Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Testing and Validation of a Brake Disc Model for a Formula SAE Car

UniNa Corse Racing Team

University of Naples

December 4, 2025

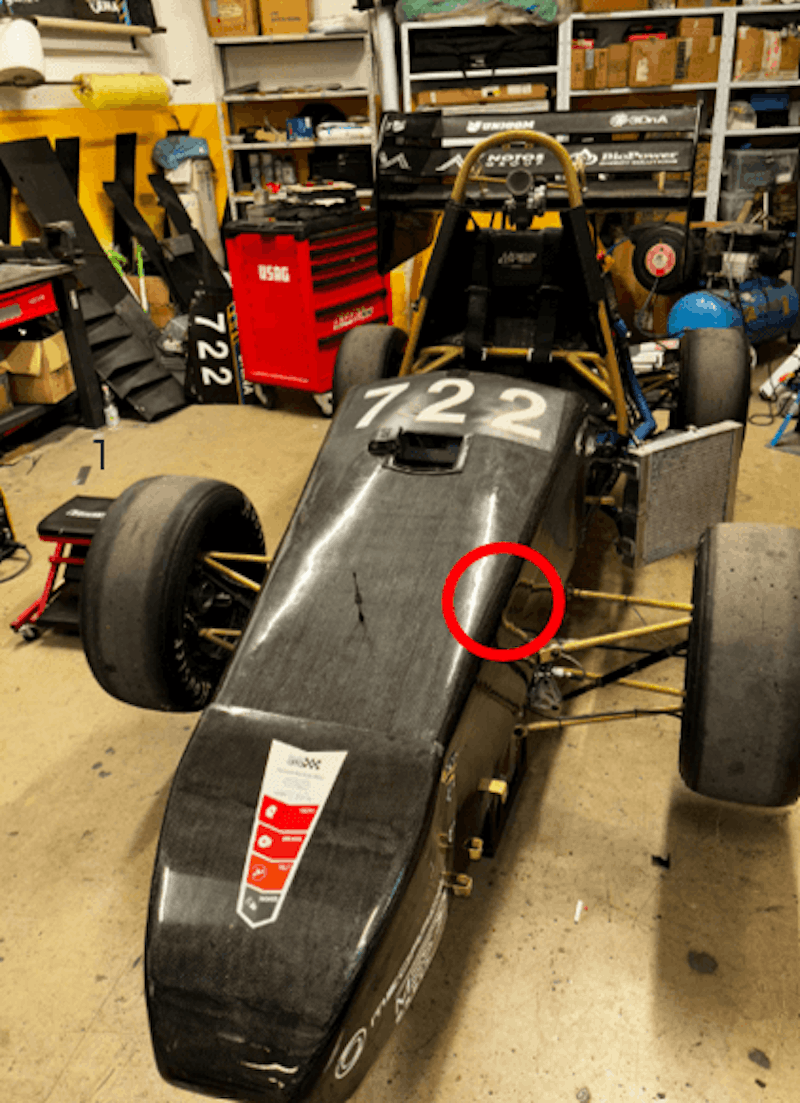

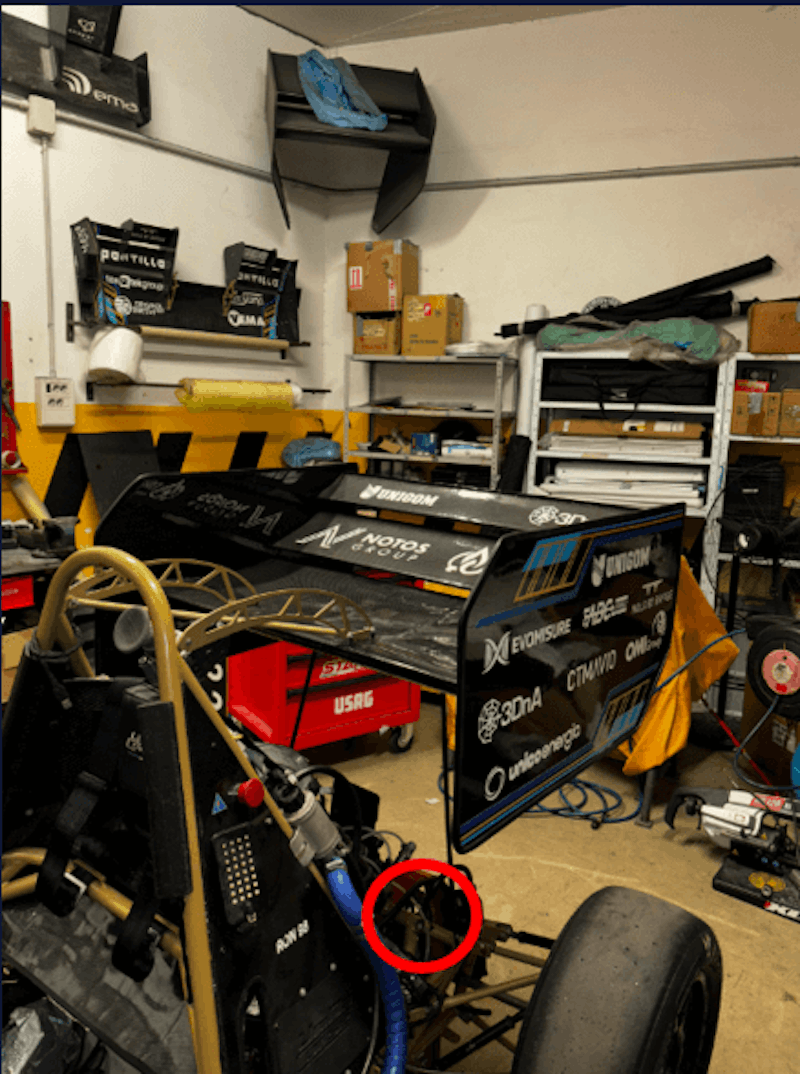

To build their first fully electric Formula SAE car, Nura, the UniNa Corse Racing Team from the University of Naples analyzed the brake disc system’s thermal behavior in detail. They used advanced sensors and Dewesoft data acquisition tools to compare simulation models with real track data. This helped them fine-tune the design for better performance, reliability, and safety on the race track.

In the 2025/2026 season, the UniNa Corse racing team from Federico II University of Naples took on the ambitious challenge of designing, building, and racing a fully electric car - pushing the limits of innovation and engineering.

To meet this challenge, the team conducted multiple tests on the track to validate the thermal model of the brake discs. This enabled them to have a more informed and accurate design for the new electric car - “Nura”.

Full engineering team members:

Angelo Cuccurullo, Mechanical and Performance Engineer

Davide Nicolini, Automation Engineer, Electronics Division

Giuseppe Greco, Mechanical Engineer, Dynamic Division, and

Andrea Pezzulo, Aerospace Engineer, Aerodynamic Division

Formula Student and UniNa corse

