Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Comparing and Evaluating Servo Motor Accuracy, Efficiency, and Thermal Stability

Anamarija Hauptman

University of Ljubljana

November 25, 2025

Servo motors are essential in automation, robotics, and precision control systems, where accuracy, efficiency, and durability are critical. At Ljubljana University, I set out to compare four popular servo motors under both loaded and unloaded conditions using Dewesoft hardware and software tools. By measuring rotation precision, temperature rise, and power consumption, I identified the most suitable motor for demanding engineering applications.

I initially started working on the concept of a humanoid robot head, for which selecting suitable components is a crucial first step. Engineers widely use servo motors in various applications, including automation systems, mechatronics, robotic arms, remote-controlled vehicles, and even educational platforms.

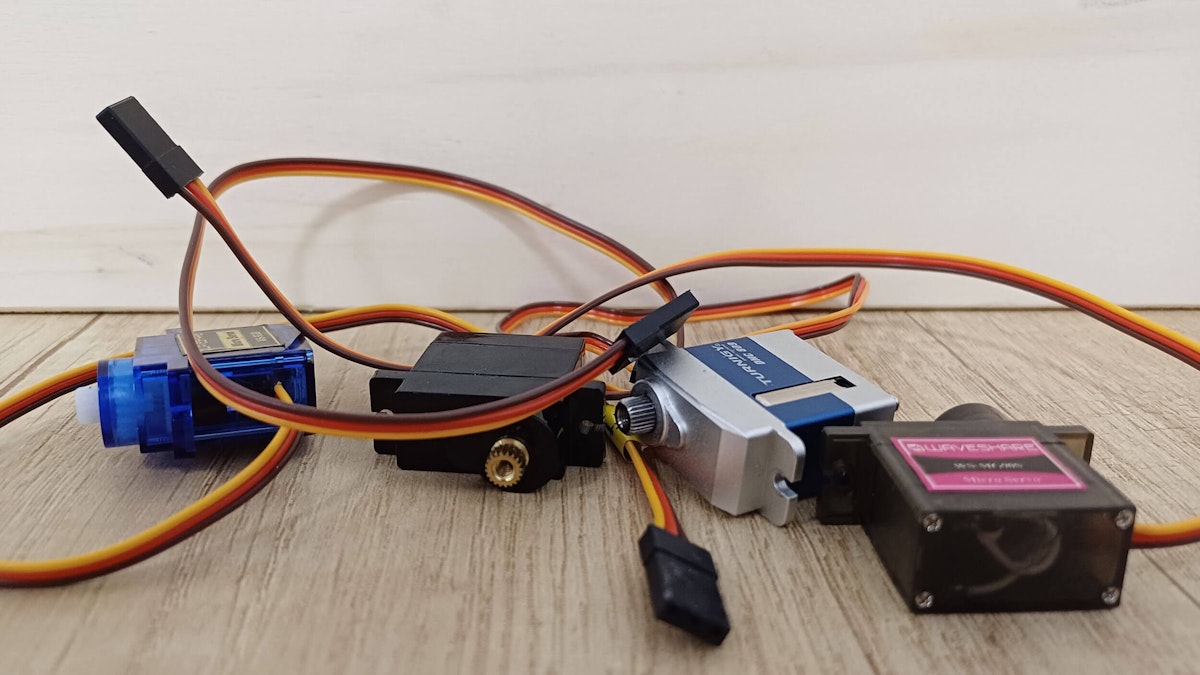

Since motors are among the most essential elements in enabling movement of individual segments, I tested four commonly available servo motors (see Figure 1) to evaluate their performance characteristics under both loaded and unloaded conditions.

Using high-precision Dewesoft measurement equipment and software, I measured motor rotation accuracy, temperature response, and electrical current consumption. These parameters are crucial for assessing motor suitability in terms of efficiency, thermal stability, and control precision.

Tested servo motors for comparison are:

Turnigy DMC 809 (top left)

Waveshare WS-MG90S

Waveshare WS-SG90

Dsservo 9g mg (bottom right).

