Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

End-of-Line Testing: Ensuring Quality and Performance in Modern Manufacturing

January 5, 2026

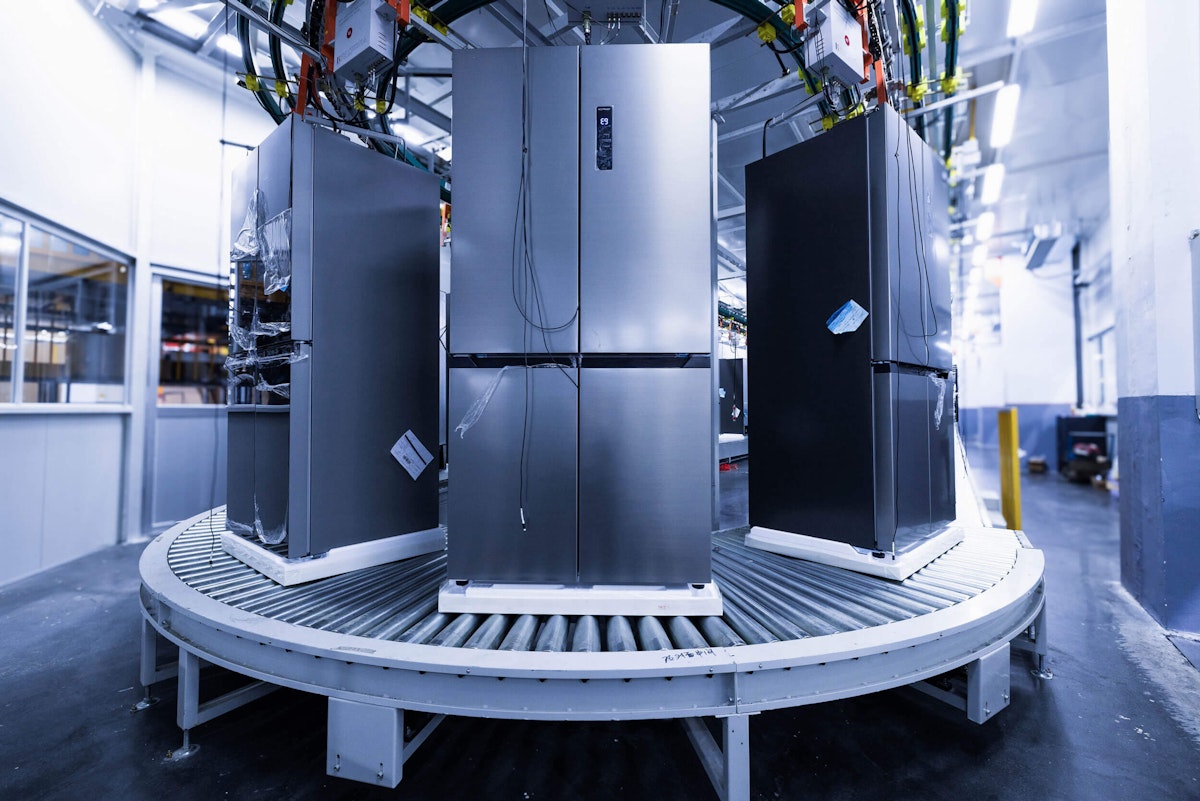

End-of-line (EOL) testing is the final quality assurance step in manufacturing, during which fully assembled products undergo comprehensive functional, thermal, electrical, mechanical, acoustics, and safety tests to verify compliance with all performance specifications before shipment.

End-of-line (EOL) testing is the final quality assurance step in manufacturing, during which fully assembled products undergo comprehensive functional, thermal, electrical, mechanical, acoustics, and safety tests to verify compliance with all performance specifications before shipment.

EOL is the moment of truth for manufacturers: the last opportunity to detect defects, functional deviations, or hidden issues that may have developed during assembly or component integration. By thoroughly verifying a product’s key attributes, EOL testing protects consumers, strengthens brand reputation, and safeguards against costly field failures or recalls.

Industries that follow Six Sigma principles or zero-defect philosophies, such as the Zero Acceptance Number Sampling Plan (c=0), employ EOL testing to ensure every unit meets performance and safety standards before shipment. Some producers take every 1000 samples for verification and build their statistics on them.