Formula SAE is an international university competition in engineering design, initially proposed by the Society of Automotive Engineers (SAE). The competition involves designing and producing a racing car. A panel then evaluates it based on its design qualities and engineering efficiency.

The UniNa Corse racing team has been participating in this competition since 2015 with an internal combustion vehicle. Since 2021, the team has also implemented autonomous driving capabilities on its vehicles, the latest of which is named Gaiola. During the current 2024 season, the team is designing its first electric vehicle, which will be used to compete in the 2025 season.

For the new electric car, we will completely revolutionize the design of the brake discs. To make this change safely and reduce structural and reliability risks, it was essential to understand the thermal exchange process.

A general overview of the two cars’ specifications is in Table 1.

| Specification | Numerical Value Gaiola | Numerical Value Nura |

|---|---|---|

| Mass (car + driver) | 330 kg | 280 kg |

| Sprung Mass | 210 kg | 150 kg |

| Unsprung Mass | 50 kg | 60 kg |

| Wheelbase | 1565 mm | 1535 mm |

| Front Track | 1200 mm | 1200 mm |

| Rear Track | 1190 mm | 1180 mm |

| Wheel | 13’’ | 10’’ |

| Suspension System | Pull-rod | Push-rod |

The challenge

The brake disc is a fundamental component in the design of a Formula Student car. It directly affects the vehicle’s overall performance. A well-designed car enables awareness of its limits and capabilities, allowing for the identification of areas for improvement.

