Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Monitoring the Durability of Timber Gantry

Institute of Timber Engineering and Wood Technology (LIGNUM), Graz University of Technology

November 21, 2024

‘Green’ sign gantries on highways are the concept of a joint Austrian business and research project to reduce the carbon footprint. In the Green Gantry Project, the structure of combined timber, metal, and adhesive materials, exposed to wind and weather, is now tested to ensure strength and durability. Dewesoft helped measure strains and the resulting forces within the structure.

Everyone knows the grey gantries on the highway. Usually made of steel, the gantries carry signs, displays, cameras, or sensors. Kapsch TrafficCom and the Institute of Timber Engineering and Wood Technology at Graz University of Technology have now developed a ‘Green Gantry’ made of timber to reduce these gantries' carbon footprint.

Lignum test center (LTC)

Kapsch TrafficCom is hosting the project and taking care of the technical equipment in general. Funded by the Waldfonds, an initiative of the Austrian Federal Ministry of Agriculture, Forestry, Regions, and Water Management, the project runs for three years. It is part of the Austrian Wood initiative’s ‘Think.Wood program’ including the research partners:

The Institute of Timber Engineering and Wood Technology (LIGNUM, Graz University of Technology)

The HASSLACHER Group, and

Denkstatt GmbH.

The Graz University of Technology’s Lignum Test Center (LTC) took over the task of equipping the wooden prototype with sensors and installing a Dewesoft monitoring system.

Materials long-term Interaction

Within the research project, two major scientific topics are of interest:

Material fatigue: Wind and traffic induce dynamic loads on the structure. Concerning timber engineering, a knowledge gap is present in the material fatigue field, especially for connections.

Moisture-induced stresses: Moisture can cause stresses in timber through swelling and shrinking. These stresses become more pronounced when metal fasteners restrict the deformation. In extreme cases, the resulting stresses lead to cracks in the wood and can potentially even lead to the yielding of the metal fastener.

Monitoring setup

Long-term monitoring was necessary to underline the theoretical modelling within the research project with proper data. For this, TU Graz needed data acquisition equipment:

SIRIUSi-HD-16xSTGS - universal data acquisition module with USB interface and internal quarter/half bridge completions for measuring strain gages

2 x DEWE-43A - universal data acquisition module with USB interface, TU Graz had the bridge completions done externally

Sync cables - to ensure all modules are running with the same clock - learn more about synchronization here

DewesoftX software - measurement and analysis software package included with the hardware; software updates are free

the triggered storing options were beneficial for this project

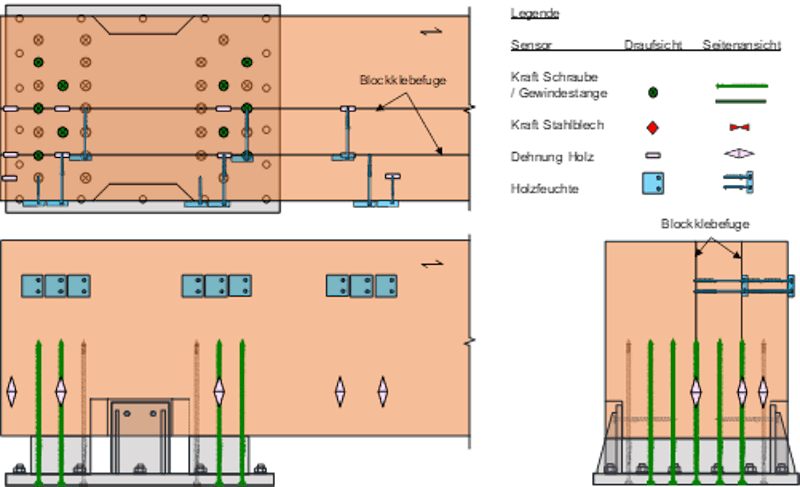

TU Graz was in the project from the beginning. Already in production, the team divided the timber beam into three parts to embed the sensors in three different depths from the surface: 60, 120, and 240 mm. After the sensor application, the parts were block-glued to the final cross-section.

