Table of contents

Browse categories

Browse authors

AL

ALAlessia Longo

AH

AHAl Hoge

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

e-NVH Testing: Combining Electric Power and NVH Analysis

October 9, 2025

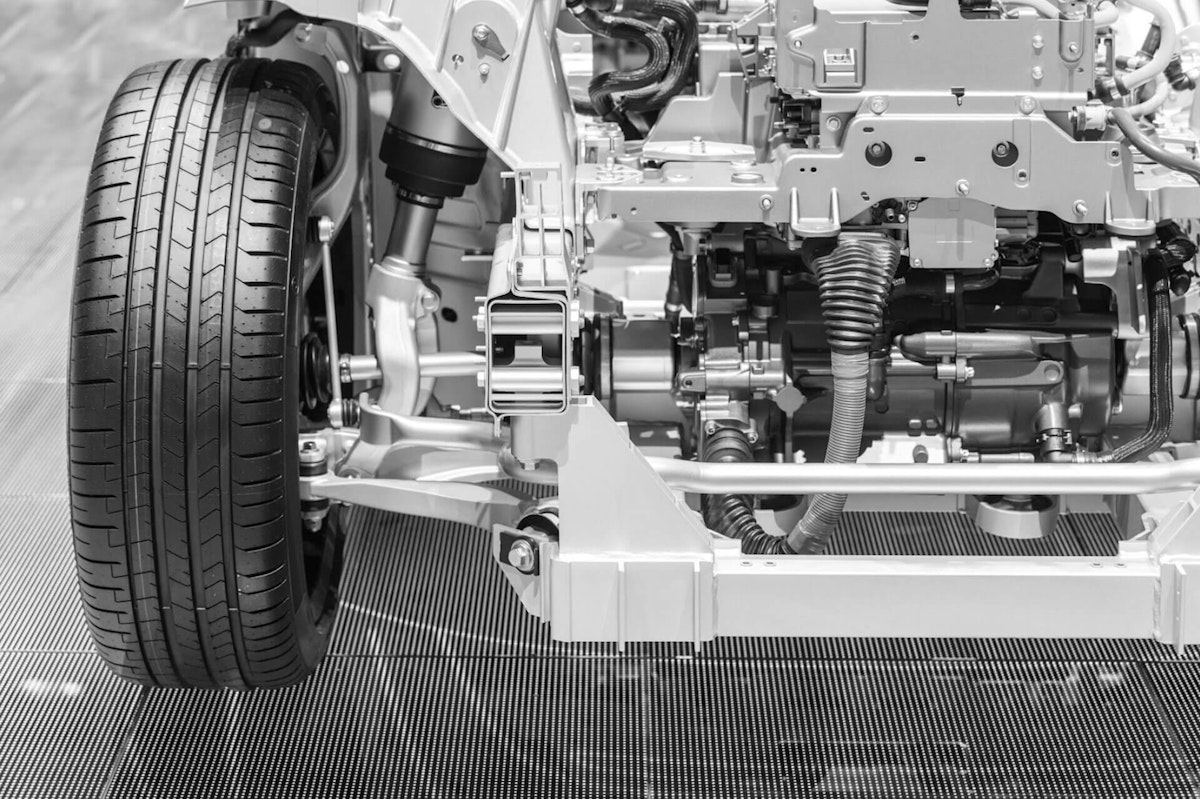

It is common practice to consider testing domains, such as electric power and NVH (noise, vibration, and harshness), as separate entities. However, the combination of these domains is crucial for simulation and prototype testing. In fact, “multiphysics” testing bridges the gap between theory and real-world performance. This integrated approach enables engineers to predict, validate, test, and optimize electric drives, such as traction motors and electric axles, with unprecedented accuracy and efficiency.

What is e-NVH?

e-NVH (electric Noise, Vibration, and Harshness) is the study and measurement of noise and vibration phenomena associated with electric powertrains, such as motors, inverters, and gearboxes. It combines traditional NVH techniques with electric power analysis to identify and optimize sources of unwanted sound and vibration in electric vehicles and machines.

