SIRIUS® Modular

Modular Data Acquisition (DAQ) System

Order analysis is a technique for analyzing noise and vibration signals in rotating or reciprocating machinery. It can provide complete diagnostics for generators, combustion engines, compressors, turbines, pumps, and rotating shafts.

Dewesoft order tracking analysis solution is extremely powerful. It is dead simple to set up and provides real-time calculations, visuals, and results on multiple input channels in parallel. Flexible and powerful data acquisition hardware will adapt perfectly to your testing setup. Our solution includes an industry-leading 7-year warranty, lifetime free software updates, and free technical support.

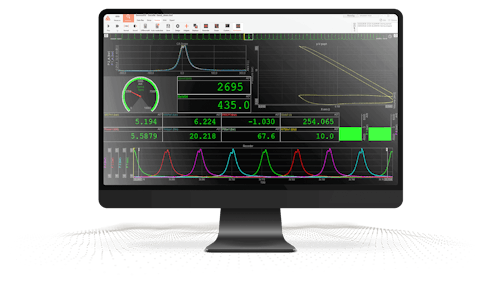

Dewesoft order analysis solution provides data acquisition, storage, visualization, and calculation on unlimited input channels online. Multiple rotating machinery can be observed and analyzed in parallel.

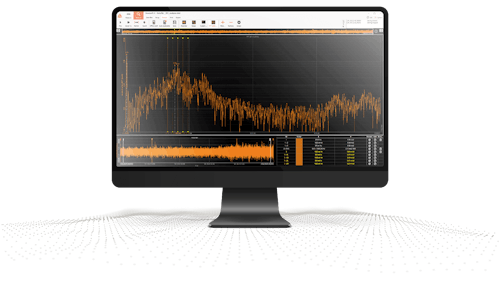

High sampling rate and advanced alias-free resampling mechanism allow measurement in all three domains - time domain, frequency domain, and order domain. All data is available in parallel in real-time, visualized on the same screen, and stored in the same data file, fully synchronized.

The Dewesoft system is very flexible and offers many additional functionalities for in-depth insights into rotating machinery dynamics. FFT analysis, orbit analysis, torsional vibration, electrical power analysis, and others are available. In addition, other types of sensors can be connected to simultaneously capture vibration, strain, temperature, video, sound, etc. with precise synchronization.

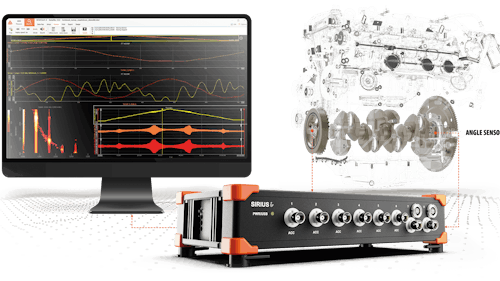

We support any type of angle sensor for determining the angle and rotational speed: tacho sensors, encoders, gear tooth sensors, gear tooth sensors with missing or double teeth, zebra tape, and analog angle sensors. Our system can perfectly determine the angle and rotational speed with 10 nanoseconds resolution using Dewesoft Supercounter technology.

In situations where mounting a tacho sensor to measure the speed signal isn't feasible, the Order Tracking Module provides a smart tracking algorithm. This algorithm effectively isolates the first order (speed signal) out of the vibration sensor. You can further enhance this by adjusting the settings, both during initial processing and in post-processing. For instance, you can specify the anticipated incline of the ramp during acceleration or utilize a pre-filtered mathematical signal as the input source.

Analyze order spectra over time, speed (rpm), or in relation to another user-selected reference channel in 3D spectrograms. Select a user-defined channel as a reference tag axis and correlate other measured physical quantities with the order spectra. E.g. inspecting order levels vs. temperature, wind speed, flow, or thrust. Single click creation of FFT and order waterfalls versus speed or any other reference quantity.

To prevent jumps between spectral bins you can define Delta-RPM and hysteresis and split the RPM range into corresponding bins for calculation. Decide whether data is collected continuously or at the center of bins. Bin update defines how order spectra in bins are calculated and can be set to "first", "always", "averaging", or "maximum".

Supporting full or fractional order extraction with amplitude and phase, that can be coupled with multiple representation options versus rotational speed and in the time domain. A complete representation of unlimited orders on a 2D or 3D graph.