What is end-of-line testing?

End-of-line (EOL) testing is a comprehensive, data-driven process that verifies products perform correctly under real-world operating conditions. Using sensors, measurement systems, and automated test equipment, it evaluates mechanical, electrical, software, and functional performance while providing high-resolution data for consistent, traceable, and actionable quality insights.

EOL testing can be far more than a visual inspection. It is a comprehensive, data-driven process designed to replicate real-world operating conditions and confirm that the product performs exactly as intended. During testing, products are subjected to various simulated loads, environmental conditions, and functional challenges while sensors and measurement systems capture key performance metrics.

Depending on the product's complexity, EOL testing may include mechanical load and stress assessments, electrical load, final functional software or diagnostics steps, acoustic and vibration analysis, and digital communication interface checks. For some products, such as household appliances, the EOL testing process may be as straightforward as verifying that the system powers on and responds correctly. For others, such as automotive e-axles, high-performance traction batteries, smart speakers, or medical infusion pumps, the process can involve multi-step sequences, precise measurements, final parameter tuning, advanced data analytics (including ML/AI), and digital documentation (traceability).

Automation plays a central role in modern EOL testing. Automated Test Equipment (ATE) enables repeatable, consistent, and rapid test execution, eliminating the variability associated with manual inspection. ATE systems can execute complex test sequences, gather high-resolution data, and provide instant feedback on whether a unit meets all required parameters. This not only accelerates production but also improves traceability and data quality, offering engineers valuable insights for continuous process improvement.

Why end-of-line testing matters for quality and safety

EOL testing serves as the final quality safeguard in manufacturing, ensuring that every product leaving the production line meets reliability, safety, and performance expectations. Beyond simply identifying defects, modern EOL testing provides valuable insights for process optimization, regulatory compliance, and continuous improvement. Key benefits and capabilities of EOL testing include:

Reliability and safety assurance: Detects defects that may be missed during in-process testing, including intermittent wiring faults, chip or software errors, or calibration drift.

Customer satisfaction: Ensures products perform as intended, reducing the risk of field failures, recalls, and warranty claims.

Data collection and analysis: Captures production data to reveal recurring failure modes, highlight process inefficiencies, and inform design improvements.

Regulatory and warranty compliance: Archives test data for audits, regulatory reporting, warranty management, and long-term reliability studies.

Intelligent diagnostics: Measurement and data acquisition, machine learning (ML), and predictive data analytics enable root-cause identification and process optimization.

Industry 4.0 Readiness: Integrates OT systems (automation, control, and measurement) with IT platforms (ERP and data analytics) to enable automated, data-driven manufacturing and improve upstream processes and overall production efficiency.

The EOL testing process

While every product and industry has unique requirements, most end-of-line testing workflows follow a similar structure. A typical process includes the following steps.

Test planning and limit definition: The process starts with requirements. Engineering, quality, and production teams define which parameters must be verified, which measurements are required, and the pass/fail limits. Safety, regulatory, and customer requirements are mapped directly to test steps.

Fixture and test bench design: The next step is to design and build fixtures, test benches, and interfaces that connect the finished product to the test system. This includes mechanical clamping, electrical connectors, fluid or pneumatic interfaces, and safety guarding. At this stage, the data acquisition and control hardware is selected and integrated.

Product identification and configuration: Once the test station is in operation, every unit first passes through an identification step. Barcodes, QR codes, or RFID tags link the product to the correct test recipe and store key information such as serial number, variant, software version, and configuration.

Automated functional and safety tests: The core of EOL testing is an automated test sequence. The system powers the product, simulates normal and faulty operating conditions, measures responses, and checks that all functions and safety mechanisms work as intended. This can include electrical, mechanical, leak, performance, and software tests, depending on the product.

Measurement, data acquisition, and evaluation: During the test sequence, all relevant sensors and signals are measured and evaluated. The system compares measured values against predefined limits and rules. Failures are flagged immediately, often with clear diagnostics so operators can react quickly.

Result logging and traceability: After each test, the system records the pass/fail status, key measurement results, and the full data set, as required. These records are linked to the product’s unique ID and stored in a database, MES, or ERP system. This ensures full traceability throughout the product’s life cycle.

