SIRIUS® XHS 4xHV, 4xLV

3-Phase Power Analyzer

Dewesoft solutions for battery testing scale effortlessly to your needs—from individual cells to full battery packs, from electrical measurements to complete multi-physics and multi-attributes analysis. Our tools deliver precise insights at every level of Energy Storage System (ESS) testing.

With Dewesoft, you can safely measure and analyze key attributes such as electrical power and efficiency (input, internal, output), thermal behavior (sensing or camera), structural durability (strain), and vibration for modal and operational analysis. We also support misuse and abuse testing, along with full digital vehicle bus integration (CAN FD, xCP, CHAdeMO, ...)—all within one intuitive software platform.

For even deeper analysis, our advanced Electrochemical Impedance Spectroscopy (EIS) feature completes the package, providing everything needed for comprehensive battery analysis in a unified, powerful ecosystem.

Safe and precise measurement of high-voltage signals (up to 2000V) and high-current loads.

Dewesoft DAQ system are modular and expandable from single-cell all the way up to and full-pack testing.

Capture fast transients and high-speed events with sampling rates up to 15 MS/s per channel.

SIRUS® XHS power analyzers offer 5 MHz bandwidth acquisition and analysis with up to 15 MS/s sampling rate per channel.

The "worry-free" solution provides isolation on the sensor side (channel-to-ground), channel-to-channel, and even isolated sensor excitation. Experience less noise, no ground loops, and the best signal quality.

Simultaneous recording of electrical, thermal, mechanical, and environmental parameters with perfect time synchronization with a single instrument.

Real-time calculation of power parameters, efficiency and loss calculations, charge/discharge analysis, and full DC and AC power measurement.

Dewesoft offers direct logging and communication of CAN, CAN FD, XCP and EtherCAT protocols which allow for full BMS validation.

Dewesoft DAQ systems support a long-list of features and communication protocols to make them smoothly integrated into the test benches.

Deffesoft can read and program ECU’s directly from the Dewesoft measurement system via integrated XCP capabilities.

High-isolation temperature measurement amplifiers for precise thermal analysis in high-voltage environments.

IEPE, MEMS, and charge accelerometer support for in-depth vibration analysis and modal testing.

Connect any force, strain, and displacement sensors to perform structural integrity testing.

Easily expandable from single-cell testing to full battery pack validation, supporting laboratory and field testing applications.

Dewesoft supports ISO, UN 38.3, IEC 62660, and other global battery testing standards.

Plug-and-play channels setup, intuitive drag-and-drop interface, customizable screens, reporting, advanced power analysis, and other math tools.

The DewesoftX oftware package is always evolving and new features are being added. We offer lifetime FREE software updates and technical support to all our users.

Enjoy our industry-leading 7-year warranty. Our data acquisition systems are made in Europe, utilizing only the highest build quality standards. We offer free and customer-focused technical support. Your investment into the Dewesoft solutions is protected for years ahead.

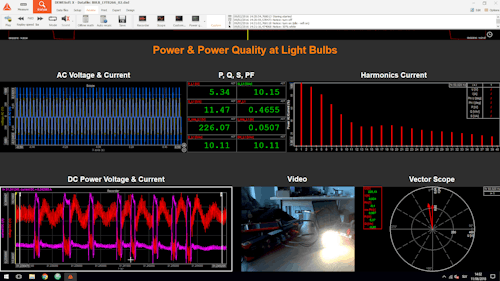

Measure and analyze harmonics for voltage, current, and total harmonic distortion (THD) at frequencies up to 150 kHz, in accordance with the guidelines outlined in the IEC-61000-4-7 standard.

And we're confident you'll love it too! But don't just take our word for it. Get hands-on with a demo unit, completely free of charge. No strings attached, just real data. Reach out to your local Dewesoft team and get your demo unit now!

It includes everything you need for advanced data acquisition and common signal processing — no maintenance fees, no contracts. You buy it, you own it. All future updates? Free forever. And the best part? Analysis seats are unlimited and free. Once the data is recorded, anyone can download our software to review and analyze your data — no license needed.

Dewesoft is 100% owned by employees who believe in what we do — and love doing it. We’re in this with heart, passion, and long-term commitment. What does that mean for you? Our core value — caring for our customers — isn’t going anywhere. We’re here for the next 100 years, protected from outside acquisitions. Your investment in our technology is safe, supported, and future-proof.

