Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Formula Student - The UNI Maribor Grand Prix Engineering Team

February 16, 2026

Worldwide engineering students develop and produce racing cars and compete on the most famous tracks. Dewesoft Data Acquisition systems help Slovenian students understand their race cars, and solve technical issues... and helps Dewesoft find and recruit motivated engineers.

Did you know that Slovenia has a team of young engineers who independently develop powerful racing cars to compete on the most famous racing tracks in the world?

Did you know that Slovenia has a team of young engineers who independently develop powerful racing cars to compete on the most famous racing tracks in the world?

Students of the University of Maribor join UNI Maribor Grand Prix Engineering and use their creations through Formula Student to make their way into the automotive engineering elite. The first UNI Maribor Grand Prix Engineering team of 30 students was formed in 2011 and since then 9 racing cars have been built and young engineers are currently working on the car of the year 2020.

Formula Student

Formula Student is an engineering design competition - the biggest in the world for students of engineering sciences, every year they compete with their knowledge, and experience and with the help of universities and their sponsors in the manufacture of racing cars and in racing different road stages. Students gain valuable practical experience through participation in the conception, design, production, testing, and racing a car, as well as preparing a business plan and cost report.

The concept behind Formula Student is that a fictional manufacturing company has contracted a student design team to develop a small Formula-style race car. The prototype race car is to be evaluated for its potential as a production item.

Each student team designs builds and tests a prototype based on a series of rules, whose purpose is both ensuring on-track safety - the cars are driven by the students themselves - and promoting clever problem-solving.

Globally, there are several hundreds of university teams that compete each year in over 40 competitions held at various racetracks worldwide. The competition organizers are professional engineering associations, with the help of the largest companies in the automotive industry, such as Porsche, Daimler, Audi, Jaguar, and others – the initiative is also meant to train their future engineering personnel.

Connecting to Dewesoft

The team of the University of Maribor Grand Prix Engineering (UNI Maribor GPE) met Dewesoft when we were looking for a data acquisition system for our race car.

We initially asked the local National Instruments office for sponsorship and they were kindly willing to support us with free hardware and software. However, they emphasized that we would need to program an application inside their SW to be able to measure data from the sensors in our car. They could do that for us, but that part wouldn't be free or sponsored. We had neither internal resources nor knowledge to build a measurement application, so this was not really a viable option.

Luckily one of our team members had been sponsored by Dewesoft on his previous project and suggested giving the company a call. We visited the HQ in Trbovlje and Dewesoft offered us free hardware and software – and we did not need to develop the application ourselves!

The Dewesoft X3 DAQ software was already a ready-to-use application itself. We simply had to connect the USB devices (SIRIUS and DEWE-43A) to the SBOX PC, connect the sensors and the data was already coming into the recorders on the screen.

Racecar data acquisition

Racecar data acquisition is quite a complex task for a measurement system since it requires many different DAQ techniques. Typical measured values include:

| Measured value | Sensor | Signal conditioning / Data acquisition type |

|---|---|---|

| Wheel vertical force | Strain gauge/load cell on suspension pull rods/pushrods | Quarter / Half / Full bridge amplifier |

| Damper displacement | Linear potentiometer | 10 V potentiometer analog input |

| Wheel speed | Inductive or hall effect sensors on a toothed wheel | Counter input |

| Steering wheel position | Magnetic encoders | Counter input |

| Brake pressure | Pressure sensor | Voltage input |

| Vehicle body acceleration and rotation speed | Inertial measurement unit | COM port communication |

| Vehicle Location | GPS receiver | GPS NMEA interface |

| On-board video footage | Video camera | Video interface |

| Engine Control Unit (ECU) parameters | CAN communication |

Dewesoft DAQ devices offer all the necessary signal conditioning front ends for analog channels included in the table as well as the counter inputs. We used an 8-channel SIRIUS-STG slice to connect full bridge strain gauges and potentiometers from each of the four wheels. A DEWE-43 provided 8 additional analog and counter channels.

Counter channels were used for wheels speed sensors and the steering wheel encoder while the analog channels of the DEWE-43A came handy for brake pressure and other auxiliary sensors. SIRIUS and DEWE-43A also provide CAN bus interface which we used to connect to the MoTeC ECU to read all sorts of engine parameters: RPM, throttle position, oil, and water temperature.

Dewesoft also provided us with an IMU and GPS device (DS-IMU-2) that had to be connected over a COM port to the PC running Dewesoft X software. The same goes for a high-speed video camera that we connected over Ethernet (GigE).

Dewesoft – simple and effective

The integration of all those signals was seamless in Dewesoft: you set up the analog channels in the »Analog In« menu, counter channels in the »Counters« menu, GPS in its own menu, there is a special plugin for IMU set up and the CAN bus menu has its own easy to use CAN decoding tool.

