Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

How We Built a Cutting-Edge Vehicle Test Data Acquisition System

October 27, 2025

We needed a fully instrumented automobile to demonstrate our entire range of testing solutions. Here’s how we did it.

Dewesoft manufactures data acquisition (DAQ) systems for a broad range of automotive testing applications. Our instruments can test all kinds of engines, including combustion engines running gasoline, diesel, hydrogen, and ethanol, as well as today’s electric and hybrid-electric engines. We also excel in pass-by noise testing, EMC chamber tests, ADAS (Advanced Driver Assistance Systems), and other important applications.

We have a comprehensive ecosystem of DAQ instruments that can be interconnected and synchronized, and a standard software package called DewesoftX ties them all together. Our credibility is further strengthened by our collaborations with every major brand in the world, including Toyota, Ford, General Motors, Mercedes, BMW, Audi, Volvo and Lamborghini, just to name a few. We work closely with our customers to enhance our product lines and introduce features our customers require.

My name is Matjaž, and I work in the automotive applications group. My job involves working with existing and prospective customers to show how Dewesoft instruments and software can solve their measurement challenges. My colleagues and I visit customers regularly to demonstrate our capabilities and support our products. These tests require:

a detailed setup inside the vehicle,

running wires safely inside and under vehicles,

installing and mounting our instruments and sensors properly, and

setting up the software.

And that’s just the tip of the iceberg! Much effort goes into each one, and each of our customers has specific requirements we need to address. As a result, these installations are very time-consuming.

To address this challenge, we proposed building a “show car” fully equipped with our instruments to demonstrate the powerful and unique capabilities of Dewesoft DAQ instruments.

Choosing the right vehicle

There were a few things to consider when choosing the vehicle that we would work on:

The car should look very nice because it will represent the Dewesoft brand.

It should be a PHEV (plug-in hybrid electric vehicle) with a reasonably big battery, powerful engine, and high total system power. A hybrid-electric car would allow us to showcase our internal combustion and electromotor testing, efficiency, and analysis solutions.

We also wanted a car that would be an excellent “showplace” for our instruments, with plenty of room in the trunk (boot).

We needed easy access to the CAN, CAN FD, Flexray communication buses, and the 60-2 crankshaft sensor used by our combustion analysis module.

We also wanted a car suitable for high-mileage drives around the European Union.

At Dewesoft, we don’t mind mixing a little fun with our business. During our company Christmas party, we talked with management about our idea. They immediately agreed with our desire to assist more customers in less time, increasing our efficiency and helping more customers. With their approval, we started searching for the best possible vehicle.

We had already narrowed the list to a wagon, an SUV, or a BMW with a PHEV drivetrain. Finally, we settled on the BMW because it looked great and had plenty of room for our equipment. It would also be comfortable during long drives and provide a total system power of more than 200 kW and a 400 V 12 kWh battery.

We found an available BMW 330e 2022 with only 5000 km on its odometer. It looked good already, and we were excited to bring it to our workshop.

In addition to ordering an “M3-look” body kit, we asked our marketing department to design a body wrap. They started working on the conceptual design and created some beautiful digital renderings.

The renderings motivated the whole team, and we worked even harder. But a significant deadline loomed on the horizon.

Countdown to MC2024

In early 2024, the company was busy planning the MC2024 measurement conference that would bring more than 600 customers from around the world to Slovenia for three days of technical seminars. The MC2024 was scheduled for the second week of April, and we needed to have our show car ready.

