Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Improving Tractor Field Testing

February 12, 2025

This application note shows how Dewesoft products provide an effective solution for the multi-physics validation of farm tractors. The mobile measurement instruments and easy-to-setup software are used for online field monitoring and multi-physics data acquisition with more than 200 channels.

Introduction

The client, a large tractor manufacturer, is in the business of developing and producing farming machinery for markets across the globe. With a multitude of use conditions for their machines all over the world, the engineering department needs more accurate multi-physics data for real field conditions as related to life profile specifications, numerical simulations, and test bench input data.

To avoid multiple test campaigns, the client decided to simultaneously acquire multi-physics signals from over 200 channels using only one data acquisition system. If the tractor is far from the development plant, the client can access the machine for remote control and data transfer by GSM or Wifi connection.

Measurement setup

The architecture is based on rugged IP67 data acquisition modules such as SIRIUS waterproof and KRYPTON based on EtherCAT® protocol technology. This protocol allows us to use only one cable between data acquisition modules for data transfer, power supply, and clock synchronization.

The complete measurement setup also involves versatile DEWE-43A USB data acquisition systems. The EtherCAT® and USB data acquisition devices work together, are perfectly synchronized and connected to the SBOX fanless control/storing unit.

Data acquisition systems

| Dewesoft Modules | Function |

|---|---|

| KRYPTON 16xTH | Temperature |

| KRYPTON 6xSTG | Strain gauges and universal conditioning |

| SIRIUSiwe 6xSTG | High-speed strain gauges and universal conditioning |

| SIRIUSiwe 8xLV | High-speed voltage |

| DEWE-43A | Universal conditioning and CAN bus |

| SBOXfe with 10Hz GPS GNSS & Wifi receiver | Control unit and storing |

| EtherCAT® SYNC Junction | Clock synchronization |

Type of channels/sensors

| Type of channels | Applications |

|---|---|

| > 200 analog channels | Strain, hydraulic pressure, temperature, voltage, noise, and vibration… |

| CAN bus channels | Engine, transmission, gearbox parameters… |

| Counters | Tachometer, rpm measurement |

| Video | Webcam monitoring |

Wireless communication device

Any Windows-compatible GSM 4G modem with USB or ethernet port.

Software

| Software | Function |

|---|---|

| Dewesoft X | Data acquisition setup and post-processing |

| DSA dynamic signal analysis upgrade | Noise and vibration analysis |

| ODE online data export plugin | Export selective data online from a Dewesoft measurement in progress |

| Data Manager plugin | Copy and store Dewesoft files automatically on FTP server or local drive |

| Any windows sharing desktop software | For internet remote control/access to SBOX control unit |

| Big data search engine (optional) | Data search on request parameters |

Analysis

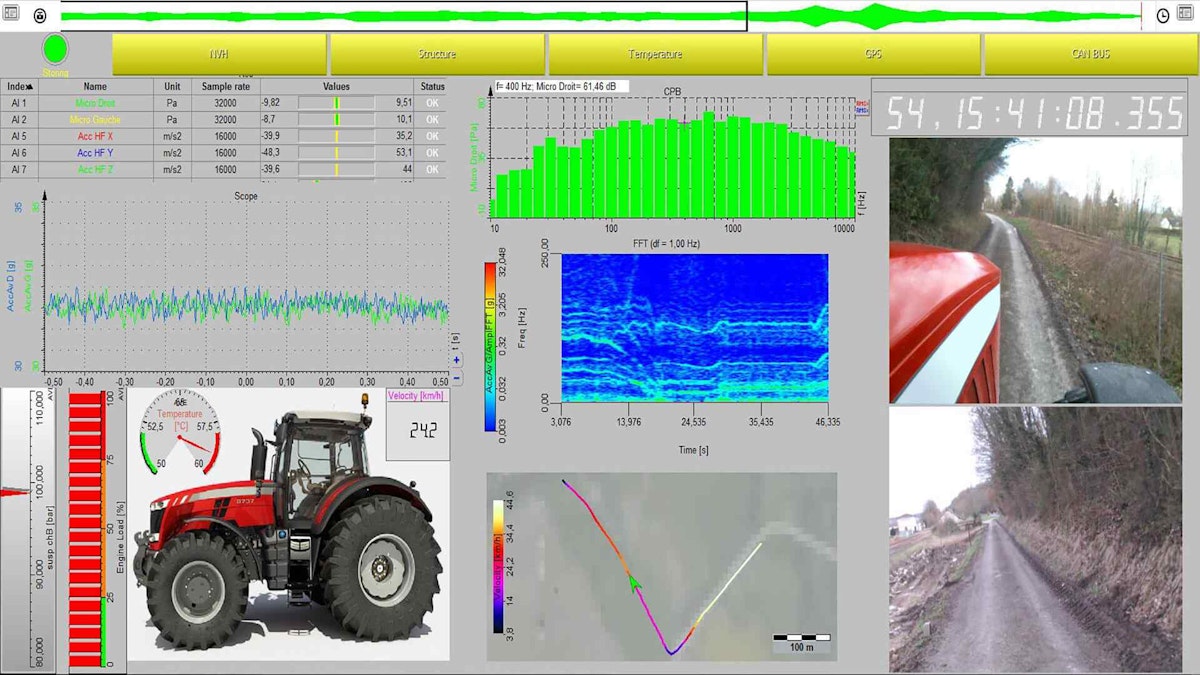

With simple GSM/internet connection, the user can access Dewesoft control units inside the vehicle for monitoring or selecting data to transfer. The measurement screen below is an example of Dewesoft X2 software capabilities to easily set up several different kinds of analysis representation: time signal, frequency spectrum, CAN bus parameters, level meter, GPS track (colored channels and map overlay) and video synchronization.

Key features:

Time data recording and post-processing (statistics, filters, maths functions…)

Extensive trigger features for the start/stop of the measurement

Export in multiple file formats or video, custom reports

Selective data transfer during acquisition

Simple access/remote control with desktop software

Data management

Conclusion

This off-road measurement configuration permitted the customer to combine different kinds of measurements with the same rugged data acquisition system. With various displays and calculations, the user was able to analyze multi-physics phenomena for any internal engineering clients or to export data in an appropriate file format for third-party post-processing software.

Based on the Windows platform, the Dewesoft control unit is able to communicate/interface with a common GSM 4G modem. With appropriate software solutions such as Dewesoft X and Windows software, data is sent from the machine to the customer control center over large distances. This allows the engineers in the control center to see real-time measurement values and video of the vehicle in real-time.