Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

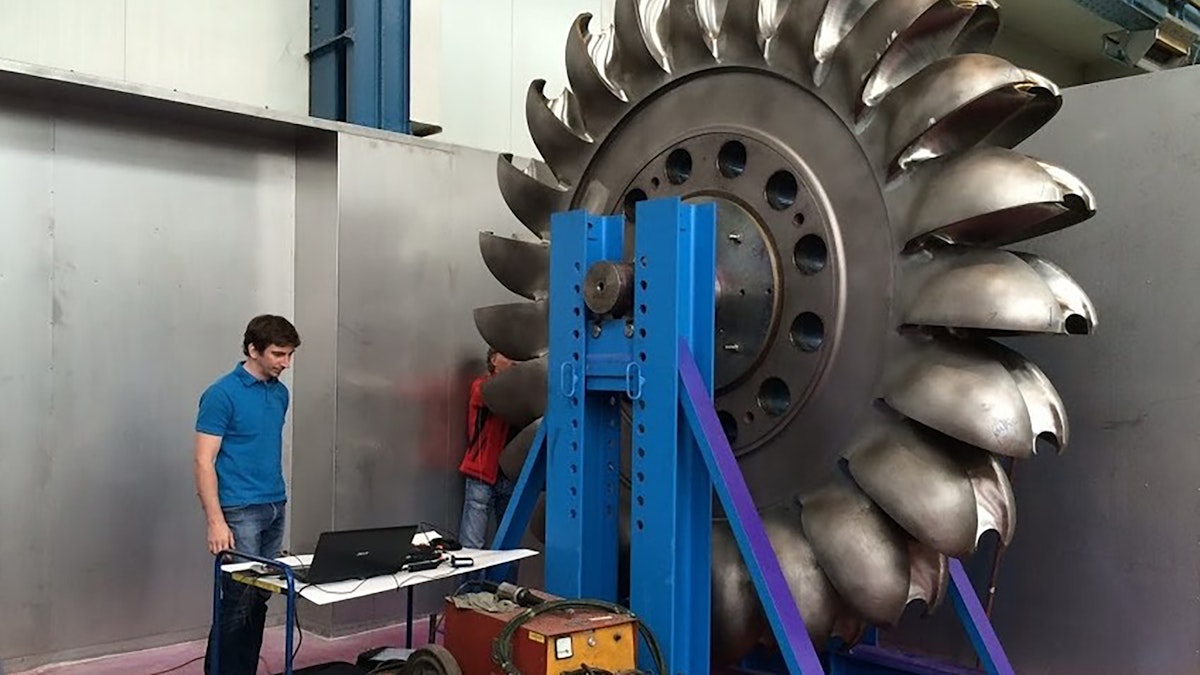

Modal Test on Hydro Turbine Buckets

TIWAG, a major Austrian power plant operator, asked for assistance to validate a redesigned water turbine. Due to wear and repeated refurbishments of the runners, TIWAG has decided to procure new runners. The required strength verifications, including a numerical modal analysis, were already carried out by the manufacturer prior to the measurement. Dewesoft provided an effective field solution for quick validation of turbine modal parameters - and to save the data for evidence in case of future trouble.

TIWAG is the leading energy service provider in the western Austrian Alp region, Tyrol. The company installs and maintains hydroelectric power stations. In addition to hydropower, it also generates environmentally friendly electricity from domestic, renewable energy sources, such as photovoltaics and biomass.

The issue

This big Austrian power plant operator asked for our assistance to validate a redesigned hydro turbine model, which was currently in service at another company specializing in turbine manufacturing.

The redesigned turbine is a Pelton model - a fairly simple design. A large circular disk mounted on a rotating shaft known as a rotor. On the disk are cup-shaped buckets known as buckets evenly spaced around the entire wheel. Nozzles then introduce water jets on the buckets and make the turbine spin.

In this case, the disk has a diameter of approximately 4 meters and weighs 10 tons. It has 23 spoon-shaped buckets, driven by six water nozzles with around 120 bar, runs at a nominal speed of 500 rpm, and generates a power of 250 MW.

