Aircraft Structural Testing

Aerospace Structural Durability and Fatigue Testing

Dewesoft instruments help to design and build safer and better aircraft and spacecraft. Customers like NASA, Lockheed Martin, Boeing, Airbus, ESA, and many more rely on our flexible data acquisition systems every day, everywhere in the world. Flight test engineers trust our compact and rugged DAQ systems for physical measurements of all kinds. Ground station engineers take advantage of our full support for PCM and iNET telemetry data, and aerospace data buses like ARINC 429 and MIL-STD-1553. We offer stand-alone as well as distributable, networked DAQ systems into thousands of channels. From wind tunnels to launch gantries, Dewesoft is there.

Browse products

Aerospace Structural Durability and Fatigue Testing

Scaling power analysis from component to complete micro grid

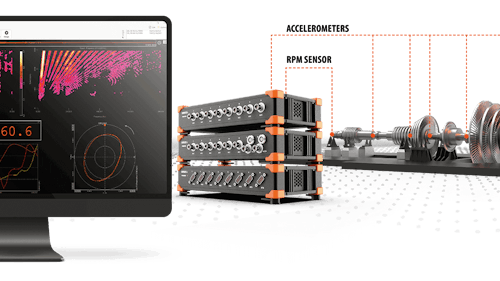

Instrumentation for complete testing of jet engines

Structural, Electrical, NVH, and Flight Testing Solutions

Telemetry data acquisition and analysis for flight test applications

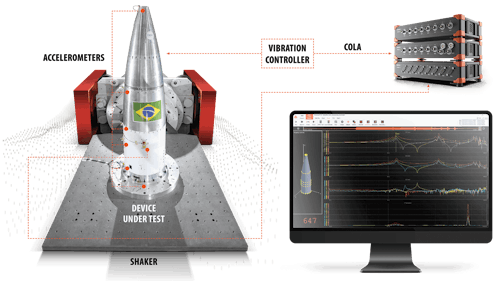

Sine Processing With Cola Signal

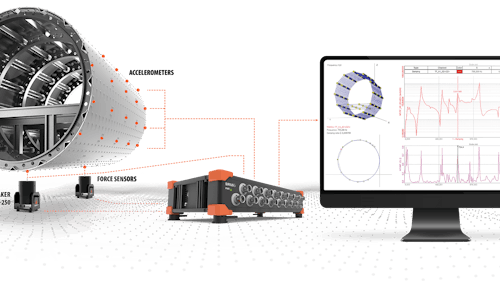

Structural dynamics testing and analysis solution

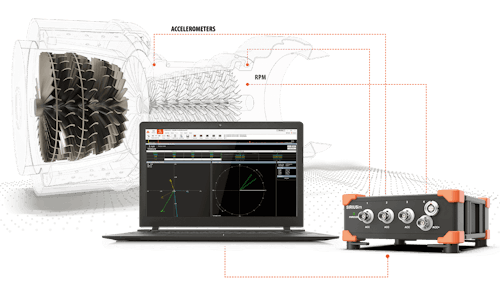

Noise and vibration analysis for rotating and reciprocating machinery

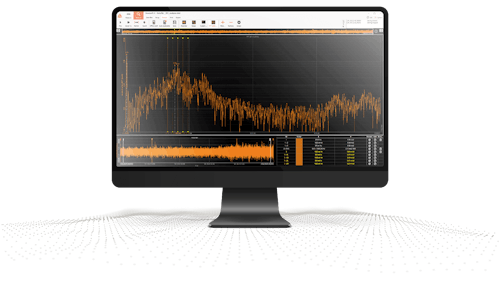

Vibration and frequency analysis with a Fast Fourier transform

Static and Dynamic Balancing of Rotating Machinery

Class 1 Sound Level Meter for Sound and Noise Level Measurement

Octave band frequency analysis solution for sound and noise

Case Studies

The AQUILO Rocket Team at Inholland University tested S-type load cells in tension and compression to improve rocket thrust measurement accuracy. Using Dewesoft’s SIRIUS DAQ and software, they evaluated 200 kg and 1000 kg cells, finding compression more accurate—by 76.9% and 40.9% respectively. The study highlights how load cell capacity and force direction affect data reliability, guiding future horizontal test stand designs.

