Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Testing High-Performance Engine Components with Dewesoft Combustion Analyzer

The components of today's premium-class and motorsport combustion engines are subjected to high, recurring loads during operation. Validating the quality of manufactured lightweight components such as pistons and connecting rods is essential to ensuring a long service life. Engineers conduct intensive testing on both tensile and compression testing machines in the laboratory and on test benches in real-world engine applications. The Testing Department of Pankl Racing Systems provides insight into its daily use of Dewesoft combustion engine analyzer (CEA) technology for detailed analysis.

Pankl Racing Systems has its headquarters in the small industrial town of Kapfenberg in southeast-central Austria, at the confluence of the Mürz and Thörlbach rivers.

The Pankl High-Performance division is a tier-one supplier specializing in developing and producing engine, chassis, and transmission system components. Customers include the automotive industry, various motorsports teams, and the aviation sector.

Pankl excels in these niche markets with lightweight components made from high-quality, innovative materials designed for extreme mechanical loads.

Component testing

The Engine Systems Department specializes in connecting rods, pistons, and crankshafts, available as individual components or complete systems. It carries out the component design in-house – from the initial design to the FEM calculation of the entire system.

Diplom-Ingenieur (DI) Elias Hillebold is responsible for the engine test bench. First, he showed me around the entire company, where I realized the complexity of this highly specialized development.

Connecting rods for racing are made from high-strength steel and titanium alloys, where Pankl has developed its manufacturing strategies. Engineers also apply the experience gained from racing to the series production of high-performance vehicles.

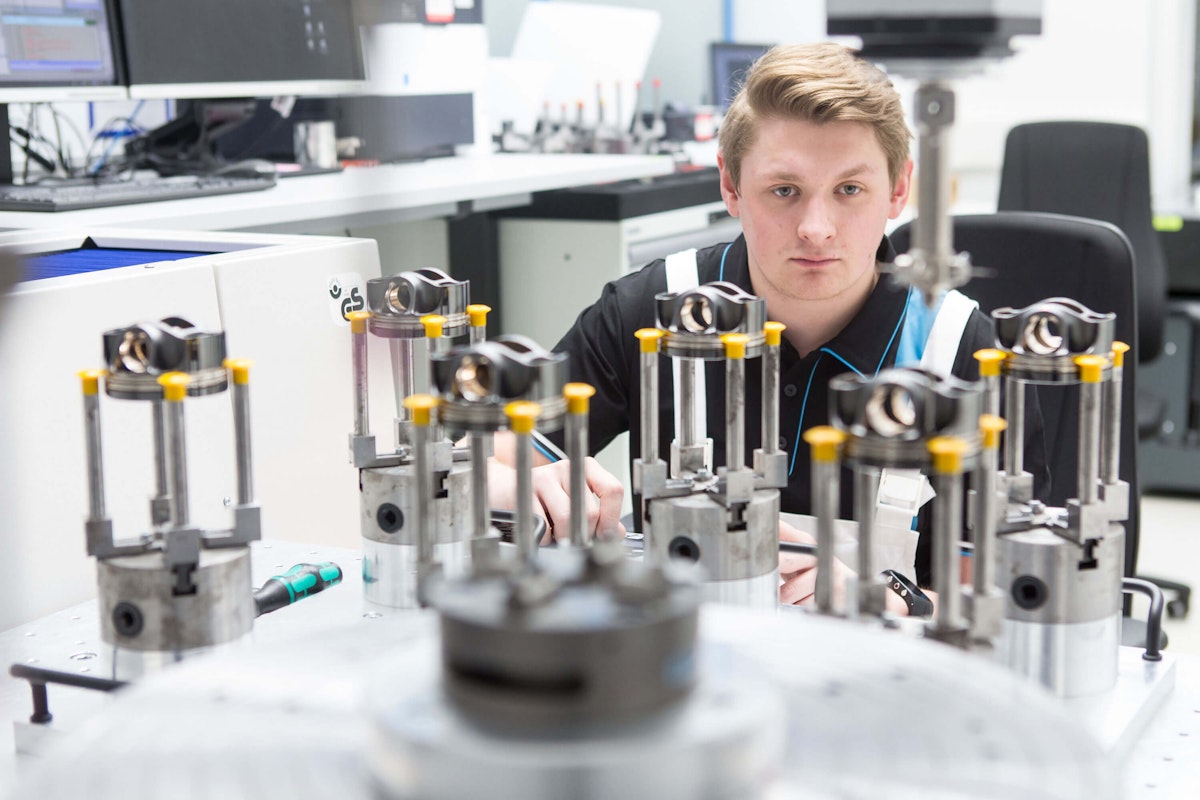

Engineers cut samples from serial products, cast them into specimens, and grind them flat. The surface texture is then analyzed using an electron scanning microscope. They also test existing and new materials for incoming goods inspections; oversized, colored images of metal surfaces hang throughout the office. One is amazed by the detailed process know-how and sense of passion the technicians bring to their work.

