Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Structural Health Monitoring of the Prestressed Concrete Bridge in Sweden

As heavy mining trucks rumble across the aging Autio bridge in northern Sweden, engineers aim to understand its hidden vulnerabilities. Built in 1963, the bridge is now closely monitored by a network of advanced Dewesoft tailor-made data acquisition devices, transforming it into a living laboratory. The final act of the bridge: teaching future generations how to manage, maintain, and design safer, more innovative infrastructure.

As Sweden’s infrastructure faces growing pressure from modern demands, the aging Autio Bridge—frequently crossed by heavy mining trucks—has become both a structural challenge and a valuable research opportunity.

Engineers from Luleå Technical University and Dewesoft Sweden have transformed this cracked, prestressed concrete bridge into a full-scale monitoring lab. They have equipped it with high-precision sensors to study its behavior under load and climate stress. The project not only safeguards public safety but also supports the development of future-ready digital tools for managing bridges nationwide.

A bridge of the ’60s

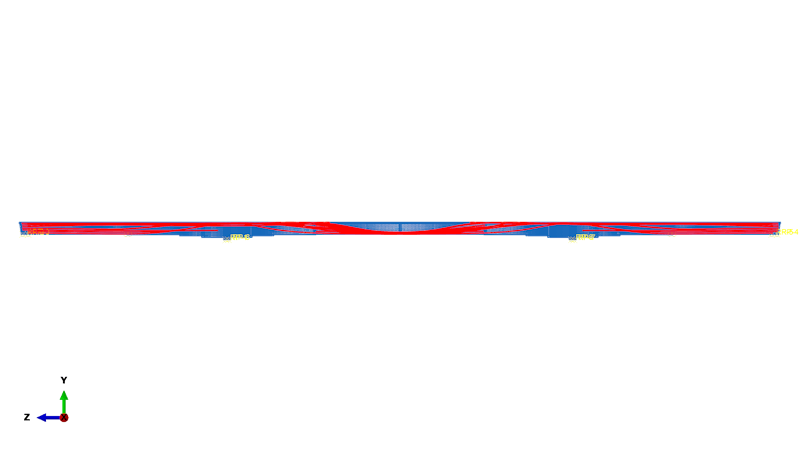

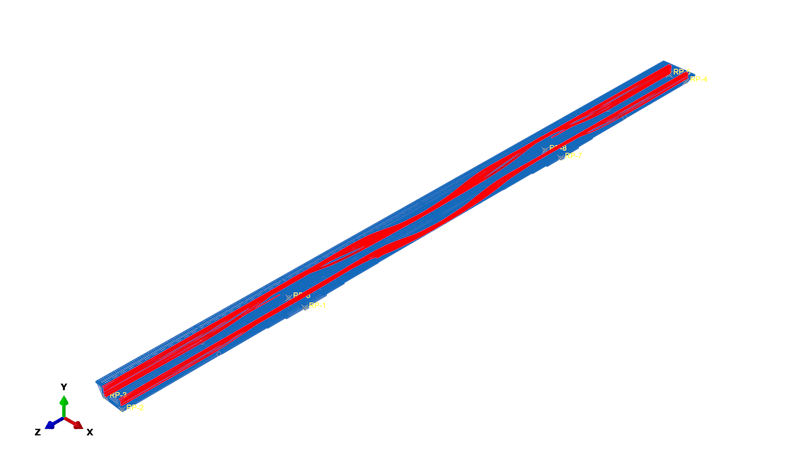

Designed and built by Byggnads AB Contractor in 1963, the Autio bridge is a continuous three-span structure stretching about 135 meters across the Torne River. Its design utilized the cutting-edge technique of prestressing. Think of it like a building with blocks that have a giant, invisible rubber band stretched through them, squeezing them tightly together.

In concrete, prestressing involves threading high-strength steel cables, called tendons, through ducts within the concrete beams and then pulling them tight before anchoring them in place, putting the concrete itself under compression.