Feedback to production and engineering: EOL data is most valuable when it is not just archived, but actively used. Trends in failure rates, measurement drift, or process variation can highlight problems in production, supply quality, or design. Regular reviews with production and engineering teams help close the loop and continuously improve the process.

Common EOL test types

End-of-line test systems often combine multiple test types or attributes into a single automated sequence. The exact mix depends on the product, the risks, and the applicable standards, but the following categories are common.

Functional tests: Verify that the product performs its intended functions correctly. Examples include motors that start and run at the correct speed, valves that open and close on command, or electronic devices that respond correctly to user inputs.

Electrical safety and performance tests: Check that the product is electrically safe and correctly wired. Typical tests include hipot (high-potential) tests, insulation resistance, continuity, ground bond tests, leakage current measurements, and current or power consumption under load.

Leak and pressure tests: Ensure the integrity of systems that handle fluids or gases. Pressure decay, flow, and vacuum tests detect leaks in housings, seals, and connections. These tests are critical for applications such as cooling systems, brake systems, and sealed enclosures.

Performance tests under load: Measure key performance indicators under realistic operating conditions. Examples include torque and speed of rotating machinery, flow rates of pumps, temperature rise during operation, or power, efficiency, and noise of HVAC equipment.

Environmental and stress tests: Short, targeted stress tests can reveal early failures. These may include brief burn-in cycles at elevated temperature, vibration sequences, or thermal cycling. While full qualification tests are usually conducted earlier, EOL stress tests help screen out weak units.

Software and communication tests: Modern products rely heavily on embedded software and networks. EOL tests often verify firmware versions, configuration parameters, and communication over CAN, LIN, Ethernet, or other protocols. They may also simulate network nodes to check system behavior.

Visual and dimensional checks: Vision systems and sensors can verify correct assembly, label placement, color coding, and the presence of critical components. Dimensional checks confirm that interfaces and mounting features meet specified tolerances.

EOL versus in-line testing

End-of-line testing and in-line testing both contribute to product quality, but they serve different purposes and are used at various stages of the manufacturing process.

In-line testing

In-line tests are performed during the production process, often at intermediate stations. They typically focus on subassemblies or critical steps, such as checking a PCB before it is mounted into a housing, or verifying the torque of a bolted joint.

Characteristics of in-line testing:

Performed at multiple points along the line

Targets subassemblies or specific operations

Detects defects early, before further value is added

Often integrated tightly with the workstation tools

End-of-line testing

End-of-line tests are performed after final assembly, just before packaging and shipment. They view the product as a complete system and verify that all functions and safety features work correctly together under realistic conditions.

Characteristics of EOL testing:

Performed at the final stage of production

Tests the fully assembled, finished product

Acts as the last quality gate before shipment

Often implemented as a dedicated test cell with high test coverage

In practice, high-performing manufacturers use both:

In-line testing prevents defects from moving downstream and helps stabilize individual process steps.

End-of-line testing provides a final, system-level verification that gives both the manufacturer and the end customer confidence.

EOL testing in the automotive industry

In the automotive sector, end-of-line testing is essential for ensuring the performance, safety, and longevity of vehicles and their subsystems. Each vehicle that rolls off the assembly line must meet strict regulatory and customer requirements. To achieve this, automakers rely on highly automated EOL test benches that evaluate mechanical, electrical, and digital systems in an integrated manner.

A typical automotive EOL process includes:

e-Axle performance testing: Measurement of electric power, torque, speed, temperature, vibration, and noise as an acoustic signature.

Braking system tests: Hydraulic pressure tests and anti-lock braking (ABS) functionality checks ensure precise response under varying loads.

Electrical system testing: Wiring harnesses, control modules, and battery packs are checked for correct voltage levels, current draw, and insulation resistance.

ADAS validation and calibration: RADAR and camera systems are stimulated and tested together with the control software.

Noise, vibration, and harshness (NVH) testing: Evaluates driver comfort and interior noise, identifying unwanted vibrations, resonances, or noise sources.

Infotainment and connectivity checks: Confirms proper Bluetooth pairing, GPS navigation accuracy, and user interface functionality.