The brake disc is a highly complex component, not only from a dynamic perspective but also structurally and thermodynamically. After defining its dimensions to ensure proper function and effective braking, the component must also withstand operational loads without deforming—since any deformation could reduce performance.

In addition to mechanical resistance, the brake disc must endure sudden temperature fluctuations and high thermal stress. Due to the intense friction it experiences, it heats up significantly, and at elevated temperatures, its physical properties change, ultimately affecting overall performance.

To manage these effects, we conducted detailed thermo-fluid dynamic analyses. We monitored temperature trends and, most importantly, refined the brake disc geometry for optimal heat dissipation.

In cooperation with Radio6ense and Dewesoft, the team conducted a measurement campaign to measure the temperatures of the vehicle's brake discs under various dynamic conditions.

We carried out all analyses on our previous car, “Gaiola”. Since only the vehicle geometry changes, the model's validation remains unaffected. This method allowed us to leverage an existing vehicle to enhance the design of the next model.

The Braking systems

Table 2 highlights the main differences between the two braking systems.

| Specification | Numerical Value Gaiola | Numerical Value Nura |

|---|---|---|

| Effective radius of front brake rotors | 97 mm | 83 mm |

| Effective radius of rear brake rotors | 97 mm | 83 mm |

| Total area of front brake caliper pistons | 3617.28 mm2 | 1808.64 mm2 |

| Total area of rear brake caliper pistons | 3617.28 mm2 | 1808.64 mm2 |

| Diameter Master Cylinder Front | 15,88 mm | 15.88 mm |

| Diameter Master Cylinder Rear | 19.05 mm | 16.88 mm |

| Hydraulic Pressure Front (1g Deceleration) | 32.5 bar | 74.0 bar |

| Hydraulic Pressure Rear (1g Deceleration) | 24.0 bar | 35.0 bar |

The analyses conducted, however, do not fully align with reality, as we currently lack a means of validation comparison. This situation necessitates a dedicated test campaign, enabling us to gather the necessary data to compare our analyses with real-world results. By ensuring a well-calibrated model and analysis setup, we can optimize the design process for maximum efficiency.

To do this, we have followed the following scheme of work:

The challenge lies in ensuring that the sensors used are both precise and reliable, capable of delivering accurate data for analysis and interpretation. Additionally, a well-structured acquisition system is essential for effectively monitoring all the car's parameters, allowing for the faithful reproduction of the simulations.

With Dewesoft, we chose the best configuration for the considered application.

Sensors and measuring instruments

Table 3 outlines the sensor setup.