Concrete is excellent at handling compressive forces, but weak when subjected to tension. However, by applying compression beforehand, the concrete can resist the tension forces that bending and loads would usually create, allowing for longer, shallower beams than traditional reinforced concrete.

The Autio bridge utilized a specific system called BBRV, where each cable consisted of 32 thin steel strands, akin to robust wires bundled together.

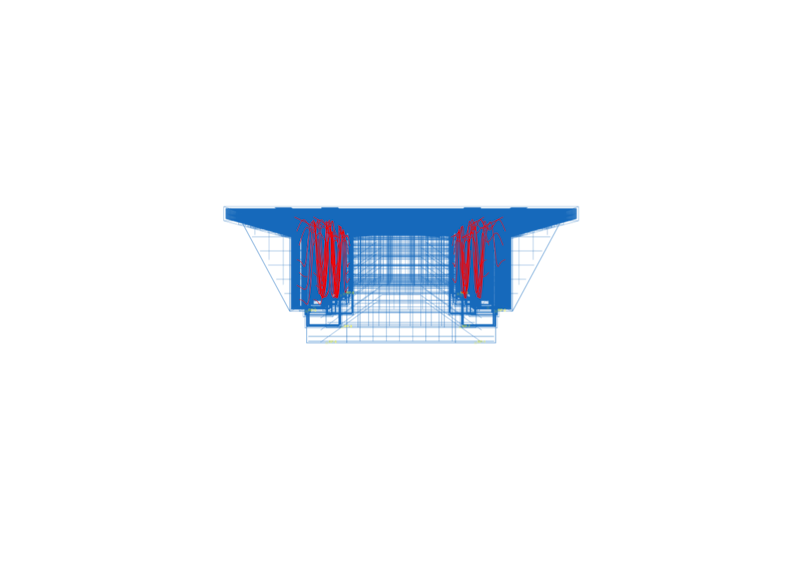

The bridge's main beams are substantial, measuring approximately 0.7 to 1.0 meters in width and over 2 meters in depth in some places, and supporting a concrete deck. The concrete itself was specified to be quite strong for the era, with a compressive strength of approximately 45 MPa (K450) for the beams and 30 MPa (K300) for the deck. The main steel reinforcement bars were Ks40 (yield strength of 400 MPa) in the beams and Ks60 (yield strength of 600 MPa) in the deck slab.

While the main prestressing cables provide the primary strength against bending, smaller steel bars (rebar), called stirrups, are placed vertically within the beams. These stirrups’ primary function is to help the concrete resist forces that attempt to slice through the beam, known as shear forces.

In the Autio bridge's original design, the engineers believed the prestressing and the concrete itself would handle most of the shear, so they included only minimal stirrups – slender Ø10 mm bars spaced 250 mm apart. This seemingly minor detail would later become a key player in the bridge’s story.

The challenge: heavy mining trucks

In recent years, engineers inspecting the Autio bridge began noticing thin, almost horizontal cracks appearing in the main beams. These weren't random surface blemishes; they were significant, running along the beams, often parallel to the prestressing cables. Initially, around 20 cracks were noted in 2014, typically measuring a hairline width. However, by September 2020, the count had risen to approximately 60, some reaching widths of up to 0.5 mm and stretching an alarming 33 meters long.

Why was this solid concrete bridge cracking? Engineers suspect a few reasons:

Old design assumptions

Engineers in the 1960s might have overestimated the concrete's ability to resist tension forces in shear compared to what modern standards recognize.

The passage of time and harsh climate

Concrete changes over decades. Natural processes, such as shrinkage and creep (slow deformation under sustained load), can alter the stress distribution. Furthermore, the Autio bridge in Northern Sweden is in a region known for extreme temperature variations. The concrete repeatedly expands in the summer heat and contracts in the frigid winters. This large temperature delta, potentially over 60°C annually, causes significant stresses within the structure.

