Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Teaching Practical Materials Science and Structural Dimensioning with Dewesoft

Anita Hurez and Denis Lokietek

BUT GMP, University Institute of Technology

December 9, 2025

The BUT GMP program at the University Institute of Technology (IUT) of Le Creusot trains students to become technicians who are ready for work in industry. They learn to manage the full life cycle of mechanical products, from design to production. The program builds skills in mechanical design, manufacturing methods, and production processes, with a focus on quality, safety, and maintenance. Hands-on exercises with Dewesoft equipment help students connect classroom theory with real structural testing and material research.

In the labs of IUT Le Creusot, engineering theory comes to life. Future mechanical qualified technicians don’t just study formulas. They measure, test, and prove them using Dewesoft technology. From beam bending to vibration testing, students gain real-world insight into how materials and structures behave under stress. They prepare them for the challenges of modern engineering.

The BUT GMP program at the University Institute of Technology (IUT) of Le Creusot trains industry generalists to manage the life cycle of an industrial product from design to industrialization.

Students develop expertise in mechanical design, methods, and manufacturing while integrating quality, safety, and maintenance considerations. Practical exercises using Dewesoft equipment enhance the program by connecting theory with real-world structural testing and material characterization.

The students perform the exercises when aiming for a University Bachelor of Technology (BUT) degree in Mechanical and Production Engineering.

The program allows graduates to:

Contribute to the competitiveness of companies at all stages of a product's life cycle by optimizing technical, scientific, economic, and human resources choices and integrating quality, maintenance, and safety requirements.

Work across various economic sectors, including transportation, robotics, agro-food, defense, and energy.

Collaborate with multiple stakeholders within the company.

The IUT of Le Creusot

The BUT GMP program trains senior technicians who are most often required to work in design offices, methods offices, and manufacturing in the mechanical industry. The core of their profession is mechanical design and manufacturing.

In materials science and structural dimensioning, we cover the different classes of materials, their mechanical behavior, and practical work on mechanical tests of traction, resilience, hardness, etc. Also, the dimensioning of structures, measurements of strains and displacements on structures or on bending beams, with comparisons between experimental measurements and numerical modeling.

The University Institute of Technology (IUT) of Le Creusot is attached to the Université Bourgogne Europe and resides on the South Burgundy Campus. It collaborates permanently with professional circles in a high-quality technical environment, offering innovative technological training adapted to economic activity.

A Bachelor of Technology is a national diploma at the BAC+3 level recognized at the European level. It is designed to facilitate direct professional integration and follows a work-study program format.

The Dewesoft measurement solution

The Dewesoft equipment enables us to measure deformations, displacements, and vibrations during the practical work of the 1st and 2nd years of the BUT Mechanical and Production Engineering (GMP) program. The BUT GMP program trains industry generalists to manage the life cycle of industrial products from design through industrialization.

Dewesoft provided the instrumentation suited for this task, data-acquisition hardware, and signal-processing software. We selected three different acquisition systems: Iolite, Krypton, and Sirius.

The modular industrial data acquisition (DAQ) system, IOLITE-1xACC, is ideal for this exercise, as we have only one IEPE sensor: the microphone. It is easy to connect to the PC, robust, and a good combination with DewesoftX.

We selected KRYPTON-3 STG, a 3-channel rugged EtherCAT data acquisition (DAQ) system for strain-gauge conditioning, because it is the perfect DAQ for strain gauges and rosettes, which we needed for exercises including beams with one to three strain gauges.

The modular SIRIUSi 8xSTG data acquisition (DAQ) system in the EDU version is ideal for crane exercises. It includes 4 strain gauge channels and one displacement sensor, and it can be easily upgraded later with more sensors if needed, for example by adding a load cell to verify the mass value.

Only five channels on the SIRIUSi were used for the current exercises, so another benefit is the option to add more channels for future measurements, expanding the number of sensors.

The DewesoftX data acquisition and digital signal processing software comes with all Dewesoft data-acquisition hardware at no additional cost and with free regular updates. This software for signal measurement, data recording, signal processing, and data visualization can cover numerous test and measurement applications across all markets.

First year - exercises in materials science

In the first year, the students will learn and gain from these two practical exercises:

Vibration Measurements to Evaluate the Young's Modulus of a Material

Strain Measurements on Beams made of sandwich (composite material) or metallic materials.

Vibration measurements to evaluate the Young's Modulus of a material

In this first-year practical exercise, students will explore how vibration measurements can reveal fundamental material properties. By striking a beam with a hammer and recording its response with Dewesoft data acquisition tools, they will determine the natural frequencies for different materials and boundary conditions.

From this, students will calculate the material’s Young’s modulus and gain firsthand experience linking experimental vibration data to basic structural stiffness and dynamic behavior.

