Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

How One Metro Upgraded its Rail Infrastructure with Dewesoft DAQ Systems and Knick High Voltage Transducers

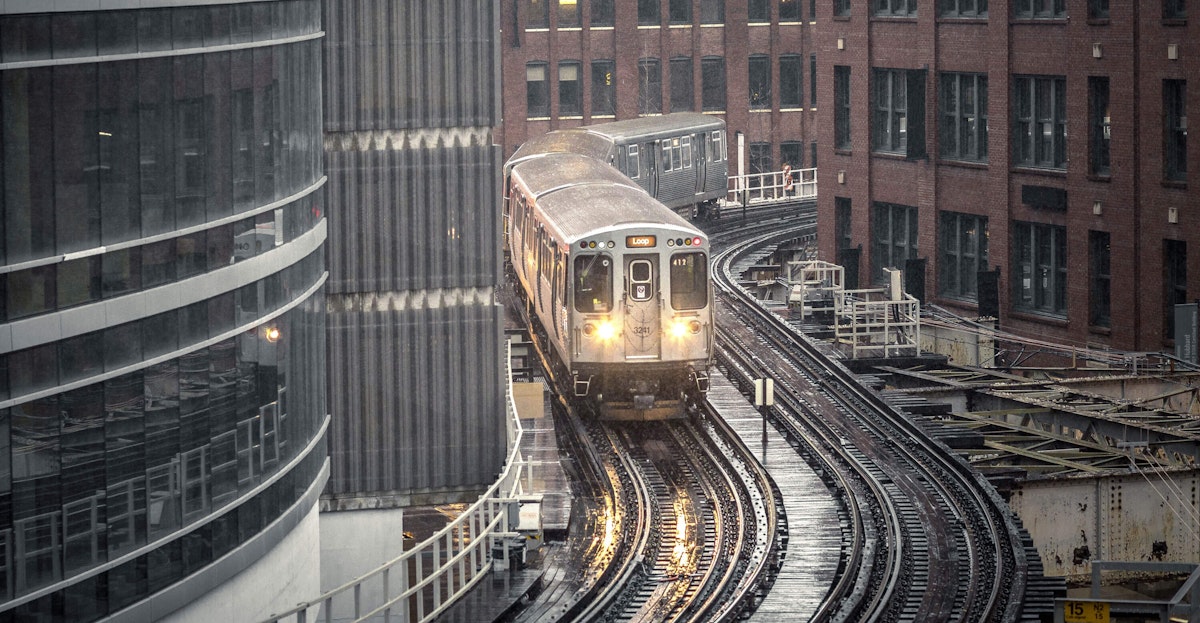

Metros in large and small cities provide daily rail and bus services to billions of commuters worldwide. Rail service requires monitoring and maintaining hundreds of traction power substations, circuit breakers, transformers, rectifiers, and protective relay devices. The rail infrastructure required many voltages, currents, temperatures, and other parameters to be measured. In the case of one metro, the sheer number of channels was impossible to capture with their existing measuring systems. They searched the market for railway data acquisition systems and high-voltage measurement systems to meet the challenge. Here’s what they found and how it helped them.

The challenge

The metro must monitor voltage, current, and temperatures at its traction power substations and tiebreaker stations, which include traction power facilities, high-speed circuit breakers, transformers, rectifiers, and protective relay devices. Electric railcar monitoring, voltage and current monitoring, and substation equipment monitoring are interconnected imperatives that require high-isolation DAQ instruments and high-voltage transducers. Metro engineers realized they needed a distributable system capable of monitoring data in a synchronized way, so they conducted a market search to find a better solution.

Since the metro’s railcars are electric, monitoring high voltages and currents is essential. This data must be obtained safely, so the hardware requires sufficient electrical isolation. Measurements must also be highly accurate and available quickly. Understanding these electrical quantities as they relate to the performance of the substation equipment is essential.

Potentially dangerous events like short circuits can be identified and dealt with expediently through a transducer’s communication to a high-speed circuit breaker. Safety, speed, and accuracy also play an essential role in recording fast transients seen during various rail system operating conditions.

Transformers and rectifiers convert power from AC grid voltage and apply the power to the rail system. Temperature increases can indicate loose, worn, or failing electrical connections, so monitoring them at key measurement points is essential.

Accurate voltage, current, and temperature monitoring allows the metro to address issues before they interrupt service or cause safety issues. Constant monitoring enables the metro to determine the overall health of the rail lines while providing invaluable historical data to assess the root cause of system anomalies and prevent service interruption by keeping maintenance teams informed of conditions on the line.

Metro engineers studied the market and discovered Dewesoft's rugged KRYPTON DAQ instruments.

Solution #1: KRYPTON

KRYPTON DAQ modules combine IP67 liquid and dust protection, an extreme operating temperature range of -40 to 85° C (-40° to +185° F), and 100 g shock protection without sacrificing performance. Their compact form factor would make integrating KRYPTON modules into the metro’s instrumentation cabinets fast and easy.

Regarding DAQ performance, KRYPTON modules use 24-bit ADCs with anti-aliasing filtering on each channel. KRYPTON modules provide high precision and bandwidth. Their isolation and industry-standard connectors were also important considerations. KRYPTON modules interconnect via EtherCAT, an interface similar to Ethernet except adapted for DAQ systems to carry power, signal, and timing on a single cable. The EtherCAT protocol provides time synchronization among all modules on the chain.