At Dewesoft, quality isn't just a promise — it's a core value. Our products are 100% designed, developed, and manufactured in-house, right in the heart of the European Union. From precision machining and PCB manufacturing to final assembly and software development — we do it all ourselves, to the highest ISO standards. We're proud to support local production and take social responsibility seriously.

At Dewesoft, quality is more than just a word — it's a commitment. That's why our products come with an industry-leading 7-year warranty. It's just one more way we protect your investment and give you peace of mind for the long run.

Battery testing presents several challenges as OEMs, battery manufacturers, and cell suppliers strive to develop high-performance, reliable, and safe battery systems for electric vehicles (EVs) and energy storage applications. With increasing demands for higher energy density, longer range, and faster charging, testing solutions must be precise, scalable, and adaptable to new technologies.

One of the primary challenges is ensuring accurate and reliable measurement of voltage, current, and capacity across various battery cells and packs. Since battery behavior varies under different operating conditions, test systems must capture real-time data under dynamic load scenarios while maintaining high accuracy. Additionally, high-voltage and high-current measurement requires safe and isolated data acquisition to prevent electrical hazards and ensure compliance with industry safety standards.

Another major challenge is integrating multiple testing disciplines—batteries must be evaluated not only for electrical performance but also for mechanical durability, vibration resistance, and thermal stability. This requires synchronized testing across power analysis, thermal imaging, strain measurement, and environmental simulation to detect potential failures before deployment. Furthermore, as battery technologies evolve, testing solutions must be scalable and future-proof, supporting next-generation battery chemistries, solid-state batteries, and new energy storage architectures.

Dewesoft addresses these challenges by offering high-precision, modular, and integrated battery testing solutions, ensuring comprehensive validation for the next generation of battery-powered systems.

Dewesoft offers highly accurate data acquisition systems which are essential in several battery testing applications.

High-precision charge and discharge testing - accurate measurement of voltage, current, and power during battery charging and discharging cycles.

Efficiency and loss mapping - real-time efficiency calculations under different loads and energy balance monitoring.

Identification of energy losses and heat dissipation.

State of Charge (SoC) and State of Health (SoH) Analysis.

Long-term monitoring of battery degradation.

Measurement of internal resistance and capacity fade over time.

Dewesoft’s HV-compatible power analyzers allow safe and accurate measurement of high-voltage battery packs in EVs.

Harmonics, interharmonics and THD analysis.

DC and AC impedance testing - evaluation of battery impedance under different load conditions to optimize design and performance..

High-speed transient analysis - capturing rapid voltage and current fluctuations in dynamic load changes.

BMS communication and validation - real-time monitoring of BMS data via CAN, CAN FD, XCP, or EtherCAT.

Synchronization of voltage, current, and temperature sensors with BMS data.

Cell balancing and monitoring

Verification of battery cell balancing strategies to ensure equal charge distribution.

Thermal runaway and overcurrent protection testing - correlation of thermal imaging, temperature sensors, and power measurement for safety validation.

Vibration and shock testing - simultaneous mechanical and electrical stress testing for automotive and aerospace applications.

Environmental Testing - battery performance analysis under different temperature, humidity, and altitude conditions.

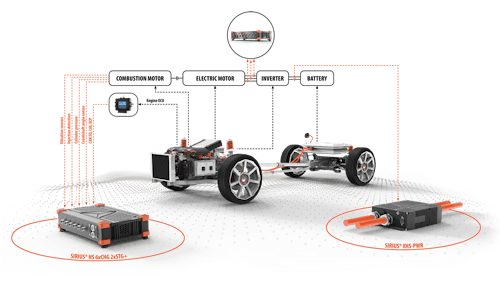

Complete EV powertrain testing - combining battery, inverter, and motor testing for full e-mobility powertrain validation.

Synchronization with GPS, vehicle speed, and real-world driving conditions.

Grid and energy storage testing - analysis of stationary battery systems, renewable energy storage, and grid applications.

Dewesoft’s integrated testing solutions allow for simultaneous monitoring of multi-physics quantities:

Mechanical (structural, vibration, etc.)

Electrical (power, energy, harmonics, efficiency)

Thermal

This holistic approach enables a comprehensive understanding of your test specimens under various conditions. Our user-friendly software DAQ systems makes it extremely easy to configure different inputs and facilitate real-time data visualization and analysis. This streamlines the entire testing process and observe conditions from all angles.

By choosing Dewesoft, you ensure that your products are rigorously tested to withstand the conditions they need to operate in.