A free-free beam, placed on a foam board, is subjected to a hammer impact. In response to this stress, the beam vibrates in different modes. The frequency measured for the first vibration mode can determine the material's stiffness.

We test different materials, including aluminum alloy, steel, polycarbonate, and copper. Students observe how geometric parameters, such as thickness and length, affect this frequency. The support conditions are also varied, free-free or clamped-free.

Hardware and Software Used

IOLITE-1xACC - modular industrial data acquisition (DAQ) system

DewesoftX - data acquisition and digital signal processing software

MicroTech Gefell M380 - Microphone

Learning outcomes

Students performing this first-year Materials Science exercise will gain a foundational understanding of how vibration analysis connects material properties to physical behavior.

By completing this exercise, students will be able to:

Relate vibration to material properties, connecting natural frequency to stiffness and density.

Perform experimental modal analysis using impact hammers and sensors to identify resonance frequencies.

Acquire and analyze vibration data with DEWESoft hardware (IOLITE) and software tools.

Understand how geometry and boundary conditions affect vibration modes.

Apply theory to practice by calculating Young’s modulus and validating experimental results against characteristics found in the literature.

Strain measurements on bending beams

In this first-year practical exercise, students learn to experimentally determine the bending stiffness of different beam materials using strain-gauge measurements. They gain hands-on experience instrumenting composite and metallic structures and acquiring and analyzing strain data using DewesoftX software.

Students deepen their understanding of the relationship between material properties, geometry, and structural performance by comparing measured and theoretical stiffness values.

By comparing a lightweight composite beam with heavier metal beams of similar stiffness, students explore the advantages of composite materials in engineering design, including improved strength-to-weight ratios and structural efficiency.

A sandwich cantilever beam, a composite consisting of two glass/epoxy skins and an aluminum honeycomb core, is subjected to bending. Using a strain gauge, strain measurement allows for determining the beam's bending stiffness. The students compare this value to the theoretical formula. This beam is then compared with two metal beams, one made of aluminum alloy and one of steel, both of similar stiffness but heavier.

Hardware and software used

Krypton-3 STG - 3-channel rugged EtherCAT data acquisition (DAQ) system for strain gauge conditioning

DewesoftX - data acquisition and digital signal processing software

Strain gauges

Learning outcomes

Students completing this first-year Materials Science exercise will be able to:

Measure and analyze strain in composite and metallic beams using strain gauges and DewesoftX software.

Relate material properties and geometry to bending stiffness.

Compare experimental and theoretical results to validate bending stiffness calculations.

Evaluate the advantages of composite materials over metals, such as strength-to-weight ratio and efficiency.

Apply practical insights to engineering design, including material selection.

Develop critical thinking by analyzing discrepancies between measured and theoretical values.

Second year – exercises in structural dimensioning

In the second year, the students will learn and gain from each of these two practical exercises:

Strain Measurements to Validate Beam Theory Results

Strain and Displacement Measurements on a Crane Model

Strain measurements to validate beam theory results

In this exercise, students deepen their understanding of solid mechanics by experimentally validating the fundamental principles of beam theory. They learn how to use strain gauges to measure local strains and relate them to bending stress and shear force.

Students calculate the Young’s modulus by applying successive loads and determine the Poisson’s ratio of the material from longitudinal and transverse strain readings. The activity builds competence in experimental setup, sensor calibration, data acquisition with Dewesoft, and the interpretation of real strain data in relation to theoretical predictions.

The students subject an aluminum cantilever beam to bending stress. Measuring the strain at three points on the beam determines the shear force. Measuring strain under successive loads determines the Young's modulus of the beam material. Longitudinal and transverse strain measurements determine the Poisson's ratio of the beam material.

Hardware and software used

Krypton-3 STG - 3-channel rugged EtherCAT data acquisition (DAQ) system for strain gauge conditioning

DewesoftX - data acquisition and digital signal processing software

Strain gauges

Learning outcomes

By completing this exercise, students will be able to:

Measure and analyze strain in beams to determine bending stress, shear force, and identify Young’s modulus and Poisson’s ratio.

Relate experimental data to beam theory and validate theoretical predictions with real measurements.

Calibrate and utilize sensors and DAQ systems (strain gauges, Krypton-3 STG, DewesoftX) to ensure accurate data acquisition.

Develop critical thinking by comparing experimental results with theoretical expectations.