The engineers at TIWAG needed a solution to validate the modal characteristics of the new turbine design with a modified bucket shape. This modification is intended to ensure the required safety margin of 10 Hz between the excitation frequencies from machine operation and the critical bucket natural frequencies. Additionally, the new runners were milled from forged discs, whereas the old ones were cast. This should result in reduced variations in the bucket natural frequencies.

Dewesoft offered an effective field solution for validating the modal testing and analysis of the turbine bucket design - and saving the data for evidence in case of future trouble.

Solution setup

Hardware

Dewesoft SIRIUSi custom with 2xACC, 2xACC+, 2xHV, 2xMULTI - 8-channel isolated data acquisition system with USB2 interface

Endevco 2302-100 (scaling: 22,7 mV/N) - modal hammer

PCB 352A56 (scaling: 99,3 mV/g) - acceleration sensor

Software

DewesoftX - test and measurement data acquisition software for data recording, signal processing, and data visualization

DewesoftX-DSA - software package including modal test option, OPT-MODAL-TEST.

Modal testing

In this case, we considered tap testing or experimental modal testing the proper way of testing. This method has the advantage that it only requires a minimum of equipment - only one roving or impact hammer and one sensor are needed.

After a test hammer hit, it turned out that the natural frequencies of the 23 rotor buckets were around 780 Hz. Due to the manufacturing precision of the turbine, they were lying very close to each other, and the phase turned multiple times in a narrow frequency range.

The selection of the sampling rate (5000 Hz) and line resolution (8192 lines, df = 0.305 Hz) was the most critical. We needed to match both settings while also keeping an eye on the resulting measurement time of each hit. It shouldn’t be too long.

The applied frequency resolution required acquiring a rather large amount of data and a relatively long measurement time to calculate one FFT (t = 1 / df = 1 / 0,305 Hz = 3,28 sec). As the massive steel structure has low damping, the ringing tone after each hammer tap lasted for quite a few seconds before fading out. So, leaving enough time between the hammer hits was also important.

The geometry model

In the software’s Modal Geometry Editor, we simplified the bucket to a 2D shape with eight hit points aligned on the upper edge. For proper visualization and shading of the movement, we connected these dots by lines, using a few three-point shapes in between.

The accelerometer was mounted in point no. 8 while we moved the hammer taps through points 1 to 8. We did three hammer taps at each measurement point to obtain a valid average result. And for each bucket, we created a new data file.

Measurement screen

The display in figure 6 is auto-generated by default immediately when the measurement starts. The measurement screen allows online validation of the excitation and response signals in the time- and frequency-domain - to quickly identify double hits and repeat and to see the transfer function and coherence.

The software marks the currently measured point in red. The geometry is rotatable in 3D with the mouse, and multiple visualization options, such as top, side, orthogonal view, and undeformed background shape, are available.

Modal analysis

Measurements completed, we switched to the predefined “Modal test - Analysis” screen to study all the transfer functions - the amplitudes and the phases in a Bode plot. When the phase is turning 180 degrees and the amplitude is at max, this indicates a resonance.

Frequency and damping

The spectrum showed a lot of resonances in a narrow band - in figure 7, we have zoomed in from 750 to 800 Hz. At this time, we were mainly interested in our first mode at around 780 Hz. In this case, the linear y-axis scaling is easier for finding the dominant peak.

The modal circle provided the option to have more accurate results from our experimental modal test. It interpolates between the FFT lines. The structure animation below nicely shows the first mode shape - up/down movement of the bucket and undeformed structure in light-gray color. Notice the low damping factor due to the massive steel structure.

Conclusion

The measurement on all 23 buckets showed an average resonance frequency of 782,5 ± 3,9 Hz. The measurement of each individual bucket enabled the identification of those that may require rework to achieve the required safety margin from the machine excitation frequencies (“detuning” through material removal, e.g., by grinding). The complete measurement process, including making the setup, lasted only around 2 hours, and TIWAG is looking forward to using this simple solution in daily business.

“Our vehicle trunk was always stocked up with equipment and cables when using the previous measurement system,” report the TIWAG measurement technicians. “The Dewesoft system is a much more compact and robust solution. And we now finish testing in a shorter time - and with lots of pleasure!”