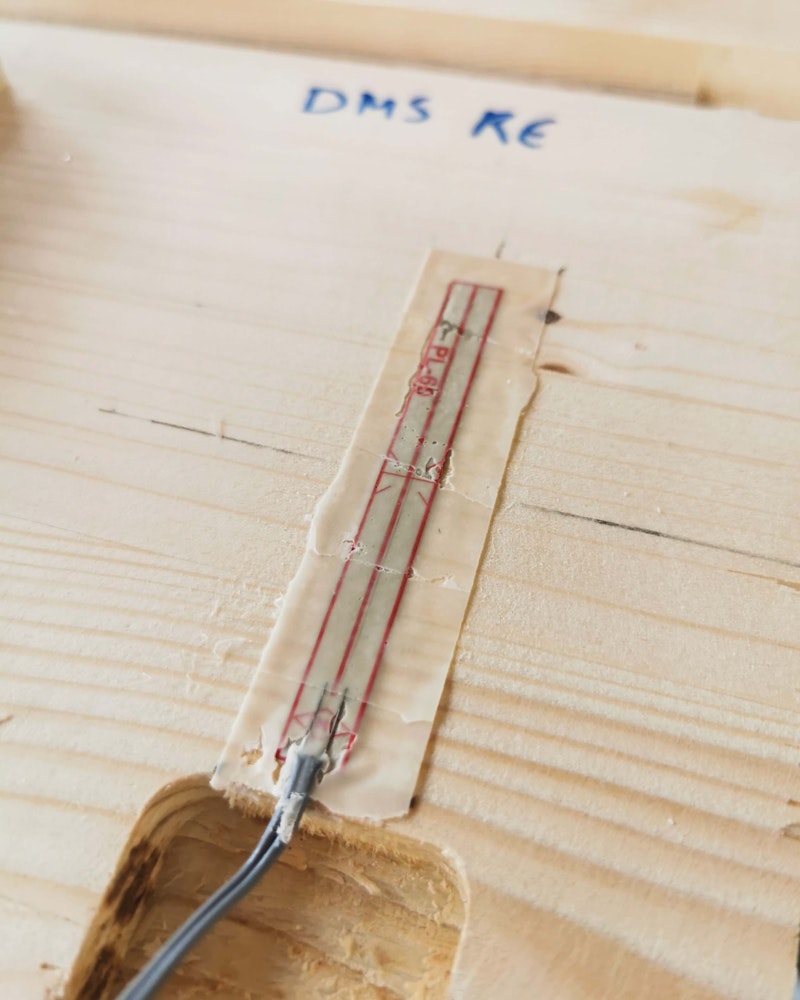

The team mounted most sensors within the beam’s cross-section, mainly in the frame corner and some in one of the columns, resulting in cable lengths of around 5 to 10 meters per sensor. For proper cable routing, it milled slots into the timber. The strain gauges were sealed with a specific rubber to protect against humidity. Eleven humidity sensors were mounted in the three different and previously mentioned depths to measure the moisture content of the timber.