Single or double, integration or derivation, and A or C frequency weighting are all supported directly in our order tracking analysis module. You can have all you need in a single setup screen.

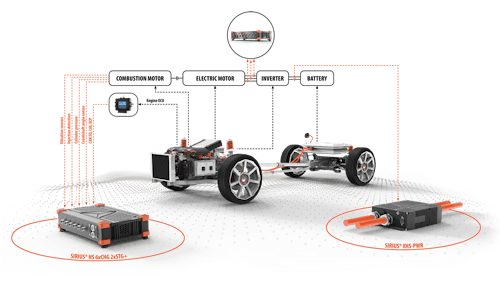

Order components caused by inverters using Pulse Width Modulation techniques can be analyzed using the direct support for demodulation.

Frequency, 2D, and 3D plots provide a great visualization tool to determine the health of the machine. Additional Nyquist, Bode, and Campbell plots are available for the perfect presentation of the data, orbit analysis with raw or order view is a great tool for turbomachinery analysis.

Orbits (raw, averaged, H1, H2, etc.), FFTs, cascade plots, Bode plots, and polar plots can be uploaded to the Historian time-series database for long-term or permanent condition monitoring applications.

Dewesoft systems feature plug-and-play sensor detection for accelerometer and angle sensors that support TEDS IEEE 1451.4 standard.

Use a single-speed source and perform extraction on different gear stages of your machine by using the tacho divider & multiplier functionality.

Enjoy our industry-leading 7-year warranty. Our data acquisition systems are made in Europe, utilizing only the highest build quality standards. We offer free and customer-focused technical support. Your investment into the Dewesoft solutions is protected for years ahead.

Every Dewesoft data acquisition system is bundled with award-winning DewesoftX data acquisition software. The software is easy to use but very rich and deep in functionality. All software updates are free forever with no hidden licensing or yearly maintenance fees.

And we're confident you'll love it too! But don't just take our word for it. Get hands-on with a demo unit, completely free of charge. No strings attached, just real data. Reach out to your local Dewesoft team and get your demo unit now!

It includes everything you need for advanced data acquisition and common signal processing — no maintenance fees, no contracts. You buy it, you own it. All future updates? Free forever. And the best part? Analysis seats are unlimited and free. Once the data is recorded, anyone can download our software to review and analyze your data — no license needed.

Dewesoft is 100% owned by employees who believe in what we do — and love doing it. We’re in this with heart, passion, and long-term commitment. What does that mean for you? Our core value — caring for our customers — isn’t going anywhere. We’re here for the next 100 years, protected from outside acquisitions. Your investment in our technology is safe, supported, and future-proof.

At Dewesoft, quality isn't just a promise — it's a core value. Our products are 100% designed, developed, and manufactured in-house, right in the heart of the European Union. From precision machining and PCB manufacturing to final assembly and software development — we do it all ourselves, to the highest ISO standards. We're proud to support local production and take social responsibility seriously.

At Dewesoft, quality is more than just a word — it's a commitment. That's why our products come with an industry-leading 7-year warranty. It's just one more way we protect your investment and give you peace of mind for the long run.

Order analysis is a technique for analyzing noise and vibration signals in rotating or reciprocating machinery such as engines, compressors, turbines, and pumps. The first order refers to the speed at which the machine rotates. Each order thereafter is a corresponding multiple of the rotational speed.

These machines have a variety of parts, each of which contributes unique noise and vibration patterns to those of the whole machine. With order analysis, you can identify and isolate these patterns to analyze the performance and quality of each machine part individually.

Since orders are independent of the speed of the machine, order analysis is the preferred analysis tool to use when measuring the non-stationary vibration of machinery that runs with varying rotational frequency.

The Dewesoft order analysis solution is an indispensable tool for analyzing the operating condition of the rotating machinery such as resonances, stable operation points, and determining the cause of vibrations. Analyze vibration on engines or other rotating machinery, both in development & optimization as well as in diagnostic & troubleshooting instances. Powerful software and flexible data acquisition instruments, make up a smart portable solution for both developers and service engineers.

Learn more about order analysis in this The Ultimate Guide to the Order Analysis article.