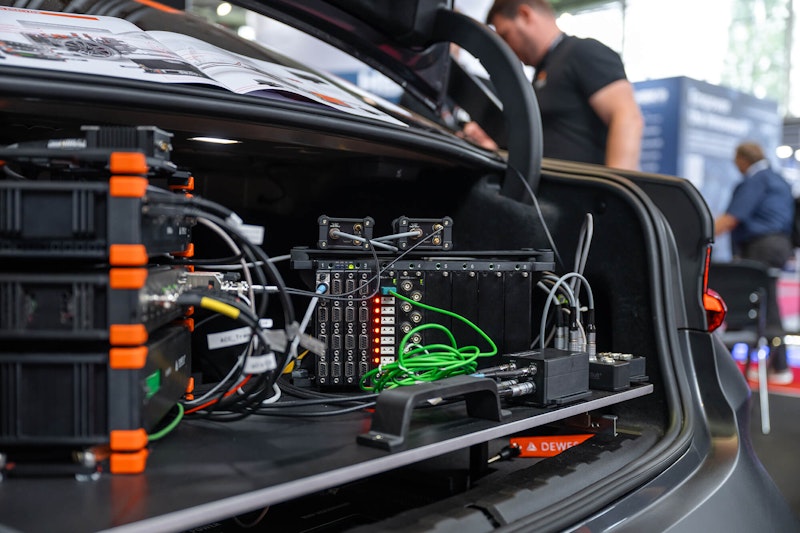

We drew up plans and designs for what we needed to install and how to do it. We identified the ideal instrumentation, cables, and sensors and ordered them. Our sister company, Katapult, started working on a mounting platform with pull-out rails to which the instruments would be fastened in the trunk. Nearly every department in Dewesoft was involved in this project at some point. The deadline grew nearer daily, but we kept our heads down and worked.

Technical challenges

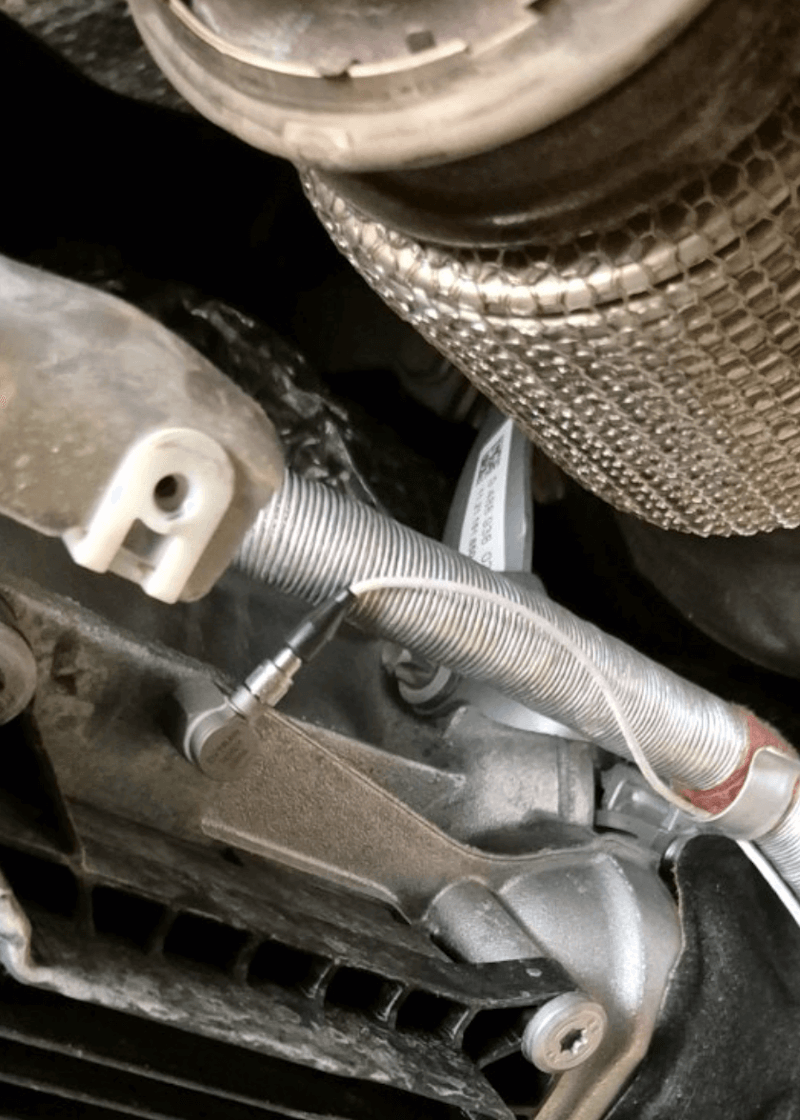

Every engineering product has at least one big challenge, and this one was no different. We needed to extend the high-voltage cable connecting the battery and inverter beneath the car. We investigated this very carefully because modifying any high-power circuit involves human safety. It could also adversely affect the car, so we were determined to do it correctly.