Prestressing losses

Although designed to maintain tension, prestressing forces can gradually decrease over time due to relaxation in the steel and creep or shrinkage in the concrete. If the "rubber band" loosens slightly, the concrete has less protective compression.

All these factors combine to create tensile stresses. Where these stresses exceed the concrete's limited tensile strength, cracks form. And here's where those minimal stirrups come back into the picture: they aren't robust enough to hold these tension cracks tightly closed and stop them from spreading.

Adding to the stress is the changing nature of traffic. The Swedish Transport Administration (Trafikverket), which is responsible for the country's road network, owns the Autio bridge. However, a significant user of this bridge is the mining company Kaunis Iron, whose heavy trucks, weighing up to 90 tons, transport iron ore across the river.

These trucks, far heavier than the standard vehicles of 1963, exert forces that go beyond the bridge's design capability. While assessments indicate that the bridge likely has sufficient capacity to handle the bending forces from these trucks, the repeated passage of such heavy loads places immense stress on the internal structure, particularly testing its shear capacity and the fatigue life of the slender stirrups.

Fatigue is akin to metal becoming "tired" – repeated cycles of stress, even if below the strength limit for a single load, can cause microscopic damage that eventually leads to failure. The engineers worry that the constantly stressed stirrups are susceptible to this type of failure.

Bridge under microscope: structural health monitoring

To understand the bridge's hidden struggles, engineers installed a sophisticated monitoring system to understand the structural responses of the bridge.

Strain Gauges: Tiny sensors, either glued directly onto the concrete surface or, more importantly, spot-welded onto the steel reinforcement bars (FTG-ARM), measure the stretching (tension) or squeezing (compression) of the concrete or steel.

Deflection Sensors: Devices like the Noptel system measure the degree to which the bridge beams sag under the weight of traffic.

Crack Monitoring: Regular measurements track if and how the visible cracks are growing.

Temperature Sensors: Installed to help differentiate stress changes caused by temperature fluctuations from those caused by structural issues.

This monitoring system, with its complex wiring and data acquisition units (DAQ), provides a continuous stream of information. The rationale behind monitoring this specific bridge is multifaceted. Firstly, an immediate safety assessment is necessary, given the cracking and heavy loads. Still, it also presents a valuable research opportunity to study the long-term behavior of an aging prestressed concrete bridge built to older standards, particularly its shear capacity and fatigue performance under modern traffic and climate conditions.

From repair to replacement

For a time, the monitoring revealed a slow, expected increase in crack widths and relatively low stress ranges in the steel reinforcement, even under normal traffic conditions, with the presence of heavy trucks.

However, in early November 2020, the monitoring system detected "disturbing changes" – data that indicated something unusual was happening. While the exact cause, possibly new cracking or issues with the sensors themselves, was immediately investigated, the uncertainty and potential safety implications were too significant. As a precaution, Trafikverket stopped traffic on the Autio bridge on November 11th, 2020.

Following detailed assessments, including analysis of the original design documents and recent calculations, the engineers confirmed that while the bridge's bending capacity appeared sufficient, the potential issues with shear capacity and stirrup fatigue were real concerns, directly linked to the observed cracking.

These findings, coupled with the long-term challenges posed by the bridge's age, its specific design vulnerabilities, and the increasing demands of modern heavy traffic, led to a significant decision. Despite the detailed analysis showing no immediate danger, the long-term plan for the Autio bridge shifted from potential strengthening to complete replacement.

The authorities took the decision: the Autio bridge is scheduled for demolition and removal, making way for a new bridge at the exact location. Demolition will begin in mid-June 2025.

Monitoring for the future

The Autio bridge, as a research subject, didn't end with the 2020 traffic closure or the decision to demolish it. The engineers saw an opportunity to gain even more invaluable data from the structure in its final years, turning its impending retirement into a teaching moment for future bridge management.

After the closure in 2020, engineers installed additional sensors. Among these were 16 accelerometers strategically placed across the top of the bridge deck. These weren't just about monitoring daily safety; they had a crucial dual purpose for this final phase of the bridge's life and beyond.