Measurement chain and procedure

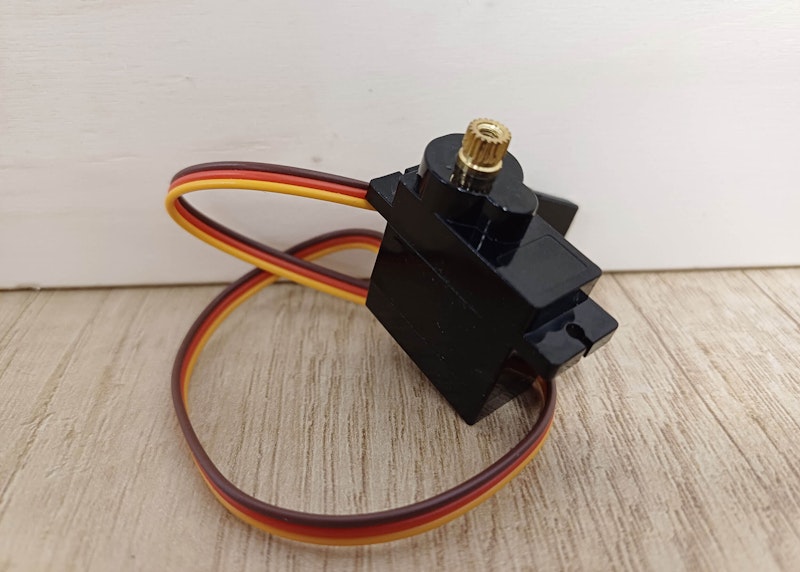

The motors I tested have dimensions of 22 x 12 x 31 mm. I decided to compare them based on the following quantities: motor rotation, electric current flowing through the motor, and motor temperature.

All 12 sensors (three for each motor) were connected to the Krypton, a measuring instrument by Dewesoft. These data acquisition modules are well-suited for distributed measurements, bringing data acquisition closer to sensors. Like all other Dewesoft data acquisition systems, Krypton comes with DewesoftX data acquisition software.

In our case, I used three Krypton modules (see Figure 2), which were interconnected. Two of them have 6 STG inputs, to which I connected adapters for measuring electric current and the encoders. One has 16 TH inputs, to which I connected thermocouples.

I measured motor rotation using the Kalamoyi P3022-V1-CW360 Hall-effect rotation sensor (see Figure 3). It operates on the principle of magnetic field detection and provides an analog voltage output proportional to angular position. I connected it to the KRYPTON-6xSTG DAQ instrument. Figure 4 shows the wiring diagram of the encoder and STG adapter.

To measure the electric current on each motor, I used the Dewesoft DSIi-10A adapter (Figure 5). The measurement range of the adapter is 10 A at a supply voltage of 5 V. Via two banana connectors, I can connect the device under test to the adapter, which in turn connects to the Dewesoft Krypton via the STG input.

I measured the temperature on the motors using type K thermocouples (Figure 6), which operate within a temperature range from −270°C to 400°C.

To drive the motors during testing, I used the Pololu USB servo controller Mini Maestro 24-Channel (Figure 7), which can simultaneously control up to 24 servo motors. Using the Pololu Maestro Control Center software, I was able to send the appropriate commands to the individual channels.

Figure 8 illustrates the connections between all the components.

The complete chain consists of three measuring instruments, a servo controller, a laptop, four servo motors, and for each motor, an encoder, a thermocouple, and an adapter for measuring electric current.

I connected the measuring instruments in series. They have a supply voltage of 24 V, and I powered them with an Axiomet AX-3005DS 0-30V 0-5A power supply. The measuring instruments communicate with the computer via an Ethernet RJ45 connection using DewesoftX software.

An HDR-60-5 transformer powers the servo controller. It communicates with the computer using appropriate software through a USB connection.

I conducted the measurements in two phases. In the first phase, I ran the unloaded motors for one hour, and in the second phase, I loaded them with a torque of 0.083 Nm for the same duration. I loaded the motors by using the clutch, connecting the motor and encoder as a pulley, from which I hung the appropriate weight. During the test, I alternately sent the motors a reference position of rotation from -90 ° to 90°.