This multidisciplinary approach is essential for improving performance, comfort, and perceived quality in modern electric mobility systems. This article describes how e-NVH is performed and its advantages.

Bridging the gap between design and reality

One of the greatest strengths of combining simulation with physical testing is its ability to bridge the gap between design and reality.

During the early stages of product development, simulation tools can predict e‑NVH behavior and power losses by modeling phenomena such as electromagnetic forces in permanent magnet synchronous motors (PMSMs) or inverter switching noise.

However, physical testing remains indispensable for validating these predictions and uncovering effects that are not fully captured in simulation, such as variations introduced by manufacturing tolerances or material inconsistencies. For instance, an e‑motor simulation may predict low vibration levels. However, real‑world testing can expose unexpected resonances caused by slight variations in housing stiffness—issues that would remain hidden without empirical data.

This integrated approach also yields direct time and cost savings. Simulation allows NVH engineers to rapidly iterate on design choices, such as optimizing stator skewing or refining pulse‑width modulation strategies, well before hardware prototypes are built. Once physical components have been created, testing them with data acquisition platforms such as SIRIUS, using DewesoftX software, provides the empirical data needed to fine-tune designs and ensure compliance with performance and regulatory targets.

Many engineers, for example, use simulation tools such as COMSOL, Altair Flux, and ANSYS Maxwell to create predictive models, then validate them and optimize their prototypes by making real-world measurements using SIRIUS-based e-NVH and power analysis instruments.

Common e-NVH challenges & mitigations

Despite the numerous advantages of integrating electric power and NVH analysis into a unified e-NVH workflow, several challenges are frequently encountered during testing and simulation that should be addressed to ensure reliable results.

High-frequency electromagnetic noise

Modern traction motors and inverters often operate at high switching frequencies, generating electromagnetic interference (EMI) that can contaminate both electrical and acoustic measurements. This is particularly problematic when measuring subtle NVH signals such as tonal whines or casing vibrations.

Mitigation: High-quality signal conditioning, including isolated inputs, differential sensing, and proper cable shielding, is essential. Dewesoft SIRIUS modules, for example, feature galvanic isolation, automatic anti-aliasing filtering, and high dynamic range inputs that reduce susceptibility to common-mode noise, EMI, and signal aliasing.

Synchronization across domains

e-NVH analysis requires a precise correlation between time-domain signals from multiple domains, including electrical, mechanical, and acoustic. Even millisecond-level drift between these channels can obscure the root causes of vibration or noise.

Mitigation: Hardware-level synchronization using common time bases (e.g., GPS, IRIG, and PTP V2) and deterministic sampling across all DAQ modules ensures alignment of signals across domains. Any of these methods can be used to synchronize SIRIUS XHS modules.

Modeling Assumptions vs. real-world variability

Simulation models often assume ideal boundary conditions and uniform material properties. In practice, however, slight manufacturing variations such as rotor imbalance or stator misalignment can have a significant impact on vibration and noise.

Mitigation: Real-world testing should be used to validate and refine models. Correlating simulated outputs, such as radial force waves, with measured vibration and sound pressure level data enhances model fidelity and reduces the number of design iteration cycles.

Capturing transient events

Many noise and vibration phenomena, such as gear lash or torque ripple, are transient and occur under specific operating conditions (e.g., acceleration, regenerative braking). These may be missed during steady-state measurements.

Mitigation: High-speed, event-triggered acquisition with sufficient pre- and post-trigger buffers helps capture short-duration events. Real-world tests using high-speed mobile DAQ platforms, such as SIRIUS XHS, are ideal for this purpose.

Data volume and complexity

e-NVH testing generates large volumes of high-resolution, multi-domain data. This creates challenges in terms of storage, processing, and interpretation.

Mitigation: The use of integrated software platforms, such as DewesoftX, simplifies data handling by storing all synchronized data in a single file format. Automated analysis routines and real-time dashboards further streamline the interpretation and reporting process.