High-performance Battery testing for EVs and HEVs: Assesses electrical performance, insulation resistance, thermal behavior, cell balancing, and safety features under simulated operating conditions.

Automotive manufacturers rely heavily on data acquisition (DAQ) systems, such as those from Dewesoft, during these tests to collect synchronized data from many different sensors and signals. Real-time data visualization enables engineers to verify test results instantly and make data-backed decisions. By integrating EOL test data with manufacturing analytics platforms, automakers can track production trends, predict maintenance needs, and optimize assembly operations.

EOL testing in machine manufacturing

EOL testing in the machine manufacturing industry covers a broad range of equipment, including precision CNC machines and industrial robots, as well as agricultural, packaging, and medical devices. Each product type has unique performance criteria, but the goal remains the same: ensure the machine operates flawlessly before delivery to the customer.

In machine manufacturing, EOL testing typically includes:

Functional performance testing: Verifies that mechanical assemblies move smoothly, stay within design tolerances, and operate at commanded speeds.

Accuracy and repeatability testing: Ensures each movement or operation remains consistent over time, critical for precision applications such as semiconductor fabrication or robotic assembly.

Safety validation: Tests emergency stop functions, interlock systems, and protective guards to confirm compliance with safety standards.

Efficiency and power consumption measurements: Assess how effectively a machine converts energy into useful work, helping reduce operating costs and meet environmental regulations.

Software and control system validation: Confirms that PLCs, HMIs, and embedded software execute correctly, sensors respond as expected, and module communication remains stable under load.

Durability testing: Operates machines continuously or under exaggerated conditions to predict long-term performance and identify potential weaknesses before full production.

The diversity of this sector means that no single EOL test solution fits all applications. Test setups are frequently customized, with test parameters tailored to the product’s operational profile, critical components, and expected duty cycles.

How Dewesoft supports eEnd-of-line testing

End-of-line (EOL) testing relies on a sophisticated ecosystem of instruments, sensors, and software to measure, control, and validate performance across multiple physical domains. At the heart of any modern EOL test system lies the data acquisition (DAQ) system, which acts as the central nervous system of the test bench, collecting synchronized data from sensors measuring temperature, pressure, voltage, current, vibration, sound, strain, and more.

Dewesoft DAQ and control instruments for EOL testing

High-performance DAQ and control systems: Includes IOLITE©, OBSIDIAN©, and SIRIUS© RT, designed for automated EOL testing in automotive, machinery, and electronics manufacturing.

Real-time control capabilities: Enable engineers to drive servos, actuators, and other test devices while capturing precise measurement data.

Dual EtherCAT© buses:

Primary bus: records high-resolution data to a PC.

Secondary bus: provides low-latency real-time control for integration with platforms such as Clemessy Syclone, Beckhoff TwinCAT©, MTS FlexTest©, Acontis© EC_Master, and NI LabVIEW©.

Simultaneous multi-domain measurement: Captures electrical, mechanical, and acoustic parameters to correlate data across subsystems and detect subtle interactions or potential failure modes.

Sensors and transducers: Includes accelerometers, strain gauges, pressure transducers, thermocouples, RTDs, microphones, and load cells for precise physical measurements.

Programmable power supplies and electronic loads: Simulate real-world electrical conditions to test performance under various scenarios.

Complementary instruments: Oscilloscopes, multimeters, and communication interface testers ensure timing accuracy, signal integrity, and protocol compliance.

Vision systems: Automate inspection, confirm component placement, and enhance overall test accuracy.

By combining precision measurement, real-time control, automation, and advanced analytics, Dewesoft DAQ systems enable engineers to perform functional testing, environmental simulation, NVH analysis, and safety verification with speed and accuracy. Real-time visualization, automated pass/fail evaluation, and comprehensive data logging enable immediate defect detection, traceability for quality assurance, and optimization of test sequences. Integrated into high-volume production lines, Dewesoft instruments support robotic handling, fixture control, and automated measurement, helping manufacturers increase throughput, reduce test time, and ensure consistent product quality—making them a cornerstone of intelligent, Industry 4.0-ready EOL test systems.