Engineers carefully installed these small, sensitive devices directly onto the bridge surface. To ensure secure placement, they were secured to robust metal mounting plates screwed directly to the concrete structure (see Figures 5, 6, and 7). The installation process was remarkably efficient, requiring only one day for two engineers to secure all 16 accelerometers and their associated wiring across the bridge deck.

These accelerometers are part of a sophisticated Dewesoft monitoring system. A significant advantage of this system is its use of EtherCAT technology, which enables the accelerometers to be daisy-chained.

Thus, multiple sensors can be connected in a series, drastically simplifying the wiring. Instead of running individual cables back from each of the 16 accelerometers, the EtherCAT system requires only two cables (acting as input connectors) to be run back to the central data acquisition unit (DAQ) installed conveniently on the abutment of the bridge (See Figures 9 and 10)

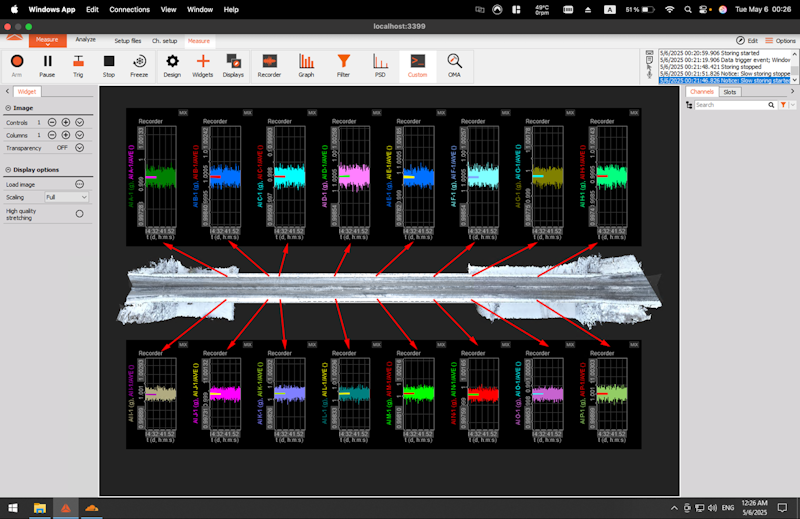

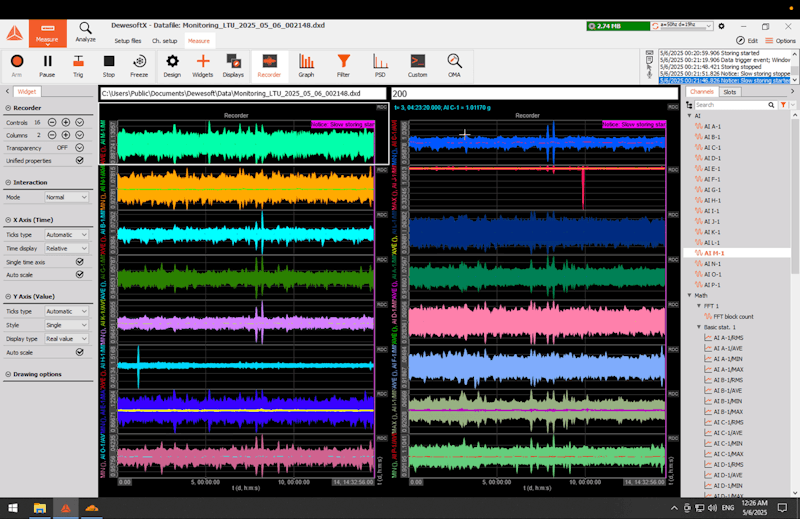

This streamlined network of 16 accelerometers provides a comprehensive picture of how the entire bridge vibrates and moves (See Figure 12: Overhead view of accelerometers). The DAQ collects data from these channels (See Figure 13: Sensors laid out before installation).