Before recording the measurements, I test-ran the motors loaded with half of their maximum torque. During this, the Waveshare WS-MG90S motor failed after approximately 15 minutes, so I immediately excluded it from our comparison.

Results

As already mentioned, I compared the motors based on motor rotation, electric current, and motor temperature.

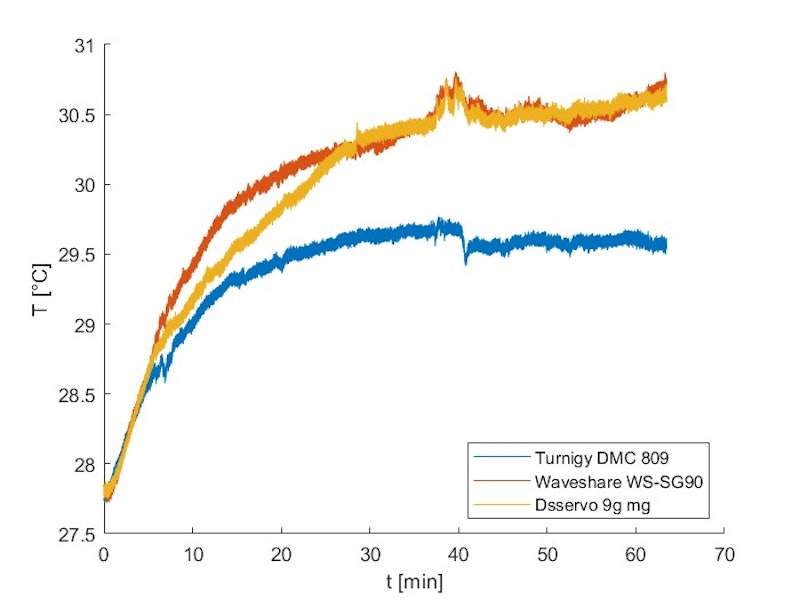

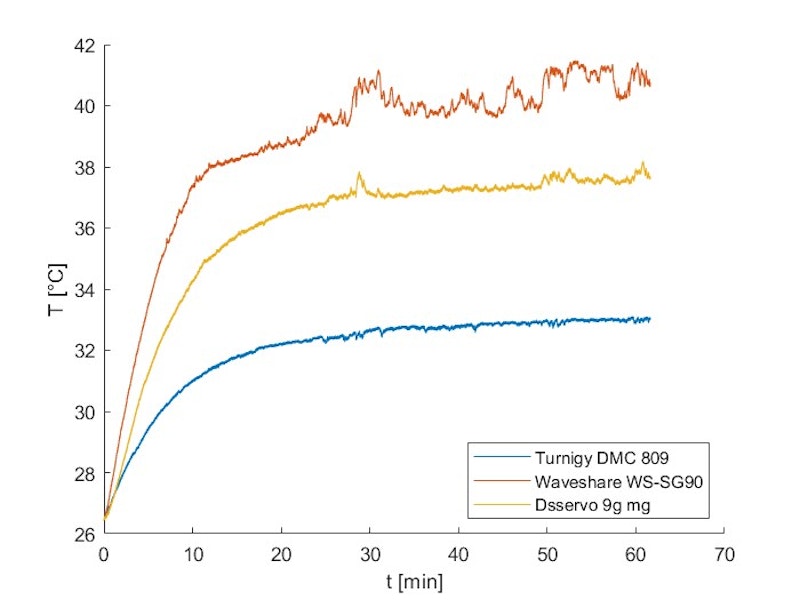

The graphs in Figure 9 show the temperature profiles of the motors over time during operation, separately for operation with and without a load. In the loaded test, the Waveshare WS-SG90 motor heated up the most, reaching temperatures over 40°C. In the unloaded test, the Waveshare WS-SG90 and Dsservo 9g mg motors heated up to approximately the same extent. In both cases, the Turnigy DMC 809 motor heated up the least.