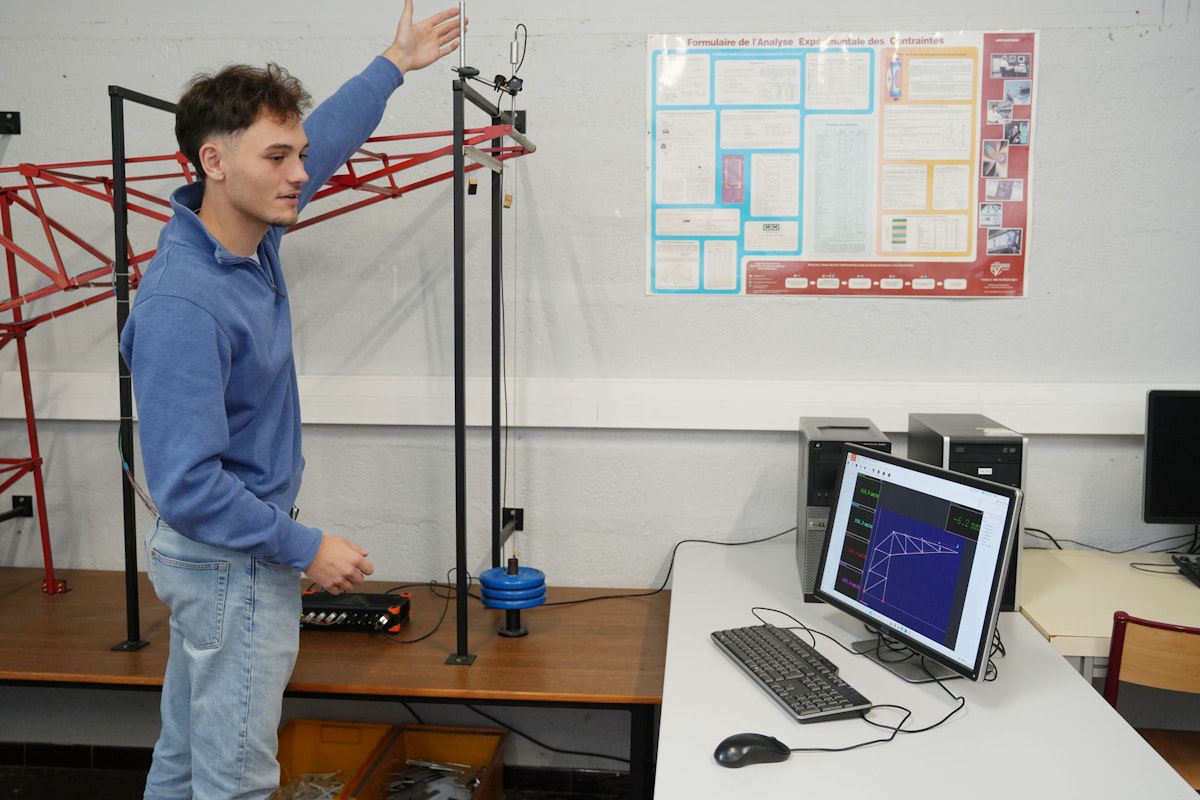

Strain and displacement measurements on a crane model

This experiment bridges numerical simulation and real-world testing. Students compare finite element analysis (FEA) predictions with experimental strain and displacement data collected from a physical crane model.

They learn to validate numerical models using strain gauges and displacement sensors, analyze measurement uncertainty, and assess the correlation between simulation and experiment.

The exercise reinforces the importance of experimental verification in structural design and develops practical skills in instrumentation and data analysis using Dewesoft tools.

This practical work compares the numerical results from a finite element calculation with measurements taken on the crane model. We have equipped the crane model with four strain gauges on the most stressed bars of this lattice structure. The maximum displacement is measured and compared to the numerical calculation results.

Hardware and software used

SIRIUSi 8xSTG - modular data acquisition (DAQ) system

DewesoftX - data acquisition and digital signal processing software

Displacement sensor

Strain gauges

Learning outcomes

By completing this exercise, students will be able to:

Measure strain and displacement on a structural model using strain gauges and displacement sensors.

Compare experimental data with FEA predictions to validate numerical models.

Analyze structural behavior, including load, stress, and deformation distributions.

Assess measurement uncertainty and interpret its impact on experimental results.

Integrate theory and practice by bridging simulation results with real-world measurements.

Conclusion

By performing these exercises, students link theoretical mechanics, material science, and structural analysis with practical measurement techniques. They develop the ability to validate numerical models, analyze real-world structural behavior, and make informed design decisions—key skills for mechanical engineering professionals.

The Dewesoft-equipped practical exercises at IUT Le Creusot provide students with a comprehensive learning experience that combines experimental measurement, numerical simulation, and theoretical analysis.

Graduates will develop critical skills in material characterization, structural testing, and model validation, preparing them to make informed engineering decisions across the product lifecycle. By bridging classroom theory with real-world applications, the program effectively cultivates competent, industry-ready engineers.