Table of contents

Browse categories

Browse authors

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Energy Flow Analysis of Electric Vehicle With Power Analyzer

April 8, 2023

As the economic performance of new energy vehicles is one of the most concerning performances to customers, car manufacturers are also working hard to increase vehicle mileage. Therefore, the economic performance of electric vehicles is particularly important.

And China's new energy vehicle subsidies are related to the economic performance of electric vehicles. Hence, the OEMs are studying the economic performance of new energy vehicles. The Dewesoft power analyzer provides a flexible solution for all power analysis calculations as well as electrical power and mechanical power measurements.

In the process of vehicle development, in order to analyze the economic performance of new energy vehicles and understand the energy destination and utilization of electric vehicles during operation, researchers in new energy and development manufacturers (such as BJEV, Xpeng, etc.) need to perform energy flow analysis on vehicles under development and benchmark vehicles.

These researches are analyzing the energy transfer efficiency and the proportion of energy consumption among the various subsystems, amending the economic performance analysis simulation model, and guiding the formulation of reasonable performance indicators.

The challenge - power analysis

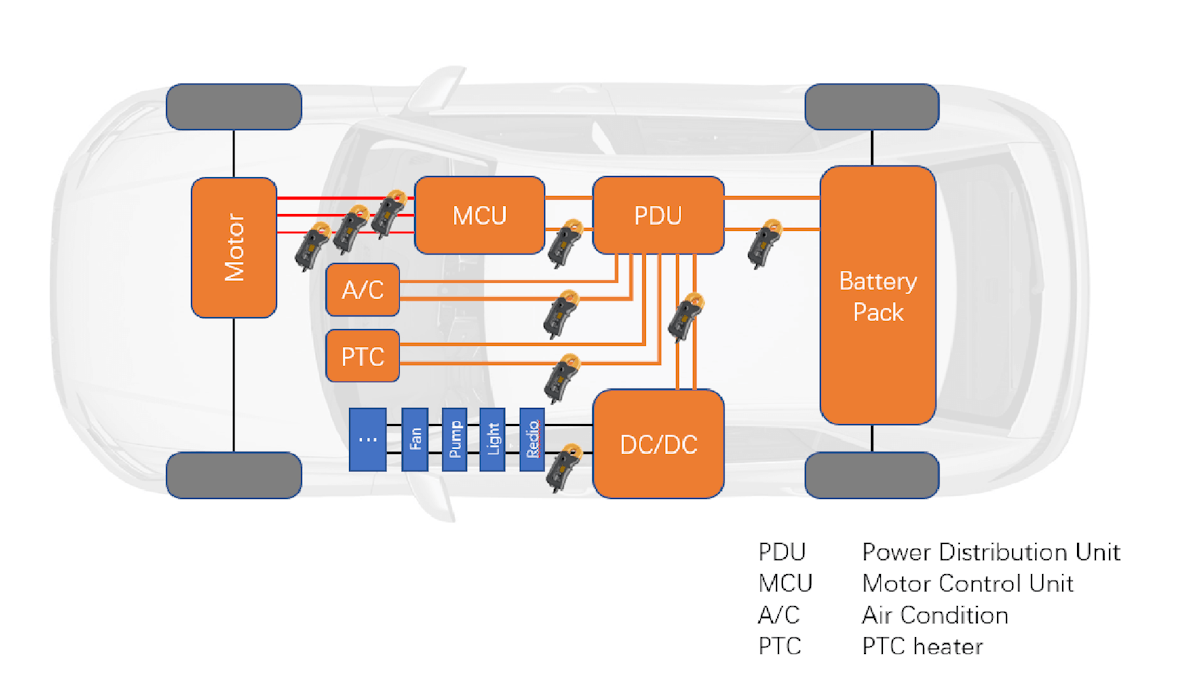

Electric energy from the grid flows into electric vehicles. The entire vehicle system connects power conversion devices such as power batteries, motor controllers, drive motors, and reduction gears in series to achieve the transfer, conversion, consumption, and utilization of electrical and mechanical energy.

According to the energy flow diagram and energy analysis theory, the working efficiency of each part of the pure electric vehicle can be obtained.