Thermal runaway needs to be prevented. Ensure safety and compliance in high-voltage traction battery systems with cutting-edge short-circuit testing solutions. From precisely measuring a few amps to recording explosive current surges, our solution handles it all. Our advanced measurement setup enables you to qualify battery packs and their circuit breakers like pyro fuses under extreme conditions. Capture electrical current transient peaks in the kiloamp range with ultra-high sampling rates and unmatched accuracy. Designed to withstand high voltage, fast rise times, and harsh EMI environments, our system offers full isolation, overvoltage protection, and superior EMC performance.

Easy to use DewesoftX software for complete setup, sequence it, set trigger, calculate overall energy, visualize all signal data including camera, replay data, compare and report.

Safe, 15 MS/s/channel high-speed voltage and el. current measurement.

Camera integration (high-speed, infrared, or web cam).

Multi physics measurement: voltage, current, temperature, digital inputs.

Vehicle bus logging (CAN, CAN FD, LIN, XCP, FlexRay, etc.)

Dewesoft consultancy and training.

IEC 62660-2:201: This standard specifies test procedures to evaluate the reliability and abuse behavior of secondary lithium-ion cells and cell blocks used in the propulsion of electric vehicles, including battery electric vehicles (BEV) and hybrid electric vehicles (HEV).

IEC 63056:2020: Pertaining to energy storage systems, IEC 63056:2020 outlines product safety requirements and testing for secondary batteries and battery systems used in energy storage applications with a maximum DC voltage of 1500 V (nominal).

UN 38.3: This standard addresses the testing requirements for lithium batteries transported by air, including external short circuit tests to simulate potential short circuit scenarios during transit

Dewesoft power meters offer numerous benefits compared to conventional power analyzers. They provide a highly flexible solution for electrical and mechanical power measurements, combined with power quality analysis capabilities, making them the perfect choice for comprehensive power analysis.

Key Advantages:

Multi-Functional Device: Dewesodt power analyzers combine the functionality of a power analyzer, combustion analyzer, oscilloscope, raw data logger, spectrum analyzer, and CAN logger in a single device.

Synchronous Data Acquisition: Captures electrical, mechanical, vehicle bus, positioning data, and video simultaneously.

Unified Data Storage: Stores all data in one system and one data file format.

Integrated Power Analysis and Data Storage: Allows combined power analysis and raw data storage.

Real-Time Calculation: Performs live, online power calculations with 1ms resolution.

Enhanced Power Quality Analysis: Advanced tools for thorough power quality assessments are provided.

Versatile Input Channels: Supports any number and type of input channels, including voltage, current, IEPE/ICP, strain, thermocouple, RTD, and CAN.

Portable and Modular System: Our portable power analyzers are battery-powered and feature an integrated LED display, a fast CPU, and SSD storage, making them fully portable and standalone. Modular systems can easily be distributed and offer convenient setup for test benches and lab use. All power analyzers are expandable to hundreds of I/O channels.

Sensor Software Calibration: Includes additional software calibration for sensors.

Integrated Sensor Power Supply: We provide power for sensors such as current transducers directly from our power analyzers, eliminating the need for an external sensor excitation source.

These features make the Dewesoft powers analyzer a comprehensive and efficient power analysis solution, eliminating data synchronization, visualization, storage, and comparison issues.

Accurate efficiency and loss analysis is crucial in battery testing, ensuring optimal performance and reliability. Dewesoft power analyzers and data acquisition systems provide high-precision DC and AC measurements to evaluate battery efficiency, charge/discharge cycles, power losses, and overall energy conversion.

Battery performance and power efficiency testing involves a range of important key attributes:

Capacity: The amount of charge a battery can store and deliver, typically measured in milliampere-hours (mAh) or ampere-hours (Ah).

Voltage: The electrical potential difference between two points in a battery. Voltage is critical in determining whether a battery is fully charged, discharged, or malfunctioning.

Current: The flow of electrical charge, usually measured in amperes (A). Battery testing often includes current measurement during charge and discharge cycles.

Cycle Life: The number of charge and discharge cycles a battery can undergo before its capacity degrades to a certain level, often 80% of its original capacity.

State of Charge (SOC): A measure of the current charge in a battery relative to its total capacity, typically represented as a percentage.

State of Health (SOH): A measure of the overall condition of a battery, including its ability to hold charge and deliver power relative to its original specifications.