Learn more:

Automation and data in EOL testing

Automation has revolutionized end-of-line testing. Fully automated EOL cells can run around the clock with minimal human intervention, executing complex test sequences in a fraction of the time once required. Robots handle mechanical actions, while the test software controls signal routing, triggers measurement acquisition, and evaluates data against predefined acceptance criteria.

The integration of machine learning and analytics adds another layer of intelligence. By continuously analyzing test data, modern EOL systems can identify trends, estimate failure probabilities, and dynamically adjust test parameters to improve throughput and accuracy. This aligns with Industry 4.0 principles, where connectivity, data sharing, and smart analytics drive quality improvements across the entire production lifecycle.

In addition to automation and analytics, modern EOL systems provide full traceability by capturing detailed measurement data, test results, and calibration records for every unit. This data can be seamlessly integrated with Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) platforms, linking test outcomes to production orders, serial numbers, and quality metrics. Such integration enables manufacturers to track defects, generate regulatory reports, manage warranty claims, and analyze production trends across shifts, lines, or plants, ensuring that every product leaving the factory is fully documented and compliant with industry standards.

Key KPIs and best practices for EOL testing

Conforming end-of-line (EOL) testing to recognized industry standards ensures that products meet safety, reliability, and performance requirements while facilitating market acceptance and regulatory compliance. Standards such as ISO 9001 for quality management, ISO 13485 for medical devices, IEC 61010 for electrical safety, and automotive-specific norms like ISO 26262 for functional safety provide clear guidelines for designing test protocols, acceptance criteria, and traceability procedures. Aligning EOL workflows with these standards supports consistent measurement practices, reliable documentation, and repeatable test sequences, enhancing both product quality and operational efficiency.

Common key performance indicators (KPIs) used to manage and optimize EOL testing include:

First-pass yield (FPY): the percentage of units that pass all tests on the first attempt.

Rework and scrap rate: the share of units requiring repair or being discarded.

Test cycle time: the duration each unit spends in the EOL cell.

Test coverage: the extent to which safety and performance requirements are evaluated.

Defects per million opportunities (DPMO): used in Six Sigma programs.

Best practices

Design tests from requirements and risk: Start from product requirements and formal risk analysis. Every critical function and hazard should map to at least one test, with clear limits and conditions.

Align EOL strategy with quality targets: Decide whether 100 percent testing or sampling is appropriate based on risk, regulations, and customer expectations. Safety-critical products usually require full coverage.

Keep test systems modular and scalable: Use modular fixtures, software, and DAQ or control hardware so the system can be adapted to new product variants and changing test requirements without major redesign.

Integrate with MES, ERP, and quality systems: Connect EOL results with higher-level systems to enable full traceability, automated reporting, and data-driven improvement.

Use data for continuous improvement: Regularly review EOL data for trends in failures, margins, and timing. Involve cross-functional teams to identify root causes and implement corrective actions in design, sourcing, or process steps.

Plan maintenance and calibration: Treat the test system itself as a critical asset. Schedule sensor and instrument calibration, and maintain fixtures and interfaces to avoid false failures and downtime.

By combining adherence to industry standards with robust KPIs, modular test design, and integrated analytics, manufacturers can optimize throughput, ensure regulatory compliance, and deliver consistently high-quality products. Dewesoft is not just a hardware provider but a partner in quality engineering, enabling data-driven EOL testing that supports traceability, operational efficiency, and continuous improvement.

Example: end-of-line testing for an electric motor

The following example illustrates what an end-of-line test cell looks like in practice.

An electric motor manufacturer assembles motors for automotive or industrial applications. At the end of the production line, each motor enters an automated EOL test stand, where:

The motor’s barcode is scanned, and the test system loads the correct test protocol based on motor type and options.

The motor is clamped into a fixture and connected to electric power (often 800 V), and a shaft with a torque flange (including rotational speed). Vibration, noise, and temperature sensors are automatically positioned and connected to the DAQ system.

The test sequence runs automatically. The controller drives the motor through the Motor Control Unit (MCU) via a digital communication bus (CAN FD, CAN, Automotive Ethernet, …) to different speed and load or performance points (Nm), while the data acquisition system measures all physical quantities.

Next to the multi-physics measurement, the system performs insulation resistance and hipot tests to verify electrical safety, followed by a short run-in at elevated load to detect early failures.