Rotating machines are a major and critical component of many mechanical systems throughout the industry. Almost every industrial process uses at least one rotating machine, which is crucial in the production line. Just ask yourself which machine would cause the biggest cost in the event of a failure?

Engines, power trains, turbines, pumps, compressors, electric motors, ventilation units, etc. can be designed and developed, as well as evaluated and maintained by performing order tracking and analysis:

Investigation and troubleshooting of instabilities in rotating machinery

Determination of critical engine speeds

Gearbox failures

Bearing element failures

Mechanical looseness

Imbalance

Bent shaft

Misalignment

Electrical faults in motors

Cavitation in pumps

Separation of rotational and structural noise and vibration phenomena

Other vibration related problems in e.g. gear, belts, fans, pumps, compressors, and turbines

SIRIUS Mini data acquisition system

DualCoreADC technology, dual 24-bit sigma-delta ADC, 200 kS/s, up to 160 dB dynamic range

Up to four IEPE accelerometers

Up to one tacho sensor

SIRIUS modular DAQ system

DualCoreADC technology, dual 24-bit sigma-delta ADC, 200 kS/s, up to 160 dB dynamic range, +-1000 V galvanic isolation

Up to eight IEPE accelerometers

Up to eight tacho sensors

SIRIUS R1DB or SIRIUS R2DB DAQ systems

DualCoreADC technology, dual 24-bit sigma-delta ADC, 200 kS/s, up to 160 dB dynamic range

Up to 16/32 IEPE accelerometers

Up to 16/32 IEPE accelerometers

Up to 16 tacho sensors

Built-in computer, SSD storage, display, Li-Ion battery

Dewesoft data acquisition systems utilize a patented and registered trademark technology called SuperCounter®.

Counter inputs can measure the RPM and angle of rotating machines. In comparison to standard counters, which only output integer numbers one sample later (e.g. 1, 1, 2, 2, 3, 4), the Dewesoft SuperCounter inputs are able to extract accurate values like 1.37, 1.87, 2.37, etc. fully synchronized for time and amplitude.

This is done by measuring the exact time of the rising edge of the signal with an additional counter. Our SuperCounter inputs work on a 102.4 MHz time base, independent of the current analog sampling rate.

Counter inputs are fully synchronized with analog, CAN bus, and other data sources to enable easy applications like balancing, order tracking, and torsional vibrations.

Due to the rotational order tracking process order analysis is the preferred tool for test, diagnostics, and troubleshooting of machines and other rotational components that run with variating speeds.

Order tracking provides stable spectral results across speed variations with no spectral smearing. Clear vibrational patterns of the individual rotational machine components will be kept throughout the measurements enabling the ability to compare the measured order pattern to reference graphs and to configure individual tolerance and alarm levels for all relevant rotational components.

The order tracking module allows you to select several options before starting the test:

Order waterfall vs. time - monitors order spectra over time and not only the current spectrum.

Order waterfall vs. reference - monitors order spectra over RPM or any other measured channel you want to use as bin axis.

Order domain harmonics - complex channels displayed on a 2D graph, for each user-defined harmonic.

You can always change these settings after you have recorded your measurement. DewesoftX always stores the raw data which allows order analysis results to be recalculated in the post-processing.

Select the RPM limits (upper and lower RPM limit), and whether you want to calculate the waterfall spectrum and order extraction while run-up, while coastdown, or both (to cover the whole frequency spectrum).

Next to order spectral results Dewesoft Order analysis also gives the option to output in parallel FFT spectra over time and over RPM or over another selected bin channel:

FFT waterfall vs. reference- monitors calculated FFT over the selected bin channel.

Time-domain harmonics - complex output channel showing the amplitude of harmonics over time.

Overall RMS vs reference - monitors the overall (full frequency range) RMS value over the selected bin channel.

Peak calculations can be performed in both the frequency and order domains. By selecting the Bin update parameter to Maximum, the maximum values of individual spectral lines are kept throughout the test. Such results can indicate worst-case scenarios by showing the highest peak values across time, RPM, or other bin channels.

Visualization of 3-dimensional values on a single plane is commonly used in order analysis applications. 3D graphs and Campbell plots represents a system's response spectrum as a function of its oscillation regime

With Campbell plots the range of values is segmented in a defined number of levels and each level is represented by a circle, whose radius and color depending on the level's index. Bigger values are represented with larger circles and colors higher on the color map. For a better analysis of data, a cutoff of lower levels can be applied.