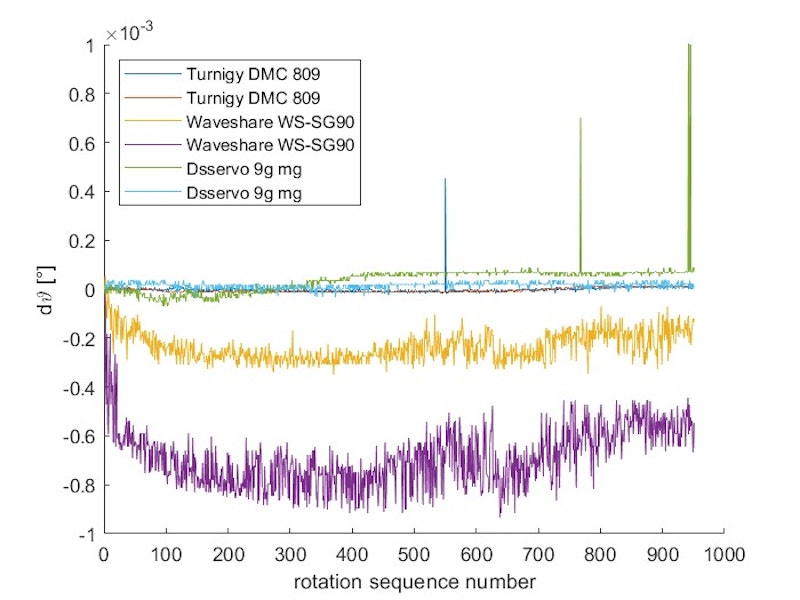

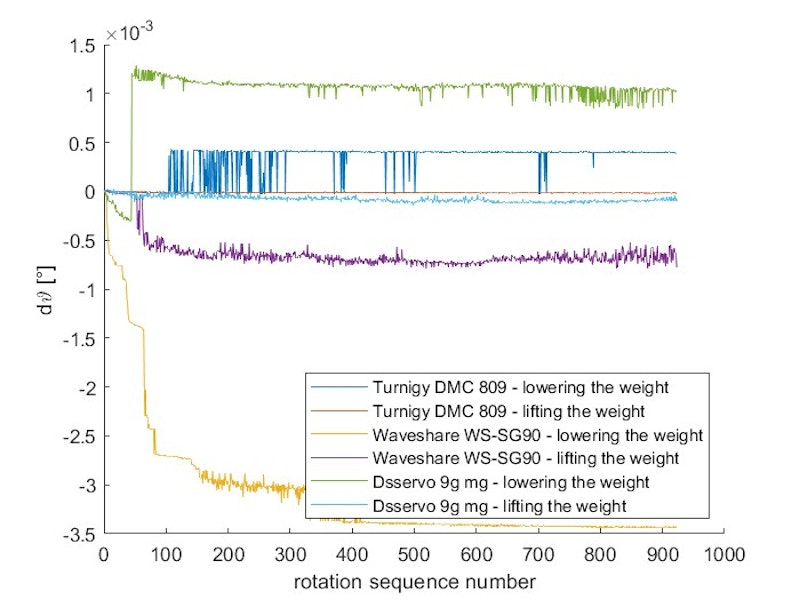

The encoder resolution is 0.0142 V/°. Figure 10 illustrates the angular deviation of the motors from the reference position of ±90° during each rotation.

During unloaded operation, the most significant deviations occurred with the Waveshare WS-SG90 motor, while the Turnigy DMC 809 motor performed the most consistent rotations. Under load, the most considerable deviations also happened with the Waveshare WS-SG90 motor, particularly when lowering the weight. Once again, the Turnigy DMC 809 motor demonstrated the most consistent rotation, particularly in the direction it was lifting the weight.