Even if the hardware consists of several different sensors and devices, the user does not feel any complexity when working with the GUI of Dewesoft X DAQ software. All there is are time-based channels of data that can all be stored or used in mathematical channels. All the signals in Dewesoft are also synchronized, no matter the type (analog, digital, GPS, video).

We did not have much experience with measurement technology as there were predominantly mechanical engineers in the team. Dewesoft made our life easier as it was just plugged and play. Take strain gauges as an example. Wiring diagrams in the Dewesoft channel setup gave clear instructions on how to wire them. If you swapped plus and minus input wires, you just hit the +/- button in the setup and the signal was in the right direction.

We scaled the strain gauges on the pull rods by jacking the car on four weight scales and used Dewesoft's two-point calibration: input the weight values with an empty car, then have a heavy driver sit in the car and input the new weight values from the scales. Finally, the parameters were saved to a TEDS chip in the DSUB9 connector of the strain gauge inputs which auto-configured any channel to which the sensor was connected at any time.

The Dewesoft X Math module was especially useful for our analysis of car behavior. To observe the lateral acceleration in corners the acceleration channels had to be low pass filtered to about 5 Hz. The damper displacement values were used in equations for pitch and roll calculation. Video and GPS data was extremely useful in post-processing to reference the location on the race track. Polygon plugin was also used for the display of the race track and the car.

The purpose of the data acquisition was to understand the behavior of the car and improve its characteristics. We could see the peak accelerations and wheel loads that occur on the race track and compare that to our simulated values to validate our design as well as improve the design of next year's car.

Formula Student - UNI Maribor Grand Prix Engineering (GPE) - Cars

| 2011 | 2012 | 2013 | |

|---|---|---|---|

| Competitions | · FS Germany 2011· FSAE Italy 2011 | · FS UK 2012· FS Austria 2012· FS Germany 2012 | · FS UK 2013· FS Germany 2013· FS Austria 2013 |

| Mass | 242 kg | 211 kg | 178 kg |

| Max power | 60 kW | 62 kW | 35 kW |

| Frame | Aluminum tube chassis | Aluminum tube chassis | Aluminum tube chassis |

| Engine | Honda CBR 600 RR PC40 | Honda CBR 600 RR PC40 | KTM 450 SX-F |

| Gearbox | Sequential with 100ms of gear shift timing | Sequential with 100ms of gear shift timing | Sequential with 75ms of gear shift timing |

| Wheels | Keizer | OZ racing 13″ | OZ racing 13″ |

| Acceleration | 0-100km/h: 3,5 s | 0-100km/h: 3,4 s | 0-100km/h: 3,7 s |

Problem – wheels off the ground

A particular problem occurred in the early testing of the GPE12 car that was addressed by using the acquired data: the car suddenly got both inside wheels off the ground in one of the curves and only a quick reaction by the driver prevented it from rolling over. We could not really understand this phenomenon as the combination of wheel track (1200 mm) and center of gravity height (270 mm) allowed for the maximum lateral acceleration of 2.2 g for the inside wheels to stay on the ground.

The recorded data in Dewesoft showed peak lateral acceleration values of 1.7-1.8 g on the very grippy airport tarmac that we used as a test track. In theory that should not be enough force to take the inside wheels off the ground. So, what happened on that particular occasion? The data also showed that the peak lateral acceleration on that occasion wasn’t any higher than on previous laps.

Since the load did not increase, the increase of the roll angle could only be caused by a lower roll stiffness or roll damping. We examined the anti-roll bars and found out that a substantial amount of free play developed in its bearings. The anti-roll bars basically offered no resistance to roll due to this free play. It caused the chassis to gain rolling momentum at the onset of acceleration which tipped the car over.

The calculation of 2.2 g maximum lateral acceleration was based on a quasi-static assumption and did not take into account the roll inertia of the chassis, especially not with the defective anti-roll bars! Finally, our measurement system helped us pinpoint the problem and even fix it the same day it occurred.

