Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Automating Aircraft Wheel and Brake Testing

Parker Hannifin - Laboratorio di test di qualifica AWB (Aircraft Wheel and Brake). Di Al Hoge, Ingegnere di Applicazione, Automazione e Controlli, Dewesoft USA

August 11, 2023

Parker Hannifin’s Wheel and Brake division conducts a wide variety of tests to ensure the proper and safe operation of aircraft wheels and brakes The laboratory was using different ageing instruments and systems to perform these tests. The engineers were looking for a new single system to carry out their array of tests. Dewesoft provided a solution to fit their needs.

For any testing laboratory, a transition to a new key technology is always a difficult process. As companies try to keep up with technology, build new capabilities, and improve efficiency, they confront an internal struggle between cost and productivity. From human nature, there is also an aversion to risk. It boils down to the expression “Why change it if it’s working?”

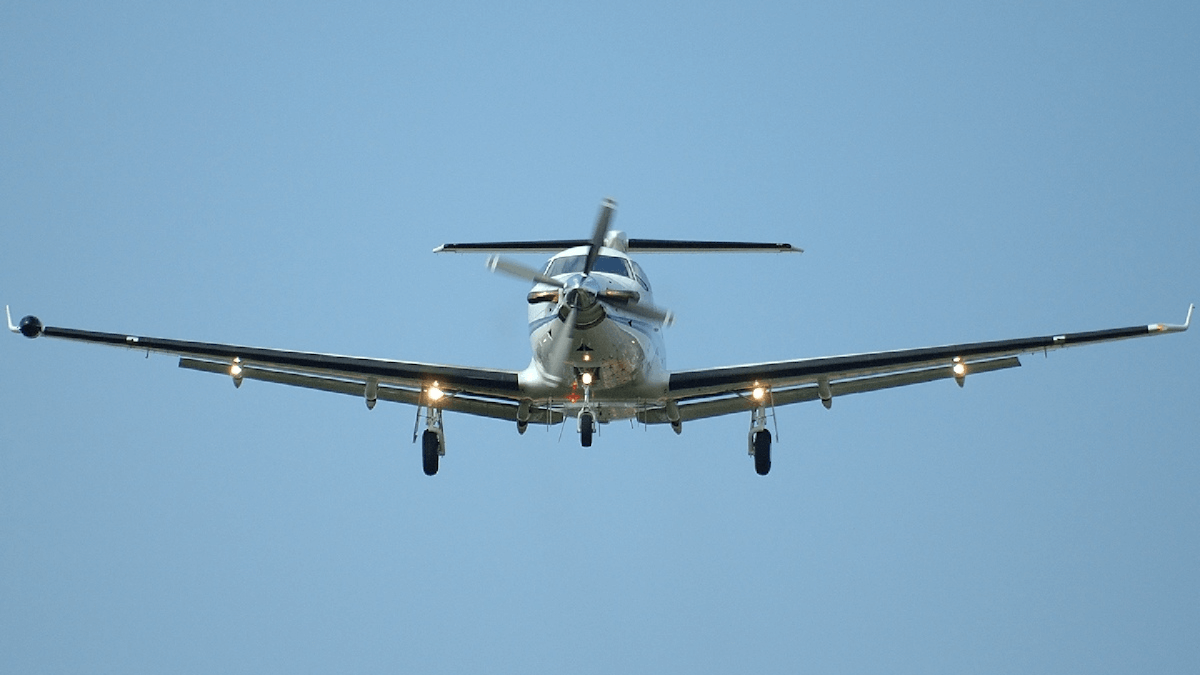

Since 1936 Parker Hannifin’s Wheel and Brake division has been a market leader in designing, building, and testing aircraft wheel and brake systems, as well as hydraulic products for general aviation, business aviation, rotorcraft, and military aviation applications.

Today, the unit operates under the auspices of Kaman Corporation but remains in Avon, just outside of Cleveland, Ohio. The division conducts a variety of tests to ensure proper and safe aircraft wheels and brake operation.

The issue - system integration and flexibility

The division’s Aircraft Wheel and Brake Qualification Test Laboratory (AWB) was using a collection of test and measurement instruments to perform these tests. It didn’t have a “system” per se, because the instruments were not synchronized, and each had to be operated individually.

Every test involved quite a bit of manual labour to set up, step by step. And, as multiple technicians were involved, configurations were not the same from test to test. The lack of an integrated data collection system meant that test configuration details and some of the data itself had to be logged by hand on paper.

AWB faced the classic question: should it go with a COTS (commercial off-the-shelf) DAQ system and try to adapt it to its specific needs, or should it use some DAQ hardware and spend months or years writing custom software using LabVIEW or another programming language? Was there something on the market that would give the best of both worlds and eliminate the time-consuming and costly programming?