I measured the internal resistances of the individual motors:

Turnigy DMC 809: R = 17.9 kΩ

Waveshare WS-SG90: R = 18.0 kΩ

Dsservo 9g mg: R = 17.7 kΩ

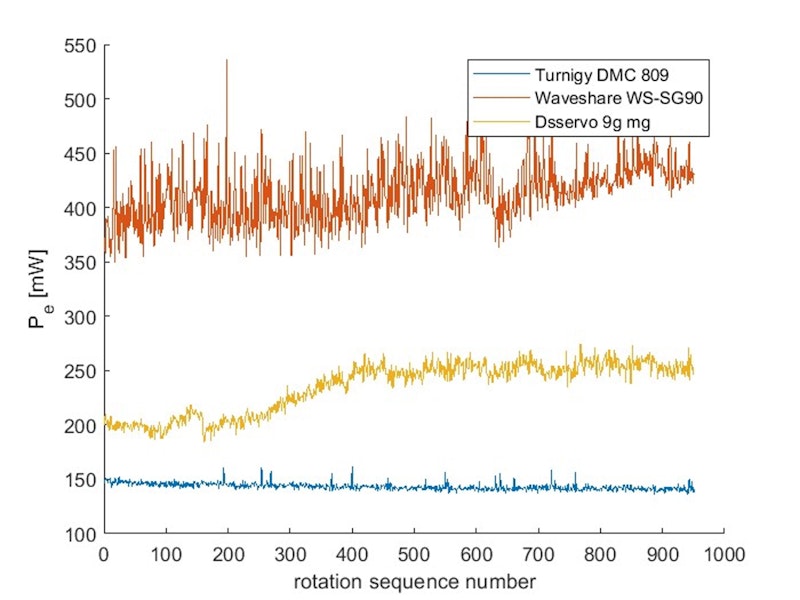

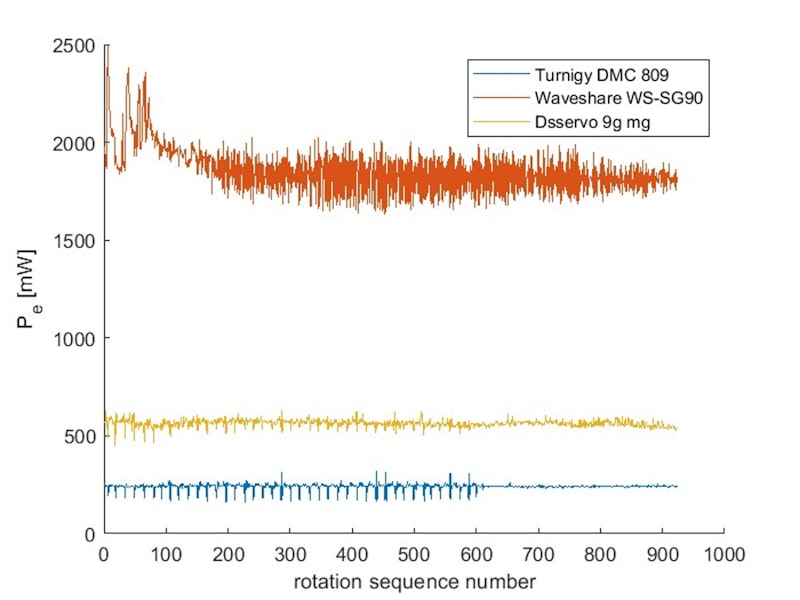

I calculated the average electrical power consumed by the motors during each rotation. Figure 11 shows the electrical power profiles. I can see that, both during unloaded and loaded operation, the Waveshare WS-SG90 motor consumed the most power. On the other hand, the Turnigy DMC 809 motor consumed the least power in both cases.

Conclusion

Our measurements clearly identified the best-performing motor, but the experimental setup also had some limitations. I recorded the temperature on the motor housing, which may not fully reflect the internal winding temperature. I could improve this by placing thermocouples directly on the motor after removing the casing. Similarly, while I accurately measured current and power, I could refine the loading method by using calibrated weights instead of water bottles.

Despite all the possible improvements, based on the results, I concluded that the best motor among the tested ones is the Turnigy DMC 809, as it achieved the most consistent performance across all six measurement parameter categories. It showed the lowest temperature rise during operation, the slightest deviation from the reference rotation angles, and the lowest electrical power consumption, both in the loaded and unloaded tests.

On the other hand, the Waveshare WS-SG90 exhibited the most significant rotation inaccuracies and the highest power consumption, especially under load. These characteristics suggest that it may be suitable for lightweight hobby applications; however, it is less well-suited for tasks that demand precision and durability.