Internal Resistance: The resistance within a battery that impedes the flow of current. Higher internal resistance can indicate aging or poor performance.

Charge/Discharge Rate: The speed at which a battery is charged or discharged, often expressed as C-rate (e.g., 1C, 0.5C).

Coulombic Efficiency: The ratio of the amount of charge a battery can deliver during discharge to the amount it received during charging. It measures the efficiency of the charge/discharge process.

Temperature / thermal integrity: Temperature can affect battery performance, efficiency, safety, and life. High temperatures can accelerate degradation, while low temperatures can reduce capacity. Worst case scenario is a so called “thermal runaway”

Power Density: The amount of power a battery can deliver per unit of mass or volume, usually measured in W/kg or W/L.

Energy Density: The amount of energy stored per unit mass or volume, typically measured in Wh/kg or Wh/L.

Voltage Drop: A decrease in battery voltage under load. This can indicate a problem like excessive resistance or over-discharge.

Charge/Discharge Efficiency: How efficiently a battery converts input energy during charging and how much usable energy it delivers during discharge.

Overcharge/Overdischarge: Charging or discharging a battery beyond its safe limits can damage it, leading to reduced lifespan or safety risks.

Impedance Spectroscopy: A method for measuring and analyzing the impedance of a battery across a range of frequencies. It helps in understanding the battery's internal properties and health.

Safety Compliance Testing: Tests conducted to check for issues like short-circuiting, thermal runaway, leakage, and overvoltage that could cause hazards during battery use.

Knowing these terms provide a comprehensive understanding of a battery's performance, longevity, and safety.

While battery testing primarily involves DC analysis, hybrid and electric powertrains also rely on inverters and electric motors, where three-phase AC analysis is essential.

Dewesoft power analyzers support both DC and AC testing, including motor and inverter efficiency analysis and performance evaluation. Using Park-Clarke transformations, our systems provide deep insights into vector-controlled AC motors and power electronics, helping engineers optimize entire energy conversion systems in electric and hybrid vehicles.

Our data acquisition hardware supports DC and AC measurements directly. Mutliple 3-phase AC systems and DC systems can be measured at the same time, giving you a troughout view of you energy flow. Support for any wiring type is supported: single phase, 3-phase star, 3-phase Aron, 3-phase delta, etc.

With real-time data acquisition, and high-resolution data, Dewesoft delivers a complete solution for testing and optimizing battery performance, efficiency, and powertrain components.

To learn more on this please visit our Electric vechicle testing page.

Battery charging plays a crucial role in the performance, efficiency, and longevity of any battery-powered device. Dewesoft power analyzers and data acquisition systems provide a comprehensive solution for testing and analyzing both AC and DC charging processes, ensuring precise efficiency evaluation, power quality assessment, and charging time optimization.

Dewesoft systems enable detailed monitoring and analysis of:

AC & DC charging performance

Charging energy consumption and efficiency

Charge/discharge cycle analysis

Charging process timing and optimization

Power quality and harmonics analysis

Wireless charging technology requires precise high-frequency analysis for optimal power transfer. Dewesoft solutions support:

High switching frequency measurements (up to 150 kHz)

Efficiency analysis for power transfer up to 6 kW (60-80%)

Dewesoft power analyzers are powered by award-winning datya acquisition software that provides a wide range of analytical tools for deep insights into the charging process:

Real-time charging process visualization

Scope, FFT, 3D FFT, Reference FFT

Harmonic analysis and FFT (2 kHz – 150 kHz) for power quality assessment

Harmonic table for detailed frequency domain analysis

Voltage commutation, unbalance, and in-rush current detection

Accurate charging power calculation and display widgets

Dewesoft's high-resolution data acquisition, real-time analysis, and intuitive visualization, enables comprehensive testing of both conventional and inductive EV battery charging. Our solutions help engineers optimize energy transfer, reduce losses, and improve charging efficiency.

Effective thermal management is crucial for ensuring battery performance, longevity, and safety. Dewesoft data acquisition systems provide precise temperature monitoring and thermal analysis, enabling engineers to assess heat generation, dissipation, and overall thermal integrity under various operating conditions.

