Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Using Optris Thermal Cameras with Dewesoft DAQ Systems for Synchronized Temperature Measurement

December 29, 2025

Overview: thermal imaging in modern data acquisition

Thermal imaging has become an essential tool in engineering, validation, and R&D. It enables you to capture real-time temperature changes that conventional sensors alone cannot detect.

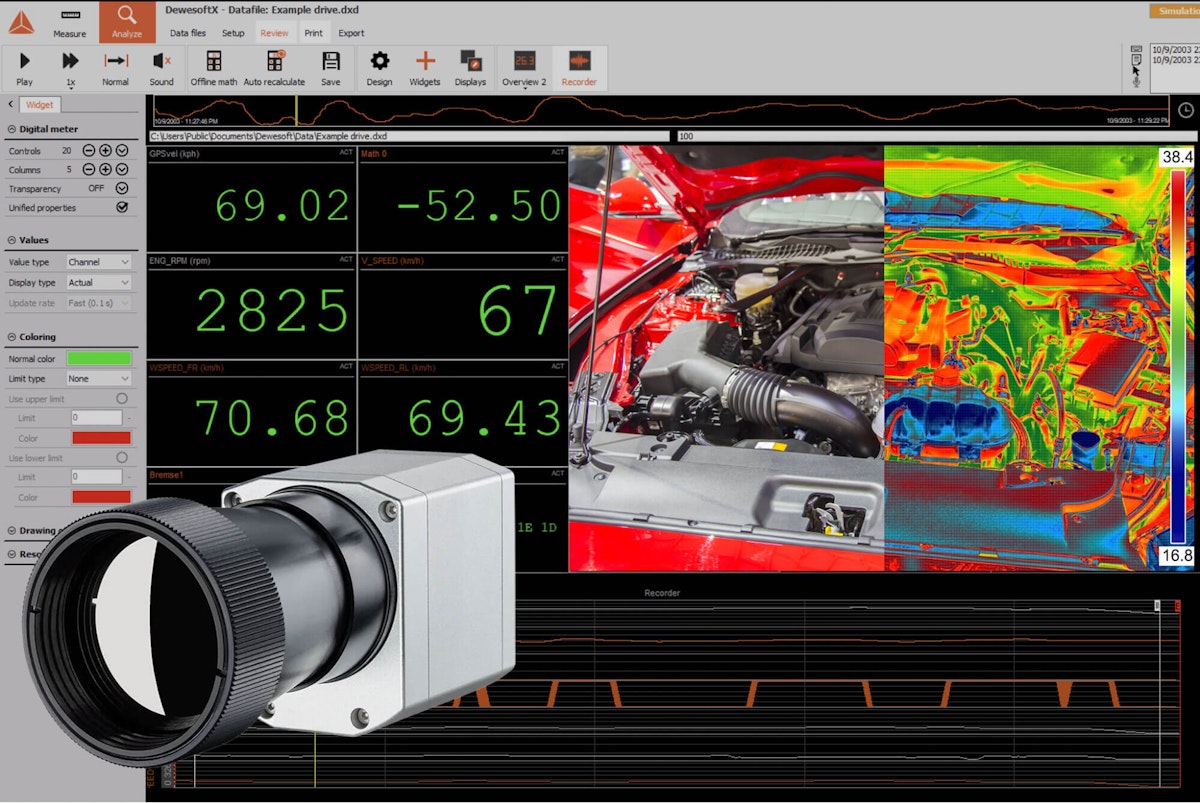

DewesoftX (DSX) data acquisition software integrates directly with Optris thermal cameras. It allows users to record thermal images and temperature channels synchronously with analog, digital, CAN, GPS, inertial, and other data sources.

This capability provides a complete, high-resolution thermal and mechanical picture of any test article, from automotive powertrains to electronics and high-energy components.

Compatible Optris cameras

DewesoftX supports the following Optris cameras through a dedicated plugin:

Optris PI series (PI 640, PI 400, PI 1M, PI 05M, PI 08M)

Optris Xi series (Xi 80, Xi 400)

Important: Only PI and Xi series devices with USB interfaces are compatible with the Dewesoft Optris plugin. Always verify compatibility before purchasing hardware.

Initial setup and software requirements

Install PIX connect

Download and install PIX Connect from the Optris website. This package includes essential drivers and SDK components needed for DewesoftX software communication. Full setup instructions are available in the Dewesoft manual.