How spectra should be collected across the measured range of time, RPM, or another bin axis can be freely configured in Dewesoft.

To prevent jumps between spectral bins you can define Delta and Hysteresis to split the range (e.g. RPM speed range) into corresponding bins for calculation.

Decide whether data is collected continuously over each bin or only at the center of bins.

You can choose between different methods for how to calculate the spectral result:

keep the first calculated bin spectrum in each bin

always update the bins with new calculated spectra

average all spectra belonging to the same bin

hold the maximum spectral values in each bin.

The Dewesoft orbit analyzer is a solution for analyzing and visualizing the movement of a rotating disc.

The orbit plot shows the rotational direction of the shaft. The arrow that shows the direction of rotation is displayed in the top right corner of the graph.

The direction of the arrow is CCW (counterclockwise), therefore we need to choose the channels on-orbit graph in the right sequence.

Learn more about the Dewesoft orbit analyzer.

Dewesoft solutions - a great investment in your future. They are constantly being improved, and new features are being added all the time. All software updates are free of charge forever.

Our industry-leading 7-year warranty on Dewesoft data acquisition systems means your investment is worry-free. We are committed to ensuring that your trust in our measurement equipment will not disappoint - even if the unexpected happens.

Together with world-class data acquisition technology, Dewesoft provides the best solutions your money can buy.

We've gathered all the answers you're looking for, neatly organized just for you.

Order analysis is a technique for analyzing noise and vibration signals in rotating or reciprocating machinery (engines, compressors, turbines, and pumps). These machines have a variety of parts, each of which contributes unique noise and vibration patterns to those of the whole machine.

Order tracking is used with the development or condition monitoring of rotating machinery such as engines, power trains, turbines, pumps, compressors, electric motors, ventilation units, etc. Order tracking applications:

To perform an order analysis you need one vibration sensor (usually an accelerometer, a microphone, or a pressure sensor) mounted on the chassis of the machine and an angle sensor to read the RPM of the rotating shaft.

Both senors will need to be time-synchronized and connected to the data acquisition (DAQ) system for reading. Once data is read you will need data analysis software to perform order tracking analysis.

Dewesoft allows performing order tracking analysis only with an accelerometer sensor. To get the rotational frequency of the motor, the exact frequency math is used, with the option to track the first harmonic.

This math calculates the frequency of the highest peak in FFT and this can be used further in the order tracking analysis instead of the reading from an external RPM sensor. For more details see this guide.

We refer to Engine orders or harmonics of vibration when we describe multiples of the fundamental frequency. So again using the engine as an example, a 4 cylinder 4 stroke engine generates 2 combustion events per engine revolution.

How is Order tracking done?

Order tracking is done by measuring a signal, typically vibration, and calculating FFTs for each predefined area (class) of rotational speed.

On the FFT waterfall vs. Time you display an FFT, that was calculated from an acquired signal, for each time that it was calculated. This gives you an overview of all calculated FFT’s over the time of measurement.

Opposed from the FFT waterfall vs. Time that is updated on each FFT calculation, the FFT waterfall vs. RPM is updated on predefined RPM change.

Order FFT waterfall vs. RPM displays harmonics and their amplitudes over the speed of the rotating shaft.

Can't find the answer you're looking for? Our team is happy to answer your questions.

See and browse related and compatible data acquisition products.

Modular Data Acquisition (DAQ) System

Portable 4-Channel Sound and Vibration Analyzer

Rugged EtherCAT Data Acquisition (DAQ) System

8-Channel Universal Data Acquisition System

8-Channel USB Data Acquisition (DAQ) System

EtherCAT Data Acquisition and Real-Time Control System

Modular Industrial Data Acquisition (DAQ) Systems

Award-Winning Data Acquisition and Digital Signal Processing Software

See and browse related and compatible testing solutions.

Rotor movements examination and assessment

Vibration and frequency analysis with a Fast Fourier transform

Measure angular vibration of the rotating shafts

Vibration monitoring for gearboxes, fans, motors, pumps, etc.

Internal Combustion Engine Testing Solutions

Complete testing solutions for electric and hybrid vehicles