Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Dewesoft X3 SP10 Released

May 15, 2024

Dewesoft starts 2020 with a release of a new Dewesoft X3 SP10.

The update expands Dewesoft’s structural analysis solution with a fully-fledged sine reduction/sine processing test functionality. The customers in the aerospace industry will be happy to hear that the SIRIUS PCM-FS2 can now also be used as a simulator/encoder with the help of a firmware upgrade. Finally, the generalization of gear tooth with missing teeth sensors is a unique feature on the market which makes the Dewesoft’s combustion engine analyzer module even more attractive.

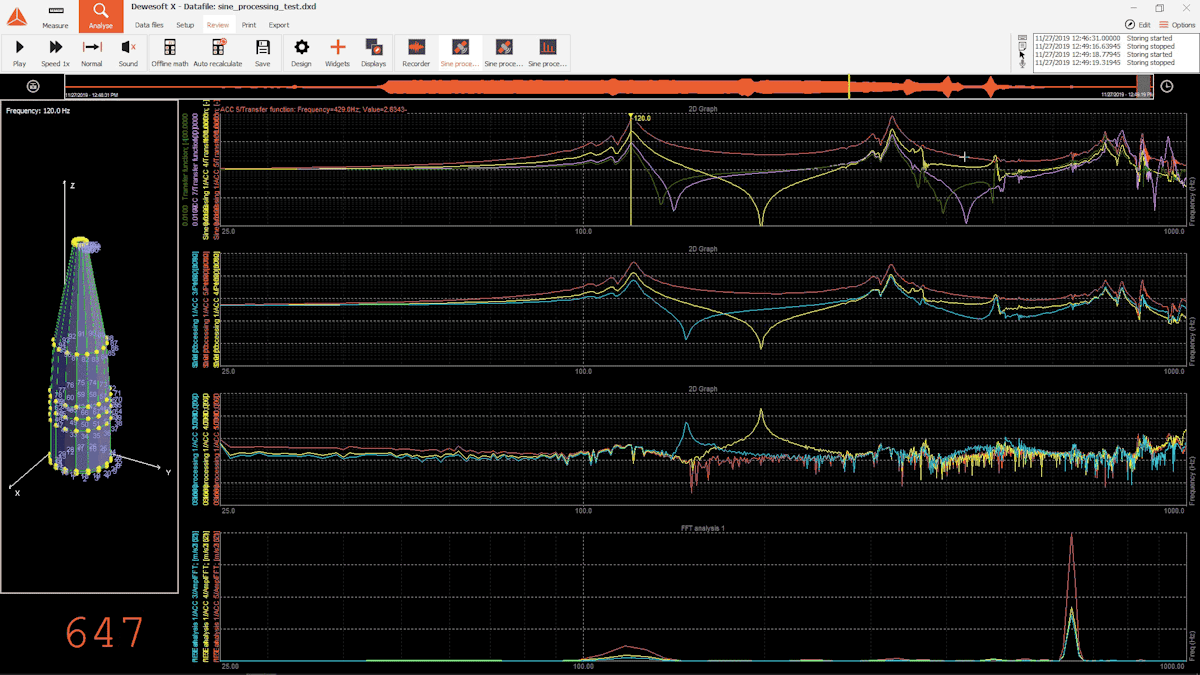

Sine reduction test - sine processing with COLA signal

Sine processing is a tool used for performing structural tests on large structures. It allows users to identify and analyze natural frequencies of such structures by exciting them with a sweep of single frequencies that are being tracked by Dewesoft’s software module, using a COLA signal from a vibration shaker controller.

As desired output, Sine processing returns:

the structural resonance

frequencies,

amplitudes,

phase,

THD of response and also

transfer functions between excitation and response points.

With the addition of the sine reduction/sine processing module to Dewesoft X3 data acquisition software has become one of the most powerful structural analysis tools, supporting the evaluation of responses and transfer functions on an unlimited number of channels, all done in real-time online, making it a valuable tool for manufacturers, designers, and engineers.

Sine processing is a licensed module that can be purchased as an upgrade on new or existing Dewesoft X licenses.

For more information please see:

Aerospace telemetry: PCM output (PCM encoder and simulator)

Dewesoft has always had the ability to acquire and synchronize a magnitude of different types of signals like analog, GPS, IRIG time, 1553, video, ARINC 429 and many others.

In the world of telemetry, however, it is often required that all of that data is encoded and transmitted as a PCM stream. Up to now, Dewesoft relied on third-party hardware for this task, but this is no longer the case with an upgrade to the SIRIUS PCM-FS2.

The firmware and software updates allow all types of channels to be encoded into a PCM data stream online, thus creating the perfect solution for a flexible and scalable PCM Encoder system. This solution helps users in a variety of ways, from easily creating a PCM stream over trying out new sensor configurations, to simulating a vehicle on the launch pad without tying up expensive flight hardware.

This capability can also be used to correlate and record the stray analog signals from receiver AGC strengths to the communication links in the ground station. Additionally, a Simulator functionality to replay Chapter 10 files from the hard drive of a computer or a fixed major frame simulator is also available.

The PCM output functionality is a licensed feature that needs to be purchased as a license upgrade.

Generalization of gear tooth with missing teeth sensors

Dewesoft can now provide one of the first systems on the market that supports any stock sensor with missing teeth on the engine, which makes using the Combustion Analyzer or other NVH applications even easier and more effective since no additional sensors need to be installed for crank angle position detection.

This is possible because Dewesoft’s support for gear tooth with missing teeth sensors has been expanded to include almost every imaginable configuration. It is now possible to use a sensor with an arbitrary number of gaps at completely arbitrary positions around the gear, the only conditions being that all teeth still need to have the same width and that the widths of gaps are expressible in terms of the number of missing teeth. The concept for a new sensor mode came from engine manufacturers who need asymmetric crank-angle sensors on the crankshaft, as they allow them to know the exact position of the shaft before a full engine revolution is complete.

The feature is available as standard on every counter input without additional license fees.

As always Dewesoft X3 is a free upgrade for all existing Dewesoft customers. You can download the Dewesoft X3 SP10 release from our download center, where you will also find a changelog listing all the minor improvements and bug fixes.