From the beginning, we wanted to avoid having cables in the cabin. This was our show car, and we planned to have customers ride inside while we presented online measurements and calculations on screens for each passenger. Therefore, the cables for all sensors needed to be routed safely and securely.

Because our measuring instruments were to be installed in the trunk, high-voltage cables had to run from the front of the car to the back. We also needed to place strain gauge sensors on the rear axle’s anti-roll bar rocker arms and wireless torque sensors from Easting Electronics onto the rear drive shafts.

We built a sliding table above the orange SIRIUS XHS-PWR (1000 A) shown in the picture above. The XHS-PWR measures high voltage and current with extreme bandwidth and accuracy.

The instruments on the table include (left) a SIRIUS modular high-speed DAQ system with a computer and backup battery system.

Above the SIRIUS stack is a ruggedized KRYTON CAN-FD interface.

On the right side is an OBSIDIAN R8w 8-slot data logger.

A NAVION i2 inertial navigation system is mounted to the right of the yellow handle. The sliding table makes it easy to access the instruments and connectors.

We can change amplifier modules, connect new sensors, and swap the batteries in the backup system below the SIRIUS stack whenever necessary.

The next challenge was running accelerometer cables from the transmission casing and engine block case to the trunk. Those sensors were needed for NVH (noise, vibration, and harshness) order analysis of the vibrations of those two vital drivetrain elements.

Also, from the engine compartment, we needed to run a USB connection for the CAN and FlexRay traffic “sniffing” modules, a thermocouple, and an extension cable for connecting charge-type spark plug pressure sensors that measure in-cylinder pressure, which are also needed for our combustion analyzer.

We obtained a special spark plug with an internal pressure sensor for combustion tests. Finally, we had to run cables from our NAVION i2 inertial navigation system, a microphone in the cabin, an HDMI cable and splitter for driving our in-cabin mobile display screens, and a dash cam that would send live video into our DewesoftX software, synchronized with the data.

We mounted a DS-DISP-15 mobile display on the dashboard for the front-seat passenger to monitor real-time data. We also installed two DS-DISP-13 displays on the back of the front headrests for passengers riding in the rear seats.

After everything was installed and tested, it was time for our baby to leave the garage.

We were invited as special guests to a local “hill climb” event in early June. If you know anything about Slovenia, you know that we are a country with plenty of hills and mountains. This was the perfect opportunity for us to conduct a real stress test of the show car and its instrumentation. We could put the whole system through its paces with full attack and power.

We arranged some on-road tests to ensure that everything was working correctly. We made setups in DewesoftX software to demonstrate our virtual 3D polygon, GPS, INS, video, and map overlay functionality and set up a day of drive testing. We made multiple test runs, each one pushing the envelope. The show car and all our instrumentation and setups worked perfectly, and there were big smiles and high-fives from the spectators and our whole team. Here is a replay of one of the test runs that we made.

Finally, it was April, and engineers were arriving for the MC2024. Thankfully, the show car was ready!

The attendees' reaction was terrific. We were already setting up one-on-one customer visits across Europe, particularly in countries with significant car manufacturing centers like Germany, Sweden, France, Italy, etc. During MC2024, I was happy to give a short presentation of the show car to our marketing team, which you can watch below.

In June, we took our new show car to Germany for Testing Expo 2024 in Stuttgart, and we got the same fantastic response from automotive engineers from all around the world.

Creating our show car was a lot of work, but we solved each problem step by step. This project perfectly demonstrated how our entire company could focus like a laser with teamwork, powered by lots of coffee and not a few Red Bulls. 🙂

The DEMO car also demonstrates the power of Dewesoft instruments, offering a range of options for comprehensive vehicle testing.

The Dewesoft application support team is ready to support our customers in every industry, including automotive, aerospace, industrial, energy, condition monitoring, structural monitoring, and more.