| Measurement Value | Sensor | Conditioning / Acquisition |

|---|---|---|

| Brake Disc Temperature | Thermocouple | RFID |

| Brake Disc Surface Temperature | Infrared | 5V analog input |

| Shock absorber relocation | Linear potentiometer | 5V analog input |

| Wheel speed | Hall Effect sensors | Counter input |

| Steering angle | Linear potentiometer | 5V analog input |

| Brake pressure | Pressure sensor | Voltage input |

| Vehicle acceleration | IMU | CAN bus |

| Engine Control Unit (ECU) | MaxxEcu Race H20 | CAN bus |

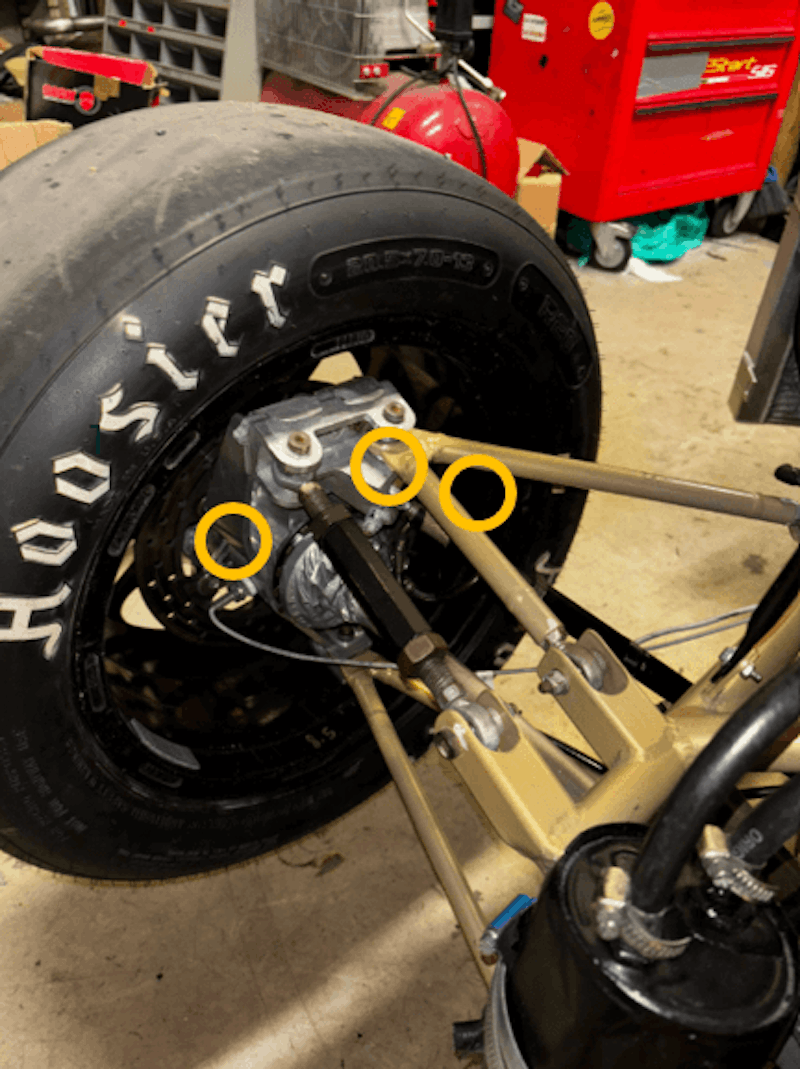

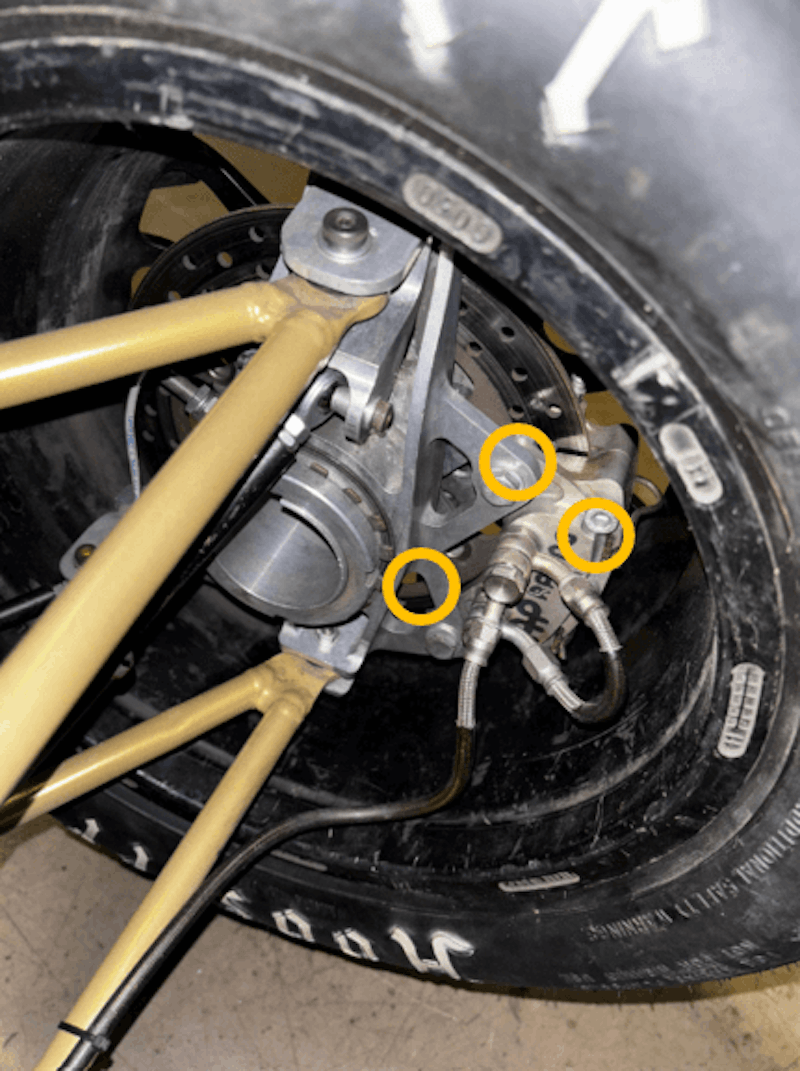

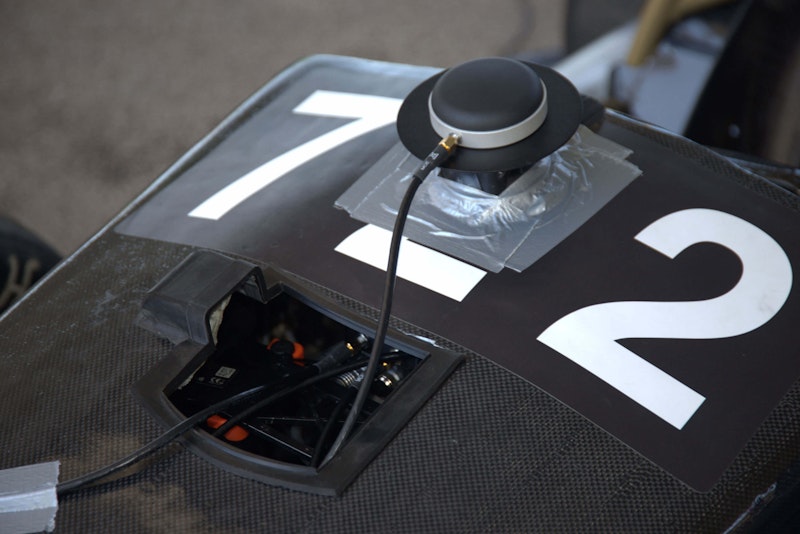

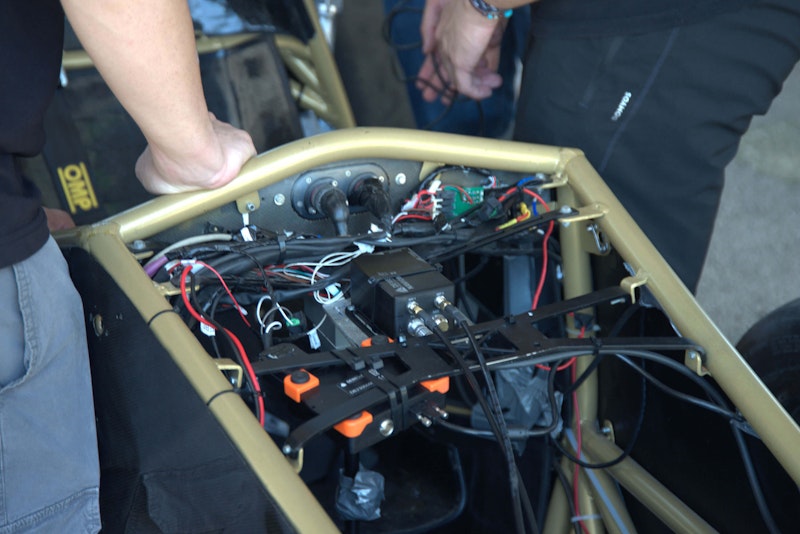

Dewesoft provides the brake disc temperature data acquisition system via the SixSense kit. The architecture consists of a RAIN UHF RFID main reading unit connected to two interrogation antennas, located in the front and rear sections of the car, respectively. These antennas act as feeders, using electromagnetic emission, for the temperature sensors located on the surface of the brake discs and in the surrounding areas, such as the hub carrier and brake caliper:

They are, in fact, wireless passive thermocouples, providing power supply and data transport, which is an optimal solution as it eliminates the need for sensor wiring, ensuring high ease of installation, maintenance, and accuracy.

In addition to the Radio6ense package, an Aviorace infrared brake disc sensor, model IR1000, was added. This sensor measures the surface temperature of the brake disc, and we positioned it so that the beam includes the entire surface that comes into contact with the pad.