By proactively addressing these challenges through robust DAQ hardware, synchronized acquisition, validated simulation, and intelligent software workflows, engineers can maximize the accuracy and efficiency of their e-NVH testing programs, achieving faster time-to-market and more refined product performance.

Use cases for e‑NVH

Unlike internal combustion engines, which produce a wide range of mechanical and acoustic sources of noise, the noise and vibration in electric drives introduce new and often subtler sources of vibration and sound, making e-NVH analysis essential. The applications of e‑NVH testing extend far beyond motor whine analysis. It is routinely used in:

EV Drivetrain Testing: Identifying inverter‑induced tonal noise and harmonics in electric motors.

Electric Axle Development: Correlating efficiency maps with acoustic noise and vibration, and structural vibration

Battery Cooling Systems: Measuring pump‑induced vibrations and associated tonal noise.

Aerospace and Drone Applications (eVTOL’s): Linking inverter switching frequencies to propeller acoustic emissions.

These examples demonstrate how integrating electrical, acoustic, and vibrational domains enables engineers to diagnose issues that would be time-consuming to identify using separate measurement workflows.

Relevant case studies:

Diagnosing complex, multidisciplinary problems

Beyond validation, this combination of methods plays a critical role in diagnosing complex, multidisciplinary problems. Electrical frequency analysis can reveal anomalies such as current harmonics or unbalanced loads. At the same time, simultaneous e-NVH testing links these electrical phenomena to audible noise or mechanical vibration, as in identifying a 48th-order whine in an electric vehicle caused by stator slot harmonics.

In some cases, what appears to be a mechanical fault—such as excessive propeller vibration in a drone—can, through FFT analysis, be traced back to inverter‑induced torque ripple, highlighting the value of an integrated diagnostic approach.

Order tracking is particularly essential in this context. By mapping noise and vibration to motor orders, gear meshing frequencies, and even to inverter switching harmonics, engineers can quickly identify root causes and implement design changes that target the true source of undesirable phenomena.

DewesoftX order analysis module enables order-tracked demodulated processing according to the inverter switching frequency, allowing for direct investigation of inverter-induced harmonic effects, even online while the machine is running. You can perform such online analysis, for example, by adjusting the speeds, temperature, and torque loads, as well as by utilizing a variable switching frequency.

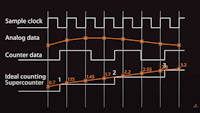

SuperCounters for order tracking

Rotational angle data is required for the order-tracked calculations, and this can be obtained by measuring an analog tacho pulse signal, but this method has limited angle precision. A better solution is SuperCounter® technology from Dewesoft. SuperCounters provide ultra-precise angle reference information, enabling exact correlation between rotational orders and vibration/noise measurements, even at very low rotational speeds.

Learn more:

Multiphysics optimization: simulation meets reality

The combination of simulation and testing also enables multiphysics optimization. Advanced modeling platforms allow the coupling of electromagnetic, structural, and acoustic domains to optimize component design holistically.

Physical testing then provides the real-world data needed to calibrate these models, improving their predictive accuracy by incorporating empirically derived damping ratios, electromagnetic noise, vibration, and other electromagnetic interference (EMI) effects, as well as other relevant parameters.

Tesla, for instance, is known to simulate radial force waves to minimize motor housing vibration, then verify the results with physical measurements. This process combines virtual and real-world insights for optimal performance.

Finally, this integrated workflow underpins modern predictive maintenance strategies and AI‑driven analytics. Continuous monitoring of electrical signals and vibration—collected by current sensors, accelerometers, and other instrumentation—can feed live data into digital twin models. These models then use trend analysis of NVH and power signatures to estimate remaining useful life and predict impending failures.

For example, some suppliers apply Motor Current Signature Analysis (MCSA) in conjunction with vibration monitoring to anticipate bearing degradation in wind turbines, enabling proactive maintenance that reduces downtime and lifecycle costs.