The IOLITE 3xMEMS sensors

More specifically, we selected the uniaxial IP67 accelerometer from the IOLITE 3xMEMS sensor family. They are a family of data acquisition devices featuring an embedded triaxial MEMS accelerometer, analog-to-digital conversion, and an EtherCAT interface, all based on the IOLITE modular DAQ device platform.

The Dewesoft IOLITEi 3xMEMS-ACC devices have a very low noise performance. The IOLITEi 3xMEMS-ACC has a 25 µg/√Hz spectral noise density while the IOLITEi 3xMEMS-ACC-S has an ultralow spectral noise density of 0,7 µg/√Hz. It is comparable to the best-in-class Force Balanced accelerometers.

IOLITEi 3xMEMS-ACC are DC response accelerometers, capable of measuring static accelerations starting from 0Hz. Software calculations in DewesoftX enable you to calculate velocity and displacement, as well as static pitch and roll angles, from the DC acceleration values.

The IOLITE 3xMEMS are EtherCAT-based devices and are synchronized down to 1 μs device-to-device. This synchronization is critical when performing Operational Modal Analysis to understand structural dynamics, including natural frequencies, modal shapes, and damping ratios.

Multiple devices can be easily distributed and synchronized over large structures using one inexpensive CAT6 cable that can span up to 100m node-to-node. By using optical converters, distances of more than 20 km can be covered between devices while maintaining a 1 μs synchronization.

The waterproof IP67 enclosure chassis is available for all configurations and can operate in a wide temperature span from -50°C to 65°C.

A standard Ethernet network cable allows devices to daisy-chain. Preferably, a shielded cable (SFTP, CAT5e) having a minimum wire thickness of 24 AWG. The cable must have four wire pairs. The maximum distance between nodes is 100 m, as shown in Figure 14.

A passive PoE (Power over Ethernet) power injector is required to merge the EtherCAT signal and power into a single cable. The IOLITE® power injector is an industrial power injector with embedded burst and surge protection electronics.

The wealth of data generated by this system is processed and made immediately accessible through the powerful DewesoftX software platform. This platform enables engineers and researchers to view sensor data in real-time, observing the bridge's vibrations and responses as they occur (see Figures 11 and 12, which display the DewesoftX interface). This real-time capability is crucial for both immediate monitoring and detailed analysis (See Figure 15).

These accelerometers weren't just about monitoring daily safety; they had a crucial dual purpose for this final phase of the bridge's life and beyond:

Capturing the Bridge's Pulse and Modes: They measure the bridge's global dynamic response – how the entire structure vibrates and moves when subjected to dynamic forces, such as wind, temperature changes, or ambient noise. This data helps engineers understand the bridge's natural frequencies and vibration modes, essentially its structural "fingerprint" in motion.

Informing Future Projects: Engineers use this rich dataset to update and refine the detailed computer models of the bridge created during the assessment phase. Understanding exactly how the bridge behaves is vital information for planning complex operations, such as its demolition. It enables engineers to predict structural responses when removing sections, ensuring a safe and controlled process. Furthermore, the data gathered from this aging, cracked structure provides a unique case study for validating models used to assess and design other bridges in the future.

| Column B | Frequency (Hz) | Figure |

|---|---|---|

| 1 | 1.79 | Figure 17 |

| 2 | 1.858 | Figure 18 |

| 3 | 3.929 | Figure 19 |

| 4 | 4.847 | Figure 20 |

The ‘digital bridges’ initiative

Our work on the Autio bridge is part of a larger, ambitious project aimed at revolutionizing the management of aging infrastructure. Known as the Digital Bridges project (Digital Bridges Project - Luleå tekniska universitet), its goal is to create a holistic platform and system for predictive maintenance and lifecycle management of bridges across Sweden and beyond. This system integrates data from multiple sources, moving beyond traditional inspections to a data-driven approach.