Case Studies

Skyward Experimental Rocketry, a student team from Politecnico di Milano, developed and tested Aeneas, Italy’s first bi-liquid rocket engine. Using Dewesoft’s IOLITE platform, they built a precise data acquisition and control system to ensure safe static fire tests. The project advances hands-on rocketry education and paves the way for next-gen 3D-printed, regeneratively cooled engines.

Case Studies

Learn how hardware and professionals from Dewesoft played an essential role in testing and building a hybrid rocket engine, named Chimæra.

Case Studies

Faraday Rocketry UPV upgraded its static fire test setup with Dewesoft SIRIUS hardware and DewesoftX software, enabling precise, real-time measurement of thrust, temperature, and vibration for student-built rocket motors. The new system improved accuracy, reduced complexity, and matched simulation results, certifying the motor’s flight readiness and boosting the team’s future development capabilities.

Data Acquisition Knowledge Base

NASA’s Space Shuttle program relied on extensive ground testing to validate the Shuttle's engines, structures, and avionics. Using advanced sensors and data acquisition systems, NASA conducted hot-fire, vibration, wind tunnel, and flight simulations to ensure safety and performance. Key facilities, such as Stennis, Marshall, and SAIL, enabled rigorous validation, making data the cornerstone of the Shuttle’s engineering success.

Case Studies

The AQUILO Rocket Team from Inholland University conducted a static fire test of their PB-51C solid rocket motor, using Dewesoft’s DAQ systems to measure thermal and thrust data. Results confirmed safe casing temperatures but revealed unexpected thrust spikes, likely caused by ignitor holder failure. These findings will guide design improvements for their upcoming AQUILO IX rocket, targeting EuRoC 2026.

Case Studies

Learn how an aircraft operating company in Turkey wanted to modify the wing payloads without drastically affecting the flight envelope.

Data Acquisition Knowledge Base

Aerospace telemetry collects and transmits critical data—such as temperature, pressure, and speed—from onboard sensors to ground stations for real-time monitoring and analysis. Using specialized sensors, commutators, robust RF links, and synchronized ground receivers, telemetry guarantees accurate, time-aligned data that underpins mission safety and success.

Case Studies

See how company Spacelink tested and validated the new SL-2 hybrid rocket engine propulsion system using the Dewesoft data acquisition (DAQ) systems.

Case Studies

Dewesoft and NASA have developed a modern real-time telemetry system capable of monitoring several hundred thousand parameters in real-time.

Case Studies

Dewesoft provided the solution for a wide variety of tests to ensure the proper and safe operation of aircraft wheels and brakes for Parker Hannifin.

Case Studies

See how Dewesoft data acquisition systems are used to perform fitting and bonding control of the thermal protection system on the Dream Chaser space plane.

Case Studies

Dewesoft customer stories show how our customers did their jobs with a little help from some Dewesoft friends. Download PDF case study booklets now.

Case Studies

Dewesoft data acquisition and control systems were used on the test bench for testing ARIANE VI rocket propellant boosters. Read the entire case study.

Case Studies

Brazilian space institute DCTA is using Dewesoft sine processing solution to perform structural dynamic test of rocket nose. Read case study to learn more.

Case Studies

Learn how ISRO replaced its outdated measurement system with a precision DAQ system for mission-critical applications in aerospace research.

Case Studies

Large Dewesoft 2264 channel signal conditioning and data acquisition system is used at the structural test facility in Indian Space Research Organization.

Case Studies

Learn how Dewesoft replaced old DAQs for vibration monitoring on NASA's Crawler Transporter core systems that require precise time synchronization.

Case Studies

Learn more about car seat crash tests with dummies. The results are used in the automotive & aerospace industry to evaluate seat behavior during an impact.