Compliance with standards

To ensure traceability and comparability, e-NVH testing often aligns with international standards, such as:

| Standard | Domain | Dewesoft Module |

|---|---|---|

| ISO 9614-1 / 9614-2 | Sound Intensity | Sound Intensity Module |

| ISO 7779:2010 | Prominence Ratio | Sound Quality Module |

| ISO 3744 / 3745 / 6395 / 6396 | Sound Power | Sound Power Module |

| ISO 532-1 / 532-2 | Psychoacoustic Loudness | Psychoacoustics in Sound Quality Module |

| IEC 61672 | Sound Level Measurement | Sound Level Meter |

| ISO 2631 / 5349 / 8041 | Human Body Vibration | Human Body Vibration Module |

| ISO 20816 | Rotating Machinery Vibration | Order Tracking & Torsional and Rotational Vibration Module |

| IEC 61000-4-7 | Harmonic Measurement | Power Quality Module |

| IEC 61000-4-30 | Power Quality | Power Quality Module |

| ISO 16750 | Vehicle Electrical/Electronic Testing | Power Quality Module |

| SAE J1715 | EV Propulsion Noise | Order Tracking & Sound Level Meter, FFT Module |

| VDA 303 | Brake Noise Testing | Brake Noise Testing |

Workflow for e‑NVH testing

A typical e‑NVH testing workflow combines simulation, prototype testing, and multiphysics data fusion:

Simulation and pre-design: Utilizing platforms such as ANSYS Maxwell or COMSOL to model magnetic forces, inverter switching noise, and structural vibration responses.

Prototyping and integrated testing: Capturing synchronized acoustic, vibration, and electrical data using SIRIUS and other Dewesoft DAQ hardware and DewesoftX software.

Data fusion and analysis: Applying order tracking, sound intensity mapping, power quality analysis, and efficiency mapping within DewesoftX to generate actionable insights.

Correlation and optimization: Comparing simulation predictions with real‑world measurements to refine models and make informed design changes. For example, simulation tools can predict radiated noise from electric motors; however, only real-world measurements—such as vibration and sound pressure levels—can validate these predictions with confidence.

Digital twin and predictive maintenance: Feeding combined multiphysics datasets into digital twin frameworks for lifecycle monitoring and predictive maintenance.

This unified process ensures that real‑world behaviors are captured early and incorporated into the design stage loop, enabling “first‑time‑right” designs and reducing costly iterations.

A unified DAQ ecosystem

Dewesoft DAQ instruments, such as the SIRIUS and SIRIUS XHS line, are available in various form factors, ranging from highly portable 8-channel modules to larger instruments integrated with a computer and display. As such, they are equally at home on a dyno test bench and performing real-drive tests in a vehicle.

All Dewesoft DAQ instruments can be interconnected and synchronized, forming a cohesive ecosystem. This significantly reduces hardware costs and ensures that all instruments are interoperable, allowing them to be exchanged as needed.

This unified DAQ ecosystem also reduces training costs and prevents operational errors. It eliminates the need for multiple independent systems (each with an additional learning curve), eliminates time‑consuming data merging, and streamlines training by standardizing on a single software platform.

An integrated DAQ software solution

Dewesoft’s e-NVH systems are based on a single software application: DewesoftX. Investment costs are reduced by limiting the need for separate software licenses and ongoing software maintenance fees. The base software package is included at no cost with Dewesoft DAQ hardware, and updates and upgrades are free of charge for the life of the system. Specific advanced modules, such as the power quality analyzer, are paid options; however, they are also supported with free updates and upgrades for the life of the system.

By employing a single, versatile DAQ system rather than multiple specialized systems, the overall testing architecture becomes less complex, and all acquired data is stored in a unified file format, eliminating the time-consuming task of merging data from disparate sources.

This consolidation can also lead to shorter development cycles, as integrating one DAQ system is far easier than managing several. It also reduces training requirements by allowing staff to learn a single software platform, DewesoftX. The same platform can then serve multiple applications.