Don’t get me wrong. AWB did the tests professionally and got good data, allowing them to produce quality products. But it was definitely not efficient. Finally, the laboratory consensus was - a truly integrated DAQ system is needed. One that would allow the technicians to set up tests the same way each time, simply by selecting them from a list in a completely integrated hardware and software instrument.

Such a solution would make the engineers happy because comparing data across multiple tests is much easier when the configurations are the same. Management would be glad about the improved efficiency, which means lower cost per test.

The application - aircraft wheel and brake testing

But before I talk about the solution that AWB implemented, I should review the kinds of tests they were charged to perform day in and day out.

Take-off and landing are the two most critical times in the operation of any aircraft. AWB is responsible for testing the main wheels, nose wheels, main brakes, and related hydraulic components.

Traceable, repeatable testing is critical for the certification process for new aircraft designs and ongoing maintenance and safety of existing aircraft fleets. The testing follows industry standards and regulations, such as those set forth by the Federal Aviation Administration (FAA), DO-160 and MIL specs, and the European Aviation Safety Agency (EASA).

The laboratory conducts these tests using a variety of test methodologies, including dynamometer, roll, combined load, endurance and impulse, proof and burst, and environmental testing. Here is a brief description of each of these applications:

Dyno (dynamometer) testing

Dynamometers or dynos allow engineers to simulate real-world conditions in a controlled environment. Dynos measure the torque and rotational speed of a wheel making contact with it. They enable simulation of the loads the wheel will experience during takeoff, landing, and taxiing. Applying loads to the wheel, the engineers can evaluate wheel performance under various conditions, including different speeds, temperatures, tire pressures, and loads. It allows engineers to assess the wheel performance in varying scenarios and make the required adjustments or improvements.

Combined load testing

Load testing evaluates the ability of the aircraft wheels and brakes to withstand the loads and stresses that they will experience during takeoff, landing, and taxiing. During combined load testing, technicians subject the wheels and brakes to a combination of vertical, lateral, and longitudinal loads, which simulate the actual conditions experienced by the aircraft.

Endurance testing

This testing allows engineers to evaluate the durability and longevity of the aircraft wheels and brakes under continuous use. During endurance testing, the wheels and brakes are subjected to a repeated stop-and-start series, simulating the cycles of takeoff and landing that an aircraft undergoes during operation.

Impulse testing

Impulse testing evaluates the ability of the aircraft brakes to withstand sudden and extreme changes in velocity or direction. During impulse testing, the brakes are subjected to sudden and intense stops, simulating emergency braking situations that could occur during an aircraft's operation.

Roll testing

Roll testing evaluates the wheels' ability to withstand the stress of taxiing and rolling during takeoff and landing. During a roll test, the aircraft is on a test stand, and a load is applied while its wheels are rolling to simulate the aircraft’s weight. These tests can identify any potential issues with the wheels or brakes, such as overheating, vibration, or wear, which could affect the safety of the aircraft during operation.

Proof and burst testing

This testing ensures the safety of aircraft wheels. Performing these tests, engineers can determine the maximum safe operating wheel pressure. They can verify that the wheel can withstand extreme loads without failing and operate safely and reliably under normal and emergency conditions.

There are even more tests, such as leakage testing, extreme temperature testing, temperature soak testing, and more.

Changing testing systems

The existing AWB “system” did the job but was getting older. Also, the “system” was a collection of separate instruments, each with its own display and interface. There were controllers, oscilloscopes, function generators, and more - all cobbled together. Nothing was automated.

The technicians had to keep paper logs of what they were doing while operating all of these separate instruments at the same time. They had no alarms, cycle control, or remote shutdown capability. The “system” worked but was not optimal.

AWB wanted a single system that could be adapted to perform its entire array of testing. But as mentioned above, they wanted to avoid a system that required even low-level programming - they didn’t have the time or resources for that. They selected Dewesoft as their provider for several key reasons:

The DAQ hardware is more than capable of providing the required sample rate and vertical axis resolution.

DewesoftX software comes with the hardware at no extra cost and without licensing or update fees.

DewesoftX software has a built-in sequencer allowing AWB to automate its tests. They can create step-by-step tests with user prompts and custom displays, using only macro-level configuration and no low-level programming.

In addition to its analog and digital inputs, it had analog and digital outputs that could replace the external controllers and function generators - everything could be completely integrated and automated.

AWB determined that a single Dewesoft SIRIUS module with four multifunction inputs and four low-voltage inputs can handle just about any type of dynamic signal that they encounter. The MULTI amplifier can natively deal with differing strain gages and load cells, low voltage, and potentiometric measurements. Adding a small DSI adapter, any MULTI input can connect to IEPE and charge accelerometers and mics, LVDT sensors, ±200 V signals, thermocouples, RTDs, and current sensors.

A selection of connectors is available, but AWB chose DB9 for the SIRIUS because their harnesses don’t change between tests, and multi-pin connectors allowed them to access sensor power and TEDS for automatic sensor identification.