NOTE: PIX Connect is not needed for live viewing once DewesoftX is set up. It’s only for initial configuration, firmware updates, and verification. Close PIX Connect completely before running DewesoftX, as they cannot access the camera simultaneously.

Installing the Optris plugin in DewesoftX

Download the Optris plugin found on Dewesoft’s plugin page, then follow these steps:

1. Open DewesoftX and navigate to Options → Settings → Extensions.

2. Enable the Optris Plugin from the extension list.

3. Connect your Optris thermal camera via USB; Windows will automatically install the driver.

4. Add the camera as a device under Settings.

Configuring Optris cameras in DewesoftX

Channel setup

After enabling the plugin, go to Channel Setup → Optris. Your connected camera will appear with full access to:

Temperature ranges supported by the model

Frame rate settings

Color palette selections (iron, rainbow, grayscale, and more)

Measured Areas, allowing average, minimum, and maximum temperature extraction

Camera resolution, calibration, and environmental parameters

Key parameters include:

Temperature Range: Defines calibrated measurement span (e.g., −20°C to 100°C or extended mode).

Emissivity & Transmissivity: Critical for accurate readings and must match the surface properties of the test object.

Ambient Temperature Adjustments: Overrides default values when environmental conditions vary.

The Storing section lets you define whether DSX stores raw thermal frames or processed numerical data and specifies the frame logging rate.

Auto-calibration and shutter (“flag”) control

The plugin controls the camera’s internal calibration shutter:

Auto mode ensures consistent, hands-off calibration.

Manual mode is helpful in time-critical tests when predictable shutter timing is required.

Calibration can be triggered via a DAQ trigger channel, with an adjustable trigger value and interval.

The bottom of the panel features a Focus slider for precise optical tuning.

Defining measured areas for temperature channels

Each Measured Area creates an independent temperature channel in DewesoftX. Users can define up to 25 areas (or more if needed) of varying shapes and sizes for detailed temperature mapping. DewesoftX then logs:

Minimum temperature

Maximum temperature

Average temperature

These thermal channels synchronize perfectly with other DAQ inputs.

Application example: BMW XM engine heating cycle

To demonstrate the integrated workflow, a thermal test was performed on the Dewesoft BMW XM demonstration vehicle.

Camera model: Optris Xi 400

The Xi 400 is ideal for fast-changing thermal events due to its high frame rate and robust resolution:

Resolution: 382 × 288

Frame Rate: Up to 80 Hz (depending on mode)

Lens Options: Multiple fields of view available

Test setup

Camera positioned 1–1.5 m in front of the engine bay.

The field of view was configured to capture the top block and intake.

Thermocouples placed throughout the engine bay and logged via KRYPTON 16xTH.

Synchronized with CAN bus data for coolant temperature and RPM.

The Optris camera was connected to the PC via USB.

Configuration in DewesoftX

Live preview enabled for focus and framing.

“Iron palette” was selected for clear visualization of heat distribution.

Measured Area defined over the top engine block.

Recording process

Logging began before ignition to capture the ambient baseline.

The engine was cycled through idle and several revs.

Observed temperature behaviors:

Manifold temperatures spike rapidly

The engine block warms gradually

Radiator heating lags, aligning with coolant flow dynamics

Post-processing

The thermal video and numerical temperature channels were synchronized with:

RPM

CAN coolant temperature

Thermocouple readings

Other vehicle sensors

This setup provided a complete thermal-mechanical profile of the engine heating cycle.

Tips for optimal thermal measurement accuracy

Focus carefully using the lens or software tools before recording.

Set emissivity correctly for the material (e.g., painted metal ~0.95, polished aluminum lower).

Avoid reflections from sunlight or shiny surfaces that distort temperature readings.

Synchronize everything: Dewesoft’s advantage is the ability to combine thermal, analog, digital, CAN, GPS, power, audio, and video signals in perfect time alignment.

Summary

Integrating Optris thermal cameras with DewesoftX provides a powerful thermal measurement workflow for automotive testing, electronics evaluation, environmental chambers, aerospace components, and other thermal-intensive applications. The Optris plugin enables:

Real-time thermal imaging

High-speed temperature channel extraction

Full synchronization with all other DAQ domains

In the BMW XM engine warm-up example, the Optris Xi 400 camera captured fast transient temperature changes that conventional sensors alone cannot visualize. The combination of thermal video, numerical temperature channels, CAN data, and thermocouples produced a comprehensive thermal model of the engine’s behavior.