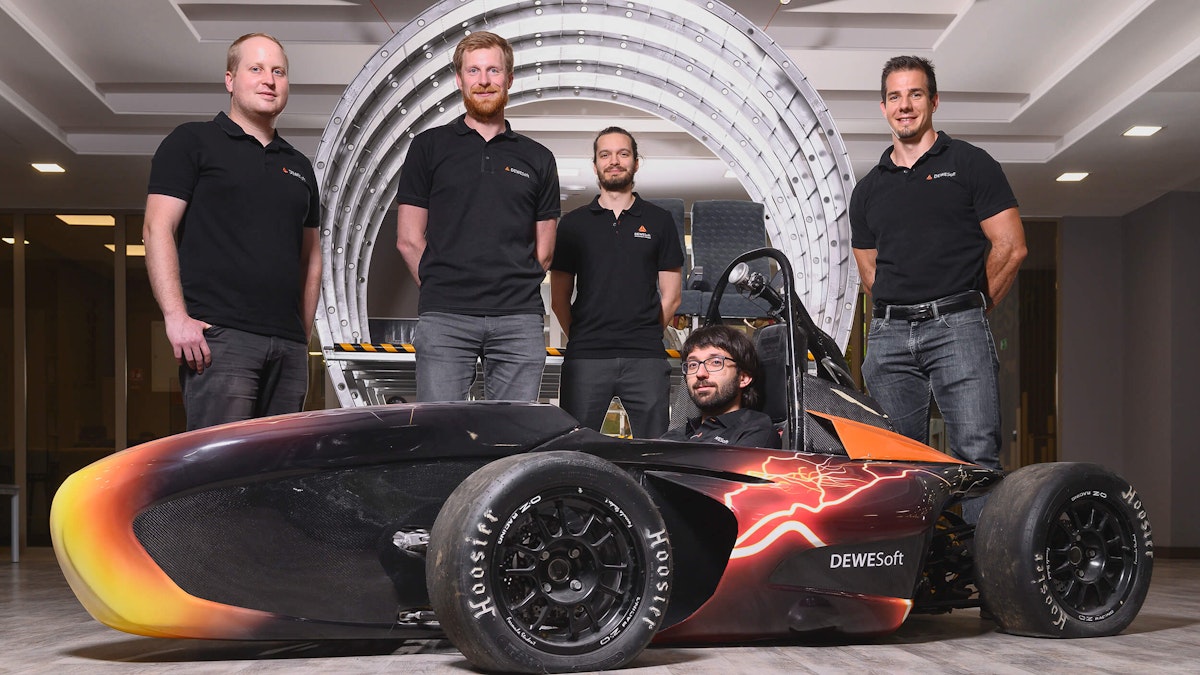

Employed by Dewesoft – the GPE gang

The experience of working with Dewesoft hardware, software, and the Dewesoft team persuaded several UNI MB GPE team members to join Dewesoft forces soon after their studies. There is now a »GPE gang« of five in the company.

Bojan Čontala was the first member to join Dewesoft right after he finished his GPE duties as a team captain in 2013. Being a mechatronics engineer he was responsible for DAQ and electronics and worked with the Dewesoft system in 2012 before taking over the role of team captain. He drove the team's van on his own for 26 hours straight from Maribor to Silverstone, UK. He is doing more of the same today as a regional sales manager for Europe in Dewesoft.

Two years later three more ex-GPE members joined Dewesoft: Luka Jerman, Aleksander Klemenčič, and myself. Luka played many important technical roles in the GPE team right from the start in 2011, working in composites simulation and design (2012) then in vehicle dynamics simulation and suspension design (2013) and finally as technical director (2014). Today Luka is a software developer for automotive applications in Dewesoft.

Alex was a jack of all trades and master of many already back then. He worked on the sequential shifting mechanism, electronics, engine tuning, and welded 0.5 mm aluminum when needed. In 2012 we had a big car launch in central Maribor with the Slovenian minister of education present. The engine did not fire up just half an hour before the event. When everyone lost hope, Alex opened the MoTeC ECU and soldered a wire onto the PCB that solved the problem. He does more of the same today as a key developer focused on low-cost DAQ devices.

I co-founded the GPE team in 2011 and was team captain for the first two seasons. It was an unforgettable ride, designing the car, chasing for sponsors, racing around Europe against competitors from all over the world. It is not all that much different today in my role as a managing director of MonoDAQ.

Soon after Primož Gorenšek joined as well. I think the GPE project might have lasted less than a year if it wasn’t for Primož. He was the only guy in our first year who was able to work with the engine and its electronics – and actually made it work. Well, he did destroy a few of them as well, you can still find smashed valves and pistons in the GPE workshop in Maribor. Primož is now an Automotive and Combustion application engineer at Dewesoft and works closely with Bojan and Luka still today.

Final thoughts

“Formula Student is the best engineering school in the world”, founder and president of the international vehicle dynamics consultant group OptimumG, Claude Rouelle, said in an interview, "Formula Student success is not just about designing good cars, it is about designing good teams".

And sure, both were achieved in Slovenia. The GPE certainly fulfilled its purpose for our part – it added the practical experience to the theory that enables us to contribute to an advanced electronic company supplying the automotive industry worldwide. The UNI Maribor Grand Prix Engineering team is recruiting again in March 2020!