All measurements are compared against specified limits in real time. If any parameter is out of range, the motor is marked as failed, and diagnostics are logged for the operator.

For passing units, the system records key parameters and stores them, along with the serial number, in the plant database and the MES. This provides complete traceability for warranty and customer support.

A similar approach can be applied to many other products, including pumps, gearboxes, actuators, and complete assemblies.

Conclusion

End-of-line testing is the final, indispensable step in manufacturing that bridges the gap between production and customer delivery. It ensures that every product—whether a car, a medical device, or an industrial machine—functions precisely as designed. By combining advanced data acquisition, sensor technologies, automation, and analytics, EOL testing not only validates product quality but also drives innovation and continuous improvement in manufacturing processes.

As manufacturing becomes increasingly digital and connected, the importance of accurate, automated EOL testing will only grow. Companies that invest in sophisticated test systems today—leveraging synchronized data acquisition, integrated analytics, and adaptive automation—will gain a decisive advantage in product reliability, customer trust, and overall operational excellence.

Frequently asked questions about end-of-line testing

Q1: What is End-of-Line (EOL) testing?

A1: EOL testing is the final quality check in the manufacturing process. It involves a series of comprehensive tests on fully assembled products to ensure their functionality, performance, and adherence to design specifications before they reach the customer.

Q2: Why is EOL testing necessary?

A2: EOL testing is crucial for detecting defects, malfunctions, or deviations from quality standards that may have occurred during production. This ensures that only high-quality, reliable products are released to the market, preventing costly recalls and protecting brand reputation.

Q3: What types of tests are typically performed during EOL testing?

A3: EOL testing can include a wide range of tests, such as electrical tests, mechanical stress tests, acoustic measurements, vibration analysis, software validation, and communication protocol checks. The specific tests depend on the product's characteristics.

Q4: How does automation contribute to EOL testing?

A4: Automated Test Equipment (ATE) is often used in EOL testing to ensure consistency, speed, and accuracy. ATE systems can rapidly execute complex test sequences, collect large amounts of data, and provide immediate feedback, improving efficiency and reducing human error.

Q5: Which industries heavily rely on EOL testing?

A5: EOL testing is indispensable in industries where product reliability and safety are paramount, such as automotive, machine manufacturing, electronics, appliances, and medical devices.

Q6: What are some examples of EOL tests in the automotive industry?

A6: In the automotive sector, EOL tests can include engine and powertrain testing, brake system testing, electrical system testing, ADAS calibration, NVH (Noise, Vibration, and Harshness) testing, and infotainment and connectivity testing.

Q7: How is EOL testing applied in machine manufacturing?

A7: In machine manufacturing, EOL testing focuses on functional performance, accuracy and repeatability, safety interlock verification, power consumption and efficiency, software and control system validation, and durability and stress testing.

Q8: Which test instruments are used in EOL testing?

A8: A variety of test instruments are employed, including Data Acquisition (DAQ) systems, various sensors and transducers (accelerometers, strain gauges, pressure sensors, temperature sensors, microphones, load cells), power supplies and electronic loads, oscilloscopes and multimeters, vision systems and cameras, communication interface testers, and robotics and actuators.

Q9: What is the role of Data Acquisition (DAQ) systems in EOL testing?

A9: DAQ systems are fundamental to EOL testing, acting as the central hub for collecting data from various sensors. They convert analog sensor signals into digital data for processing and analysis.

Q10: How do sensors and transducers contribute to EOL testing?

A10: Sensors and transducers convert physical phenomena into measurable electrical signals. For example, accelerometers measure vibration, strain gauges measure deformation, and microphones detect abnormal noises, providing crucial data for product evaluation.

Q11: How is EOL testing different from in-line testing?

A11: While in-line testing occurs during the manufacturing process, EOL testing is the final series of checks before products are shipped.

Q12: Does EOL testing include traceability and data logging?

Yes. Data acquisition (DAQ) and MES/ERP integration are used in EOL to provide traceability and data logging.

Q13: Is EOL testing performed on every unit shipped?

A13: Safety-critical products often require 100% testing, while others may use sampling based on risk and standards.

All trademarks are the properties of their respective owners.