Lastly, Dewesoft supplied the Navion-i2 inertial measurement module for acceleration and position acquisition, as well as an onboard computer.

The remaining sensors are managed by the dashboard already installed in the car. Their outputs travel along a pre-existing CAN line, which transmits data to the onboard computer, where we process it for subsequent analysis.

The quarter-car model

We conducted the analysis on the front wheels. Specifically the front left wheel, as this is subject to the highest thermal stress due to the significant braking force exerted by the brake pads. For this reason, we developed a simplified quarter-car model, which we designed to focus on the thermo-fluid dynamics of the brake rotor.

We carried out the pre-processing using ANSA, including the definition of an appropriate control volume for the surrounding fluid to avoid non-physical conditions at the boundaries and ensure the correct evolution of the flow. We set the boundary layers according to the flow properties and the turbulence model, and selected the k-omega SST to provide a detailed evaluation of fluxes and gradients near the walls.

After generating a high-quality mesh, we conducted computational fluid dynamics (CFD) simulations using Ansys Fluent. Based on data obtained from previous tests, we defined plausible braking scenarios. Specifically, from the deceleration corresponding to the analyzed braking maneuver, the kinetic energy dissipated as heat, 𝑄, by the brake disc was calculated to study the resulting temperature increase, as expressed by the following system, assuming a lumped parameter approach.

We assumed that the brake disc dissipates 97% of the total heat:

mv = mass of the vehicle;

m = mass of the disc;

v = vehicle speed;

cp = specific heat capacity of the disc.

Once we determined the temperature reached by the disc, we analyzed the heat dissipation process through CFDs to obtain a realistic trend of the convective heat transfer coefficient at different speeds and flow conditions. The output values were then interpolated and used to perform Transient Thermal Analyses in Ansys, evaluating the thermal evolution of the disc under realistic operating conditions, such as dynamic events the vehicle encounters in competitions.

The testing

The test campaign took place at the “Circuito Internazionale Del Volturno”, a track characterized by long straights, constant-radius curves, and mixed sections. These varied features made it an ideal testing ground for evaluating the brake discs under different conditions.

We did the test session in one day. We carefully selected the maneuvers during the preparation phase to obtain as complete an acquisition as possible. They reproduced both the conditions in thermo-fluid dynamics simulations and the dynamic events of the competition.

During the session, we performed the following maneuvers:

Pure braking, 70 to 40 and 90 to 20 km/h with 6s at constant speed

Autocross, complete laps at max-performance

Endurance, 22km at max-performance

After completing the data collection phase, we first examined the quality of the acquisitions. The results were highly satisfactory, and the high sampling rate achieved with the Dewesoft hardware enabled the performance of data filtering operations without compromising accuracy.

Data analysis and results

Regarding the Radio6ense instrumentation, the acquired data corresponds to an autocross lap, during which we positioned three sensors in the following areas: Banjo, brake caliper, and brake disc.

It is important to note that the temperature trend varies, influenced by both the amount of energy exchanged in different zones and the material analyzed. These factors contribute to distinct thermal behaviors across the monitored components.

The graph presented is an autocross run. It highlights the temperature evolution during the run and the quality of the acquisitions of each sensor.

During the validation phase, we compared the maneuvers performed on the track with the simulations. Despite some discrepancies due to model approximations, the similarity between trends and peak values remains appreciable.

In conclusion, we have successfully identified the main shortcomings of the current models, laying the groundwork for future improvements. This insight will enable refinements that enhance accuracy and bring the models closer to real-world conditions, ultimately contributing to a more effective design of the brake system.

Conclusion and acknowledgements

Validating the calculation tools was essential for understanding the limits and reliability of the mathematical model, enabling accurate predictions of heat buildup affecting the brake disc

We extend our sincere thanks to the entire Dewesoft Italia team for their support throughout this project. Special recognition goes to Riccardo Petrei and Davide Carniani for making the test campaign possible and for consistently providing technical assistance during both the installation and track testing phases.

Special thanks go to Radio6sense, especially Alessio Mostaccio, for providing us with their state-of-the-art temperature measurement equipment and for their support. Finally, we would like to thank the entire UniNa Corse team.