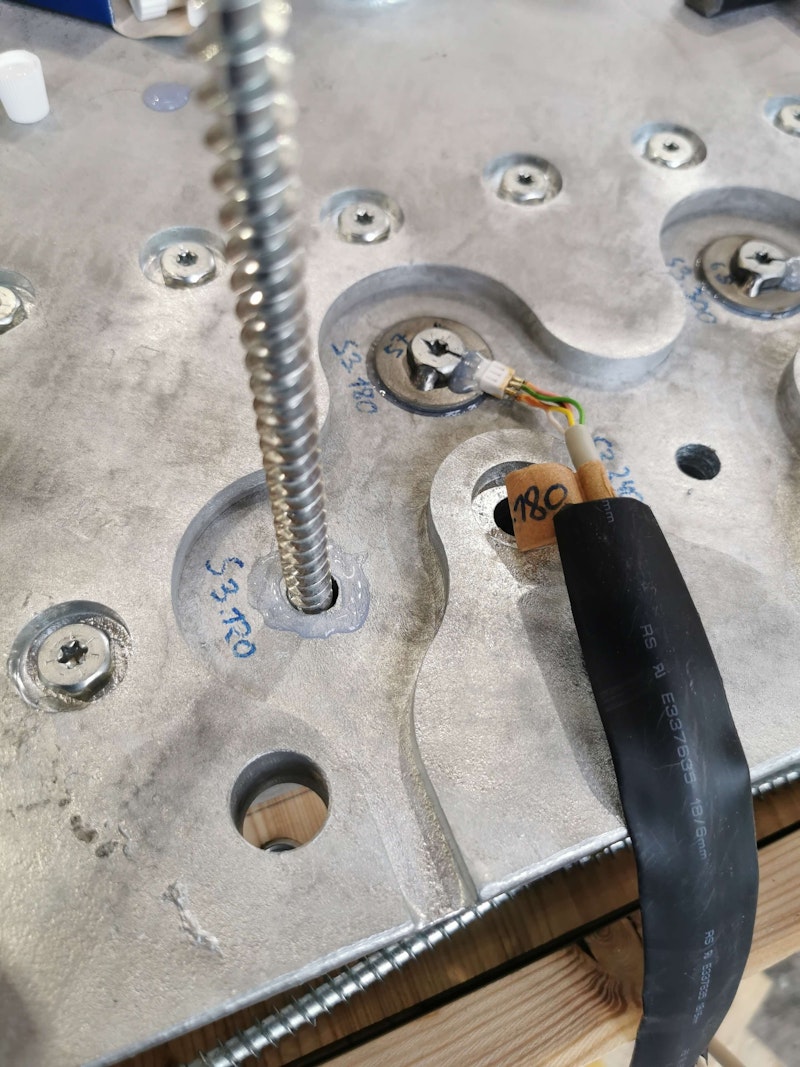

To monitor the forces inside the structure, for accuracy reasons, the engineers preferred to measure in the steel parts because the stiffnesses of timber scatter too much. Therefore, they had to instrument the screws and threaded rods.

First, the team drilled a hole with a 2mm diameter into the high-strength steel. Then, it mounted the half-bridge strain gauges connected by the 5-wire method and glued inside with two-component epoxy glue. Additionally, it spot-welded a washer, holding the electrical connector on top of the screws - carefully because too high-temperature for a longer time causes the screws to lose strength.

The team calibrated the output signal to measure values up to 20 kN for the screws and 80 kN for the threaded rods.

Mr. David Glasner comments on the process: “Although I am a trained civil engineer, I felt more like an electrician during the work.”.

A critical step in the construction manufacturing was the block-gluing: the team added the adhesive, combined the two halves precisely over each other, and everything went into the big block-gluing press. Luckily, all the sensors were still working afterwards.

For the measurement of outside temperature, air humidity, and wind speed, the engineers decided to use a weather station. It provides serial output, which the Dewesoft SerialCOM plugin can decode, so all data is synchronously measured by DewesoftX software - see the DewesoftX manual.

The data acquisition system has 32 channels and contains one SIRIUSi-HD-16xSTGS and two DEWE-43 measurement devices. The devices connect to a computer with an independent power supply and network connection for remote monitoring - all installed and fitted nicely within a control cabinet.

Conclusion

The needed sampling rate is low for long-term monitoring. However, TU Graz uses the “slow storing” feature, storing min, max, average, and RMS values to reduce the data file size even more. Every day, the system automatically creates a new file for easy traceability.

DI David Glasner, assistant of the Institute, is satisfied with the measurement system. Mr Glasner also liked the measurement modules’ DSUB9 connectors for the analog inputs, which are much easier to solder than others.

With the 16-channel SIRIUS, he adds a practical remark: “Users must pay attention to using the slim variant of the DSUB9 housings if they prepare their cables upfront.” However, he is still happy with the compact form factor of the measurement module.

His main concern was the embedded sensors: Would the instrumented screws and rods work as expected? Luckily, they did.

By applying a monitoring system, TU Graz ensures the gantry functionality and can use the data to validate their engineering models. The first year has now passed. The measurements show the ‘green’ gantry is all good. Unexpectedly, the engineers have observed a slight drying of the inner core, which they ascribe to the constructive wood protection.