For battery thermal integrity testing, Dewesoft systems support:

Multi-point temperature measurements using thermocouples, RTDs, and infrared sensors

High-isolated thermocouple amplifiers, specifically designed for high-voltage (HV) environments, ensuring safe and accurate temperature measurements

Real-time monitoring of heat distribution across battery cells and modules

Thermal runaway detection to ensure safe operation

Correlation of temperature with electrical and mechanical performance for efficiency optimization

Environmental chamber testing to evaluate performance under extreme conditions

By integrating synchronized electrical and thermal measurements, Dewesoft solutions allow engineers to identify thermal inefficiencies, improve cooling strategies, and prevent overheating risks. The modular and scalable DAQ system architecture ensures that high-speed, high-resolution data is captured accurately, making it an ideal solution for battery thermal integrity testing in electric and hybrid vehicles.

Batteries must perform reliably under extreme temperatures, humidity, and pressure conditions to ensure safety and efficiency in real-world applications. Dewesoft DAQ systems provide precise monitoring and analysis during environmental chamber testing, enabling engineers to evaluate battery behavior in controlled test environments.

For battery environmental testing, Dewesoft systems support:

Multi-point temperature, humidity, and pressure measurements using high-precision sensors

High-isolated thermocouple amplifiers, designed for high-voltage (HV) environments, ensuring accurate thermal monitoring in harsh conditions

Real-time performance tracking under varying environmental stresses

Synchronized electrical, thermal, and mechanical analysis to assess performance degradation

Advanced, yet easy-to-use data analysis and reporting tools

Dewesoft’s data acquisition ensures comprehensive monitoring of battery durability, efficiency, and safety across a wide range of environmental conditions. With high-resolution measurements and advanced analysis tools, our solution provides deep insights into battery performance during temperature cycling, humidity exposure, and extreme environmental stress testing.

Electrochemical Impedance Spectroscopy (EIS) is a powerful technique used to analyze the electrochemical properties of battery systems. By applying a small alternating current (AC) signal over a range of frequencies, EIS measures the impedance response, providing insights into various internal processes such as charge transfer resistance, double-layer capacitance, and diffusion characteristics. This information is crucial for understanding battery health, efficiency, and lifespan.

Dewesoft’s EIS testing capabilities

Dewesoft offers advanced data acquisition systems capable of performing precise EIS measurements. Our solutions enable:

High-Frequency Impedance Measurements: Capture detailed impedance spectra over a wide frequency range to analyze electrochemical processes accurately.

Real-Time Data Processing: Utilize DewesoftX software for immediate visualization and analysis of impedance data, facilitating prompt decision-making.

Comprehensive Analysis Tools: Employ equivalent circuit modeling and parameter fitting to interpret complex impedance data effectively.

For a practical application of our EIS testing capabilities, refer to our case study on electrolysis stacks: Electrochemical Impedance Spectroscopy Measurements on Electrolysis Stacks.

By integrating Dewesoft’s EIS testing solutions, researchers and engineers can gain valuable insights into battery performance, leading to optimized designs and improved reliability.

Learn more on our Electrochemical Impedance Spectroscopy (EIS) testing page.

Batteries in electric and hybrid vehicles must withstand mechanical stress, vibrations, and impacts to ensure safety, reliability, and longevity. Dewesoft data acquisition systems provide high-precision testing solutions for evaluating mechanical and structural durability in both real-world and laboratory conditions.

For battery mechanical testing, Dewesoft systems support:

Road-to-rig testing – Capturing real-world vibration, shock, and impact data from vehicles and replicating it in lab conditions

Shaker and 6DOF (six degrees of freedom) testing – Simulating operational vibrations and multi-axis load conditions

Accelerometer and strain gauge measurements – Monitoring structural integrity and fatigue under mechanical stress

Synchronized electrical and mechanical analysis – Correlating vibration effects with battery performance and efficiency

Fatigue and failure analysis – Identifying weak points to improve battery enclosure design

With high-speed, multi-physics data acquisition, Dewesoft solutions enable engineers to evaluate battery robustness, optimize structural design, and ensure compliance with safety standards in automotive, aerospace, and industrial applications.

Battery systems in electric and hybrid vehicles are subjected to continuous mechanical vibrations and shocks during operation. This can impact their performance, durability, and safety. To ensure reliability, it’s essential to conduct comprehensive vibration testing that simulates real-world conditions. Dewesoft offers advanced solutions tailored for battery vibration testing, providing precise measurement and analysis to meet the rigorous demands of modern battery systems.