With fewer instruments to calibrate and no software maintenance costs, maintenance expenses are kept to a minimum. Furthermore, simplifying the toolchain reduces the number of potential support issues while maintaining high data quality and full functionality. In some cases, this approach even reduces the number of specialists required for testing, as experts in areas such as eNVH or electric drives can be cross-trained to work effectively across disciplines.

For end users, DewesoftX DAQ software provides a streamlined and intuitive experience within a single software environment that accommodates a wide range of testing scenarios. The platform supports multiple users, enabling collaboration across teams while minimizing the number of software packages that need to be learned, thereby significantly reducing complexity. By keeping all data in a single, time-synchronized file, the need for exporting, converting, or merging is eliminated, enabling much faster and more efficient data exchange between experts in different domains.

Conclusion

By combining electric powertrain analysis with e-NVH evaluation in a unified multi-physics NVH simulation environment, engineers can significantly reduce the number of physical prototypes required during the development process. When this approach is paired with extensive multi-physics testing—ideally performed within a single, integrated ecosystem—it ensures that critical real-world behaviors are captured without introducing unnecessary complexity to the workflow.

The close correlation of simulation and measurement enables a “first‑time‑right” design process, accelerating development time while meeting all key performance attributes. Multiphysics testing, deployed across both simulation and real‑world testing, is now a cornerstone of achieving optimal performance, efficiency, and user satisfaction in modern electric drive systems.

Common FAQs

1. What exactly is “e-NVH” testing?

A combined measurement of electrical (power) and NVH (noise, vibration, harshness) phenomena on electric drives, time synchronized for multi-domain analysis.

2. How does e-NVH differ from traditional NVH?

Traditional NVH focuses solely on mechanical/acoustic outputs, whereas e-NVH links those outputs back to electrical signals (e.g., inverter switching currents).

3. Why are SuperCounters essential for order tracking?

They provide ultra-precise angle reference information, enabling exact correlation between rotational orders and vibration/noise measurements, even at very low speeds.

4. Which simulation platforms support e-NVH workflows?

Standard tools include COMSOL Multiphysics, ANSYS Maxwell with System Coupling, and Altair Flux, which offer electromagnetic-structural or electro-acoustic coupling modules.

5. How do you calibrate a simulation model with real-world test data?

By importing measured damping ratios, stiffness values, mode shapes, and EMI signatures from prototype tests into your multiphysics model, you can refine boundary conditions and material properties.

6. What DAQ hardware is required for e-NVH?

At a minimum, these include multi-channel power analyzers, accelerometers, microphones, a high-speed tachometer (or SuperCounter), and a synchronized DAQ system, such as SIRIUS.

7. How do you set up time synchronization across multiple sensors?

Use EtherCAT or another deterministic bus to distribute a common clock to all modules, and verify synchronization with a simultaneous trigger or known test signal.

8. What is order-tracking, and why is it important?

Order-tracking maps vibrations or noise to the harmonics of rotational speed (orders), allowing for the identification of specific sources, such as gear mesh or slot harmonics.

9. Can I retrofit e-NVH testing onto an existing driveline test bench?

Yes, by adding synchronously triggered DAQ channels (e.g., Dewesoft SuperCounters), mounting accelerometers and microphones at best-practice locations, and integrating your existing power analyzer.

10. Which international standards govern e-NVH measurements?

Key ones include ISO 9614 (sound intensity), ISO 3744 (sound power), ISO 2631 (human body vibration), and IEC 61000-4-7 (electrical harmonics).

11. How does e-NVH feed into digital-twin and predictive-maintenance strategies?

Live e-NVH signatures can update your twin’s acoustic and vibrational submodels and drive algorithms that forecast remaining useful life based on trend deviations.

12. What ROI can I expect from implementing e-NVH early in development?

Requiring fewer prototype iterations leads directly to savings of time and money, and profitability is always enhanced by increased customer satisfaction.