AWB chose several highly rugged and water-proof multi-channel KRYPTON modules to expand the system for measuring temperature and additional voltage channels. Each KRYPTON TH module provides eight isolated universal thermocouple inputs. These modules can be placed close to the measuring point, which lowers the cost of expensive thermocouple wires.

Inside the module, data is converted to digital and sent to the SIRIUS via the EtherCAT interface, which also carries synchronization data and power to the module. All data, regardless of its source, is synchronized.

AWB also added a KRYPTON module with four additional voltage inputs on BNC connectors, bringing their analog channel count to 20. Notably, KRYPTON modules can withstand extreme operating conditions, shock, vibration, and temperature (-40 to +80 °C, which is -40 to +185 °F). In addition, hermetically sealed to IP67, they are impervious to water, dust, oil, and other particulates in the air. As a result, KRYPTON modules can be close to the measurement point.

A crucial factor in the selection of Dewesoft was the built-in sequencer in DewesoftX. It allows tests to be preconfigured and run with the required user prompts, custom displays, and even data outputs. The fact that the hardware included software with lifetime updates at no additional cost was also a return on investment advantage.

With this combination of hardware, software, and application knowledge, AWB can create a complete testing solution allowing everyone on the team to get repeatable, fully documented results.

After selecting the type of test in the software, a second dialogue appears that allows the user to choose a saved test or to create a new one.

Knowing and documenting the environmental properties is critical, so AWB set up a screen to capture those before each test:

The software’s flexibility has immense value. DewesoftX is a complete, standalone DAQ software package that does not require any programming. However, the built-in sequencer and other capabilities can adapt the software to specific test scenarios.

AWB now got the best of both worlds: a completely customizable DAQ software package without having to do any low-level programming. Any necessary changes can be done very flexibly, without the need to create something entirely new.

After running a test, the data can be presented graphically for review:

In playback mode, a yellow time cursor appears on the time-history displays - see Figure 8. Users can easily move the cursor simply by dragging it with the mouse. The value of the data in all of the other displays remains synchronized to the time location of the yellow cursor, making data review and validation fast and intuitive. Of course, the actual data is saved digitally and can be exported to various formats (e.g., MatLab® or Excel®) if further analysis is needed.

In the example below, AWB ran a Proof Pressure Test (<5K psig) - see the actual test results in Figure 9.

The new Dewesoft system allows the selection of many ramp rates required to meet various specifications. Compared to the older hardware, this is a huge advantage.

DewesoftX software records video in sync with analog and digital data. This dramatic data replay shows an aircraft wheel on the dyno as it makes contact, simulating a landing. The video and the data are synchronized. Note audio is included - the wheel against the dyno is audible:

Conclusion - before and after

Previously, AWB faced many limitations, including:

Keeping paper logs by hand,

Data were displayed across multiple separate instruments,

Separate instruments were not synchronized,

Limited to using analog relays,

Having to use external function generators as opposed to the programmable ones built into the Dewesoft system,

Having no way to add a synchronized video to the test results,

Multiple ways to set up tests, making it difficult to compare results later

No digital paper trail but relying on handwritten logs and data snapshots when reviewing data

No swift and easy way to output data to Excel providing reports to their customers

All these issues were addressed and solved by the new Dewesoft system.

AWB technicians can be more consistent than ever, and it takes them less time to set up and run each test. They only have to operate one instrument, and the sequencer steps them through test selection, setup, and operation.

AWB engineers now get a single file with all the data and notes in “it.” format. They can load the software freely on their computers and replay the data files, extracting whatever information and results they want from them. All of the data from every source is synchronized. They don’t have to question the test setup because a single file contains everything - including the test configuration.

Now, AWB has new capabilities that enhance the testing process, such as automated email alerts and aborts during tests. It can remotely view the data using simple VNC software. In addition,

Dewesoft includes a sensor database, and the laboratory has entered the calibration and EU data from all its commonly used sensors. This data makes setup simpler and documents each sensor’s unique calibration properties. The Dewesoft system even detects if a sensor has passed its calibration date so that AWB can substitute it with another sensor.

Implementing the Dewesoft system provided some additional unexpected advantages. For example, it pushed AWB to make firm decisions on the configuration of each test, the channel counts, and more. So now the lab and its results are more consistent than ever before, positively impacting time use and costs at AWB.

When implementing the new system, AWB started with just one test and then added another as each proved functional - a sensible and safe way to roll out a new system.

The Dewesoft hardware is expandable, too: additional SIRIUS and KRYPTON modules can be added in the future if needed. The implementation was a big success all around.

It’s always a little scary to replace a system that “works” with a new one. But in this case, the choice to go with Dewesoft was the right one. Now, AWB can more easily and efficiently perform its vital tests and get the data needed to build top-notch and safe aircraft wheels and brakes.