Dewesoft’s high-performance data acquisition systems can capture detailed vibration profiles across a wide frequency range. Our systems support all vibration sensor types, including IEPE, MEMS, and charge accelerometers, ensuring compatibility with different testing requirements. Our equipment has a great signal-to-noise ratio of over 130 dB and a dynamic range of up to 160 dB. This means it provides accurate and reliable data, which is essential for detailed vibration analysis.

Dewesot’s modal testing and analysis capabilities allow engineers to determine the natural frequencies, mode shapes, and damping characteristics of battery enclosures and structural components. Identifying and mitigating potential resonance issues prevents mechanical failures and extends battery lifespan.

Learn more about Dewesoft modal testing and analysis solutions.

Learn more about Dewesoft Vibration testing solutons.

A Battery Management System (BMS) is critical for monitoring, protecting, and optimizing battery performance. Ensuring accuracy and reliability of the BMS requires comprehensive testing of its voltage, current, temperature, communication, and balancing functions. Dewesoft data acquisition systems provide a complete solution for testing BMS functionality in real-world conditions.

For BMS testing, Dewesoft systems support:

High-precision voltage and current monitoring across individual cells and modules

Temperature measurement with high-isolated thermocouple amplifiers, ensuring safe operation in high-voltage (HV) environments

Cell balancing analysis to verify BMS efficiency in charge equalization

Real-time CAN, CAN FD, XCP, and other protocol decoding for communication testing

State of Charge (SoC) and State of Health (SoH) evaluation for battery condition monitoring

Fault detection and logging to analyze BMS response under stress conditions

With synchronized electrical, thermal, and communication data acquisition, Dewesoft enables engineers to validate BMS algorithms, detect inefficiencies, and ensure optimal battery operation. The system’s scalability and high-speed data acquisition make it ideal for research, development, and validation of BMS in electric and hybrid vehicle applications.

Many regulatory tests require a unified data acquisition platform that integrates battery parameters, testbench signals, and ECU control strategies for documentation and reporting. Dewesoft can integrate with both seamlessly.

Battery testing often requires logging ECU data via CAN, CAN FD, FlexRay, or XCP/CCP protocols. This allows engineers to correlate battery performance metrics with vehicle control data, such as powertrain efficiency, charging algorithms, and thermal management strategies. Deffesoft can read and program ECU’s directly from the Dewesoft measurement system. Our advanced XCP communication protocol offers an easy way to communicate with Vehicle’s ECU.

Dewesoft can also integrate and communicate seamlessly with the battery testbench controller. Our DAQ systems can send and receive data from battery cyclers and environmental chambers, enabling automated charge/discharge cycles, durability tests, and safety validations.

Laboratory tests alone are not enough to fully understand battery performance under real-world conditions. Dewesoft portable power analyzers and DAQ systems provide high-precision data acquisition for on-road EV battery testing, ensuring accurate assessment of true driving range, efficiency, and energy consumption in dynamic environments.

Key features for real-world battery testing:

Portable and rugged design of DAQ hardware for in-vehicle testing in any conditions

Wide operating temperature range (-40°C to +85°C) for extreme conditions

Real-time measurement of power, energy consumption, and efficiency

True range assessment under actual driving conditions (WLTP, WLTC, etc.)

High-accuracy voltage and current monitoring for charge/discharge cycles

Integrated GPS and vehicle data logging for complete test analysis

Dewesoft systems allow engineers to capture precise powertrain performance data while vehicles operate under various driving scenarios, terrains, and climate conditions. With synchronized data acquisition and real-time analysis, our solution ensures a comprehensive understanding of EV battery performance, helping optimize efficiency and extend driving range.

See and browse related and compatible data acquisition products.

3-Phase Power Analyzer

1-phase power analyzer with integrated DC-CT® current transducer

Portable Power Analyzers

EtherCAT Data Acquisition and Real-Time Control System

Data logger and embedded data acquisition system

The best AC⚡DC current sensor available today!

High-Accuracy Sensors for Current Measurement

Award-Winning Data Acquisition and Digital Signal Processing Software

See and browse related and compatible testing solutions.

Synchronized voltage and current acquisition for battery impedance testing

Power and efficiency testing of electric motor and inverter

High-precision electrical power measurement and analysis [AC⚡DC]

High-precision power quality measurement and analysis

Complete testing solutions for electric and hybrid vehicles

Complete power analysis and power quality testing solution

Thermocouple, RTD, and thermistor data recording

Voltage and high-voltage data recording

Wind, solar, and geothermal energy testing

Scaling power analysis from component to complete micro grid

Aircraft Flight Control Systems Test