The core concept of the Digital Bridges platform relies on understanding a bridge at three distinct, interconnected levels:

Element Level: This is the most granular level, focusing on data from sensors placed directly on the individual components of the bridge, such as the strain gauges welded onto the rebar (FTG-ARM), accelerometers on the deck, or temperature sensors. This data provides real-time insights into the immediate condition and behavior of specific parts.

Component Level: This level aggregates data and information about the major structural components or the bridge as a whole. It includes traditional sources, such as detailed inspection reports and design drawings, alongside modern tools like the Finite Element Model (FEM), which essentially serves as a digital twin of the bridge. Global structural analyses are performed at this level to understand overall capacity and behavior.

Network Level: This is the highest level, encompassing external factors that impact the bridge's performance and the broader transportation system to which it belongs. This level covers data from sensors on vehicles (such as heavy mining trucks), general traffic data (including volume and patterns), and weather conditions (temperature cycles, precipitation, and extreme events) relevant to the bridge's environment in Northern Sweden.

All this incoming data feeds into the Digital Bridges platform, which serves as the system's central processing unit. Here, intelligent algorithms – using Artificial Intelligence (AI) – sift through the massive amounts of information. AI helps us identify hidden patterns, detect subtle anomalies that traditional inspections may overlook, and even predict how different parts of the bridge may deteriorate over time.

This analysis feeds into crucial outputs for bridge managers:

Bridge Performance Indicators (BPI): These are like the bridge's health report. They translate the raw data and AI analysis into clear metrics showing how well the bridge is currently performing and flagging potential future issues or safety risks. Think of it as turning complex sensor readings into a simple "check engine" light or a detailed diagnostic report.

Circular Economy Integration (CEI): Our platform also evaluates maintenance and repair options not just for structural soundness, but also for their environmental impact. CEI helps us prioritize solutions that extend the bridge's life while minimizing waste, reducing the need for new resource-intensive construction, and promoting sustainable practices. It’s about making the most environmentally conscious decisions over the bridge's entire lifespan.

The Autio bridge serves as an initial step and case study for the Digital Bridges project. Its unique characteristics – an older prestressed design with known cracking issues, subjected to modern heavy loads in a harsh climate, and equipped with extensive instrumentation – make it an ideal test bed for developing and validating our AI models, BPI calculations, and CEI framework. By applying the Digital Bridges framework to Autio, we are learning how to effectively gather, integrate, and analyze data from all three levels for a complex, real-world structure.

This process is crucial for establishing a digital presence in infrastructure management. It means translating the physical reality of structures like the Autio bridge – its cracks, vibrations, and response to traffic and weather – into digital data that our platform can process to provide actionable insights. Understanding the Autio bridge enables us to validate our data pipelines, refine our AI algorithms for predictive analysis, and test the digital twin capabilities (See Figure 21).

Conclusion

The data gathered from Autio's Element-level sensors, combined with its Component-level design data and FEM, and contextualized by Network-level traffic and climate information, helps us build a comprehensive digital picture of its condition and predict its future behavior. This understanding is not only vital for managing the bridge in its final years, but the methods developed here will form the blueprint for integrating thousands of other bridges into the Digital Bridges platform, enabling smarter, more sustainable infrastructure management nationwide.

This critical research and development work is made possible through vital financial support from several key Swedish agencies. We are grateful for the funding provided by the Swedish Transport Administration (Trafikverket) through its FOI-BBT program, as well as contributions from Vinnova under the Strategic Innovation Program InfraSweden's call, which focused on increasing circularity in transport infrastructure.

Additional support comes from the Swedish Agency for Economic and Regional Growth (Tillväxtverket), specifically recognizing our initiative to promote digitization for societal change. Their support underscores the national importance of this project in addressing the challenges of aging infrastructure in a sustainable and technologically advanced manner.

So, as the Autio bridge approaches the end of its service life in 2025, it continues to serve a vital role, providing critical data that will not only help plan its dismantling but also contribute to the broader science and safety of bridge engineering for structures yet to be built. The cracking giant's final act is to become a teacher for the next generation of bridges.

Thanks to groups related to the project