With its 20 kHz sample rate, the KRYPTON 8xLA module simultaneously provides FFT and harmonic analysis of all analog inputs. These features and the ability to create custom math formulas and filters and calculate real-time statistics make Dewesoft a great solution.

The digital inputs of KRYPTON 16xDI modules monitor and capture the DC relays' digital (on/off) signals. These digital signals trigger recording at the maximum sample rate before and after a breaker trip event to capture transient spikes in high fidelity without missing peaks. These high-speed recordings are critical to determining the root cause of failures while informing metro engineers of solutions to prevent recurrences.

Solution #2: DewesoftX software

DewesoftX power analysis software

DewesoftX is the standard software included with all Dewesoft DAQ instruments. It provides a complete hardware setup capability, user-configurable displays, continuous or triggered recording functions, and a robust mathematical engine. DewesoftX is an award-winning program with numerous modules that enhance it to perform specialized functions.

The metro is required to perform real-time power analysis, so they opted for the DewesoftX POWER module to access standard power and efficiency calculations, such as active, reactive, and apparent power. DewesoftX shows voltage, current, and power in an easy-to-read, customizable user interface. Specialized visual widgets like the classic vector diagram are included, and all calculated values are shown in real time on the user-customizable display screens.

Dewesoft NET

If you can’t easily access it, all of the data in the world has no value. Remote data access is imperative because the metro’s sub- and tie-breaker stations are distributed across a wide area.

DewesoftX software with the Dewesoft NET module allows remote data viewing and control. This functionality enables the metro to access each DAQ system and view real-time data via their local network. Metro engineers can access any networked station from a computer in their office. They can watch the data without interrupting the recording and remotely control the DAQ systems.

Solution #3: portable SIRIUS instruments

Metro engineers needed portable and easy-to-move DAQ instruments to conduct spot checks in the field. For these applications, they chose the SIRIUS line.

After reviewing their requirements, they decided on two SIRIUS-HS (high-speed) modules plus a high-performance SBOX CPU to run the software and store the data. SIRIUS’ eight high-voltage inputs natively support up to ±1600V without transducers, and the eight low-voltage inputs can be used with clamps or shunts for current measurements. All inputs are sampled simultaneously at selectable rates up to 1 MS/s/channel. The system’s 12-inch multi-touch display makes this solution ideal for taking on-site measurements.

Dewesoft’s entire line of DAQ instruments is interoperable. SIRIUS, KRYPTON, IOLITE, and OBSIDIAN can be interconnected in countless ways, making the metro’s investment cost-effective and practical.

Since the early 2000s, one of the hallmarks of Dewesoft DAQ systems has been integrating video with analog and digital sensor data. Video adds a new layer of context that can be priceless in specific applications. The metro chose a DS-CAM-640C synchronizable camera to record video up to 640 frames per second. The video and sensor data are shown on the same screen during and after recording.

Solution #4: Knick transducers

The metro’s electrical specifications detail a comprehensive list of performance requirements for transducers. This includes calling for continuous isolation at a minimum of 2.2 kV to withstand permanent voltages and a test voltage of 10 kV for protection against fast transients. To accurately capture transient events, measured values must be linear to at least 200% of the transducer’s nominal range. Related to transmission speed, a 90% input range change must be converted to the output (known as T90) in a time not to exceed 110 microseconds.

The metro selected Knick’s P41000 series current transducers and P42000 series voltage transducers. These models met or exceeded the project’s electrical specifications and have many years of proven performance as transducer standards in challenging rail industry applications.

These devices are compact and are DIN-rail mountable. The input/output settings are flexible, and the universal power supply supports 20 to 253 V AC/DC. Galvanic isolation is provided across the input, output, and power supply (3-port) with continuous voltage protection up to 3600 V AC/DC.

The P41000 measures current via shunt voltage, with a nominal input selected by the metro of ±50 mV. Coupled with a high-performance shunt, this allows currents up to 25 kA DC to be accurately and safely measured.

With the P42000 voltage transducer, the metro intended to monitor a nominal bipolar range of 1000 V DC, with the capability to see disturbances in the system to ±2000 V DC. The benefits of Knick high-voltage transducers in rail systems were immediately apparent, given that they provided data at cutoff frequencies beyond 5 kHz.

Conclusion

The metro invested strategically in solutions from Dewesoft and Knick to effect their railway system upgrades. The scaled outputs from the Knick transducers fit perfectly with Dewesoft’s KRYPTON module inputs. These instruments collect and analyze historical and real-time data, empowering Metro engineers to make quicker and better-informed decisions. They can detect and react to unexpected power distribution system failures in real time. The safety of the electric systems and their customers is their paramount concern.

Monitoring and maintaining traction power facilities is a huge challenge. However, combining these solutions with the metro's rail engineering expertise reduced downtime, improved on-time performance, and increased efficiency. These enhancements make for happier commuters.

Learn more about Dewesoft and its Railway Monitoring solutions:

Learn more about Knick International and its Railway interface solutions: