Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Aircraft Wing Payload Modification

An aircraft operating company in Turkey wanted to modify the wing payloads without drastically affecting the flight envelope. Any aircraft is designed for a specific flight speed which is limited by wing flutter. Thus, anything that affects the natural frequencies of the wing has the potential to reduce the flight speed and narrow the flight envelope. This situation is not desired by the aircraft operators as reducing the speed of flight height will increase their operational costs and increase the flight durations.

The customer was a local aircraft operator who required a modal test of an aircraft wing. As the operator did not have an engineering department, they requested this test as an engineering service from the Dewesoft partner in Turkey, RMC Engineering. The flight envelope of the current configuration was unknown. Therefore, the wing modal test for current and modified configuration was performed. Moreover, it was a case of urgency, as the aircraft was only available for a very narrow time frame of two days.

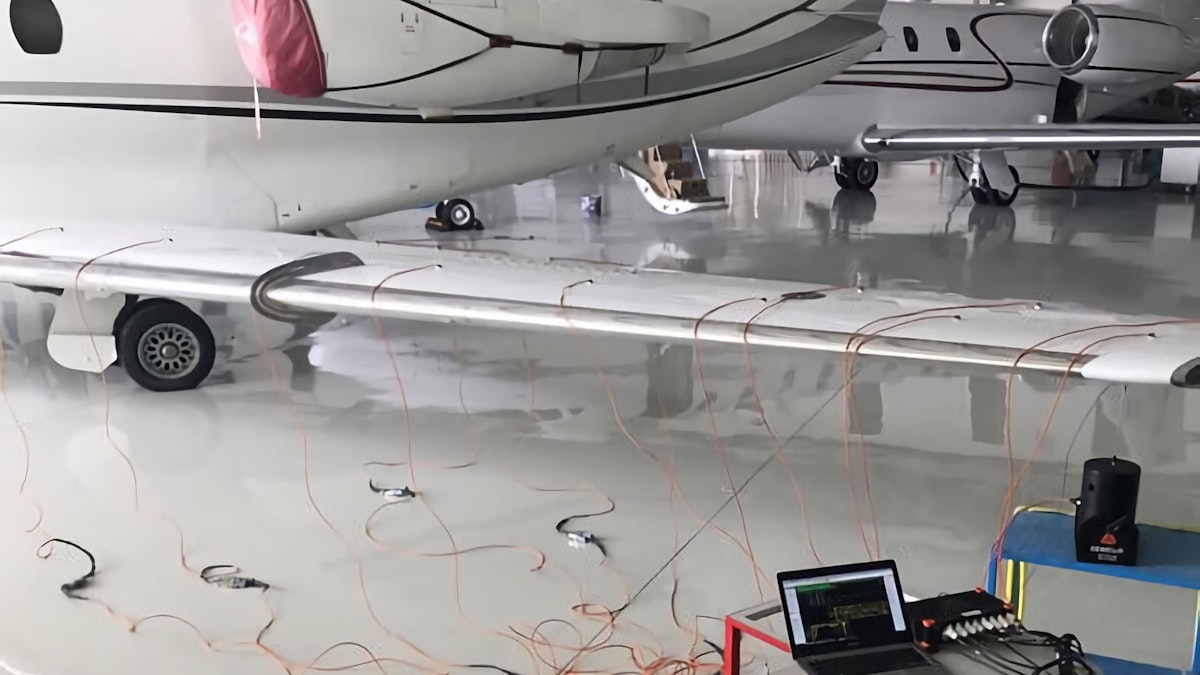

First of all, the pressure of the tires of the aircraft was lowered in order to have the aircraft boundary conditions similar to the flight. The tests had to be performed very fast where preliminary modal analyses were performed on-site only for data validation. The whole data acquisition and excitation process were completed with Dewesoft Sirius data acquisition (Sirius HD and Sirius STG with analogue outputs) and Dewesoft modal shaker MS-440 (440 N output force). Through the ease of use of the combined Dewesoft hardware and software the task could, in fact, be accomplished.

SIRIUS DAQ is a USB and EtherCAT data acquisition system designed to be flexible, modular, expandable, and secure. This simple to use device prevents frequent errors during the measurement process and offers virtually unlimited configuration possibilities. Slices are available from 1 to 16 analogue channel configurations that can be daisy-chained together. An array of different analogue amplifiers is available giving the possibility to connect virtually any sensor.

Modal shakers allow for modal testing of larger and more complex structures and the use of various excitation signals. The Dewesoft series of modal shakers are lightweight and powerful modal shakers, electromagnetic actuators, which can go up to 15 kHz and provide force levels up to 440 N with a maximum of 25 mm stroke.

In this case, the wing was instrumented with several uni-axial accelerometers – Dynalabs 3002DE - and a modal shaker was attached to the tip of the wing. The structure was at first graphically defined in the software geometry editor. Then the points of excitation and response were selected. The modal shaker provided force input and acceleration sensors the measurement of the response, acceleration output. The test points were excited while the software collected the data. The wing was excited with burst random excitations for 50 averages where acceleration signals were collected.

The preliminary mode shapes which were selected from the peaks of the frequency response functions (FRF) were animated in Dewesoft X Modal test plugin. This gave a quick insight into the quality of the measurements.

The Dewesoft Modal test software module is a plugin in Dewesoft data acquisition software. The Modal test module is designed for analysis of e.g. mechanical structures or electrical systems to determine the transfer characteristic (amplitude and phase) over a certain frequency range.

The Modal test module was used to generate burst random signals to the shaker and preliminary mode shapes were animated by choosing the peaks in the FRF plots. FRF plots are automatically calculated during the measurements allowing visualization of the phase and coherence of the measurement locations. Visualizing the preliminary mode shapes ensured the confidence in the quality of the measurements. The detailed analyses were performed later in the RMC head office.

The Modal test module is part of the Dynamic Signal Analysis (DSA) package along with a range of other modules e.g. Order tracking and Balancing. Along with the small and handy instruments, it constitutes a portable solution when coping with failure detection.

The modal tests and analyses concluded that the aircraft operator could use the aircraft with the payload modification. As the tests lasted only for two days the operations of the aircraft were not affected.

The modal testing of a wing of an aircraft normally takes a long preparation and execution time such as at least 2 weeks. However, the ease of use of Dewesoft data acquisition system with its modal shakers allowed us to complete the challenge in just two days.