intervals for K2 reference sound source measurements to ensure compliance with standards.

C1 & C2 – Meteorological Corrections

Applied when air temperature is below 23°C or altitude exceeds 500 meters.

Ensures measurement accuracy in varying environmental conditions.

With these enhancements, DewesoftX simplifies correction factor management, making sound power analysis more flexible, accurate, and efficient.

While most sound power measurements rely on ⅓-octave band analysis (CPB), certain applications benefit from a more detailed frequency resolution. Narrowband FFT analysis allows engineers to detect specific patterns and peaks in the sound power spectrum, providing deeper insight into noise characteristics.

With Dewesoft’s sound power module, CPB and FFT analyses run in parallel, ensuring comprehensive spectral analysis without additional steps. Narrowband analysis can be easily enabled in the Spectral Band Settings, offering enhanced flexibility for advanced noise diagnostics.

The sound power module now supports result recalculation across multiple run cycles, improving accuracy and ensuring compliance with industry standards.

Multiple run cycle measurements help refine sound power results by averaging variations, and in some cases, they are mandatory according to certain standards. For example, ISO 6395—the standard for earth-moving machinery, including backhoe loaders—requires multiple run cycles for precise sound power determination.

| Run cycle | Description |

|---|---|

| K2 | Forward travel mode 2 |

| K1 run 1 | Reverse travel mode 2 |

| K1 run 2 | Stationary work cycle mode 2 |

| K1 run 3 | Backhoe work cycle mode 2 |

| Forward travel mode 1 | Forward travel mode 3 |

| Stationary work cycle mode 1 | Stationary work cycle mode 3 |

| Backhoe work cycle mode 1 | Backhoe work cycle mode 3 |

With this enhancement, Dewesoft makes it easy to configure and recalculate multi-cycle measurements, ensuring more reliable and standardized sound power analysis.

Dewesoft now also offers order-tracked sound power analysis through a dedicated module: Order Analysis Sound Power (OASP).

This new module, located under the Acoustics section in the application module list, enables advanced noise source identification in rotating machinery.

To add Order Analysis Sound Power, simply select More+ under the Acoustics category.

With order-tracked sound power, you can analyze the rotational order content of sound power emissions, allowing precise evaluation of individual rotating components. This helps identify which components contribute most to noise levels and may require modifications to meet sound power level criteria.

In addition to traditional sound pressure methods, sound power can also be measured using the sound intensity method, offering distinct advantages in various applications. Sound intensity measures both the magnitude and direction of acoustic energy flow, allowing for a more flexible and accurate assessment of noise emissions.

Advantages of the Sound Intensity Method:

Works in Any Environment – Unlike sound pressure methods, which require controlled conditions, sound intensity measurements can be performed in real-world environments, even in the presence of background noise and reflections.

Identifies Noise Sources – The directional nature of sound intensity helps pinpoint specific noise-emitting components, making it ideal for troubleshooting and optimizing product design.

Enables In-Situ Measurements – Measurements can be conducted directly on-site, without the need for large anechoic or reverberation chambers.

By leveraging the sound intensity method, engineers gain a powerful alternative for measuring sound power, improving noise diagnostics, product optimization, and regulatory compliance.

For more detailed information, please check:

Once the sound power measurement is complete, effortlessly export the data into a pre-designed Excel report template for automatic report generation.

The template is fully customizable, allowing you to add your company logo, measurement details, operator information, date, location, and more. This ensures professional, standardized reports tailored to your specific requirements.

You can find more about Dewesoft sound power measurement analysis by visiting the following links:

Sound Power Measurement Online PRO Training Course

Sound Power Webinar

Sound Level Meter Online PRO Training Course

Sound Pressure Measurement Online PRO Training Course

Sound Intensity Webinar

We've gathered all the answers you're looking for, neatly organized just for you.

Sound power is the characteristic of a sound source, it is independent of the distance and, therefore, a practical way of comparing various sound sources. Sound power can be measured in different ways (by sound pressure or by sound intensity).

Sound power or acoustic power is the rate at which sound energy is emitted, reflected, transmitted or received, per unit of time. It is defined as "through a surface, the product of the sound pressure, and the component of the particle velocity, at a point on the surface in the direction normal to the surface, integrated over that surface.

See the Dewesoft sound power solution.

The SI unit of sound power is the watt (W). It relates to the power of the sound force on a surface enclosing a sound source, in air. For a sound source, unlike sound pressure, sound power is neither room-dependent nor distance-dependent.

See the Dewesoft sound power solution.

Sound pressure or acoustic pressure is the local pressure deviation from the ambient (average, or equilibrium) atmospheric pressure, caused by a sound wave. In the air, the sound pressure can be measured using a microphone, and in water with a hydrophone. The SI unit for sound pressure p is the pascal (symbol: Pa).

Sound pressure is a property of the field at a point in space, while sound power is a property of a sound source, equal to the total power emitted by that source in all directions. Sound power passing through an area is sometimes called sound flux or acoustic flux through that area.

See the Dewesoft sound power solution.

Sound pressure level (SPL) or sound level is a logarithmic measure of the effective sound pressure of a sound relative to a reference value. It is measured in decibels (dB) above a standard reference level.

The standard reference sound pressure in the air or other gases is 20 µPa, which is usually considered the threshold of human hearing (at 1 kHz). The following equation shows us how to calculate the Sound Pressure level (Lp) in decibels [dB] from sound pressure (p) in Pascal [Pa].

See the Dewesoft sound power and sound pressure solution.

Sound intensity, also known as acoustic intensity, is defined as the power carried by sound waves per unit area in a direction perpendicular to that area. The SI unit of intensity, which includes sound intensity, is the watt per square meter.

Dewesoft sound power solution is fully compliant with the following sound power standards: ISO 3741, ISO 3743-1, ISO 3743-2, ISO 3744, ISO 3745, ISO 639-3, ISO 639-4, ISO 639-5, ISO 639-6.

Can't find the answer you're looking for? Our team is happy to answer your questions.

See and browse related and compatible data acquisition products.

Modular Data Acquisition (DAQ) System

High-Speed Data Acquisition (DAQ) System

Portable Data Acquisition (DAQ) Systems

Award-Winning Data Acquisition and Digital Signal Processing Software

IEC/ANSI traceable calibration for the entire measurement chain

See and browse related and compatible testing solutions.

Class 1 Sound Level Meter for Sound and Noise Level Measurement

Sound intensity level solution fully compliant with ISO standards

Applied psychoacoustics and sound engineering

Octave band frequency analysis solution for sound and noise

Noise and vibration analysis for rotating and reciprocating machinery

Reverberation time (RT60 reverb) measurement solution