In addition to the tensile and compression testing machines, a fatigue strength test bench is available here. Currently, the operators are clamping a connecting rod to which they apply strain gauges. The resonance pulse excitation runs a frequency and amplitude profile for a defined number of cycles or fatigue under constant monitoring.

We enter the last room at the end of the corridor. The air smells of metal and fuel. Here is the engine test bench and its associated workshop. It is where the mechatronics engineer's interdisciplinary expertise becomes evident: multimeters and sensors sit alongside precisely manufactured, surface-treated metal parts.

The engine test bench and the test engine

Pankl Racing has developed its own single-cylinder combustion engine to test the manufactured engine components in real-world operation. This setup makes them less dependent on external test centers and allows for even greater detail.

Not everything always goes according to plan during development, so it is crucial, for example, to detect dangerous knocking at these high engine speeds promptly and to eliminate it to minimize damage.

Pankl Racing, therefore, has two primary objectives: the continuous development of combustion engines and the in-house testing of their components.

Equipment and software used

The universal Dewesoft SIRIUS measurement system, in its high-speed 1 MHz version, is ideally suited for the highest angular resolution requirements.

SIRIUSi-HS-6xCHG-2xCHG+ - a high-speed SIRIUS measurement system, 1 MHz per channel, eight analog inputs for charge/IEPE/voltage + 2x fast digital angle sensor inputs

DewesoftX CEA-BASE and CEA-ADVANCED – software options for incineration measurements and calculation of combustion parameters (e.g., thermodynamics) in DewesoftX data acquisition and signal processing software

DewesoftX OPT-CAN (included with SIRIUS, CAN port on the rear of the device) – software option for communication with the control unit (receiving and sending CAN bus data)

L1B7m-3xBNC-BOX - a connection box (Bayonet Neill-Concelman) designed to maintain the characteristic impedance of the cable across the connection for the crank angle sensor (3x BNC to 100 MHz SIRIUS counter input)

DewesoftX PLUGIN-CA-TESTBED - a software option for Ethernet communication with the KS Engineers' test bench

Measurements and results

Since Formula 1 regulations have reduced the fuel consumption to approximately 100 kg, today's combustion engines must operate with a much leaner air/fuel mixture, which means that individual components, such as the ignition system spark plugs, must be constantly customized and adapted to the engine.

The prechamber ignition principle has been known for more than 100 years. Engineers initially applied it to early diesel engines, and it remains widely used in gas engines and large power generators. However, it has also found an application again in Formula 1 and functions as an ignition system.

This principle enables spark-ignition engines to operate in lean air-fuel conditions, improving fuel efficiency, saving around 20% of fuel, and reducing emissions. It works so that a smaller fuel volume is injected into the prechamber and ignited with a conventional spark plug.

The extremely hot flame jet streams out of the chamber through mini nozzles, forming a star pattern in all directions, and ignites the rest of the mixture in a shorter time and more completely than a traditional spark plug. The ignition of the main chamber happens much shortly before the OT point.

The challenge in development is precisely controlling the injection in a small chamber, which must operate accurately under all varying engine conditions. Engineers conduct numerous CFD (Computational Fluid Dynamics) simulations to gain a deeper understanding and more accurate behavior predictions. Another problem is the very high temperature inside the prechamber.

To evaluate the performance increase of the component changes, which CEA parameters are now most interesting for the customer?

The mass conversion points - MFB (Mass Fraction Burned) - at 10%, 50%, and 90% are of main interest," explains Elias Hillebold. “These MFB-points give insight into the combustion speed of the engine. The curve should be as steep as possible to reach the highest engine efficiency.

While reviewing the measurement data for this case study, we coincidentally discovered the gas exchange curve option in the CEA Scope widget. We found this setting very useful; previously, we had to export the data to MATLAB to access this display.

The engineers use the gas exchange curve to determine how the exhaust system influences combustion. A suction effect occurs at the exhaust pipe, causing a pressure pulse at the intake. Tuners intentionally use this effect to achieve more power.

Conclusion - module widely applicable

Pankl Racing initially purchased the SIRIUS measurement module and the CEA software plug-in exclusively for the combustion measurement, i.e., recording and evaluating cylinder pressures and crank angles. Engineers collected data and calibrated the model, enabling a comparison of the CFD calculation.

Shortly thereafter, Pankl Racing Systems also acquired the Testbed Plugin, which enables direct, live transmission of measurement data to the Kristl Seibt Tornado test bench. The plugin is essential for detecting early knocks and forwarding them.

Since then, the application area has expanded to include many additional measurement channels. The engineers verify ECU data (parameter verification), record injector current using current clamps, and measure delay times. Simultaneous recording from a load cell provides further insights. The Testbed Plugin and the CEA module can be combined to identify all influencing factors and optimize the ECU's parameters.