For example, by calculating the ratio of the cumulative output power of the power battery to the total input energy of the power grid, the working efficiency of the power battery under a driving condition can be obtained; by calculating the ratio of the power recovered by the power battery to the available kinetic energy of the vehicle, the braking energy recovery efficiency can be obtained.

Multifunctional solution

The powerful Dewesoft power analyzer meets the requirements of the needed measurements. It provides a flexible solution for all power analysis calculations as well as electrical power and mechanical power measurements.

Due to DewesoftX software, the DAQ system combines multiple functionalities in a single device:

Power Analyzer

Combustion Analyze

Oscilloscope

RAW Data Logger

Spectrum Analyzer

CAN logger

etc.

ensuring smooth data synchronization, visualization, storage, or data comparison.

Voltage measurement

The Dewesoft SIRIUS HS (High Speed) HV (high voltage) channels can collect voltages from ±1600V to ± 20V, meeting various test needs. The battery voltage of pure electric passenger cars is generally between 300V and 420V. Low-voltage circuit voltage is generally 12V, 24V, or 48V.

High current measurement

The discharge rate of the battery is generally below 1C. When the vehicle is accelerating rapidly, the peak discharge rate may reach 2C or more, which is converted into a current of approximately -300A ~ + 500A.

Customers need to install the current sensor quickly, so they choose DS-CLAMP-500DCS high-precision open-loop current clamp with a range of ± 500A.

Learn more

Low voltage and small current measurement

There are some low-voltage electrical loads on electric vehicles, such as lights, radios, cooling fans, cooling water pumps, etc. Their working current is about 2A ~ 40A, and the working voltage is 12V or 24V.

It is collected by DEWENET's DN-SHUNT-XXA current sensor, which is installed in the fuse box and replaces the original fuse, which is convenient to install.

Mechanical energy measurement

The customer needs to monitor the mechanical energy output from the half shaft to calculate the energy conversion efficiency of the electric motor and reducer.

The power of a rotating object is equal to the product of torque and speed divided by 9550. The torque measurement uses a wireless shaft torque sensor with high accuracy and low signal noise. Wheel speed is measured using a digital incremental tachometer.

Pure electric vehicles come from power batteries and belong to a single energy source system. The transmission path is relatively simple. When the vehicle is running, the power battery transmits the stored electrical energy to the Motor Control Unit (MCU) through a Power Distribution Unit (PDU).

The MCU converts high-voltage DC to high-voltage AC so that driving the motor to work. The motor converts electrical energy into mechanical energy and transmits it to the wheels through the reducer in order to drive the vehicle.

For a pure electric vehicle with a braking energy recovery function, a part of the kinetic energy is transmitted to the drive motor through the wheels and the reduction gear transmission under braking. Meanwhile, the motor plays the role of a generator, which converts mechanical energy into electrical energy, then the motor outputs the electrical energy to the power battery so as to store.

In addition, in order to maintain the normal operation of the low-voltage system, the battery management system will charge a portion of the power battery through the DC / DC converter if the 12V low-voltage battery is short of power.

The Dewesoft power analyzer meets this measurement. By installing sensors on each path of energy transfer, voltage and current can be obtained.

The Dewesoft X power module can calculate instantaneous power in real-time and integrate the transferred energy. At the same time, positive energy and negative energy can be calculated.

Using Math to write simple formulas, the power of rotating mechanical energy can be calculated. And using the integral function can get energy. In this way, the data can be output in real-time and the results can be obtained immediately after the test.

Conclusion

This solution has been accepted by more and more new energy vehicle R&D institutions in China. About 30 car companies in China currently use Dewesoft power analyzers to analyze electric vehicle energy flow, and the number of customers is still increasing.

Due to its compact size, the DAQ equipment can be used for onboard tests and bench tests, and the software is very easy to use.

Dewesoft DAQ hardware is flexible, and the ease of use of the software is the most satisfactory for customers. Since the power analyzer can also be used with other plug-ins such as Brake Test, the customer can analyze the motor response process and energy recovery during the power performance test or brake test. In addition, the solution can be extended to test hybrid vehicles and hydrogen fuel cells.