SIRIUS® Modular

Modular Data Acquisition (DAQ) System

Precise rotor movement measurements and advanced analysis tailored for turbomachinery applications. Dewesoft Orbit Analysis is a complete solution that will help you improve the operating efficiency, lower wear, and prevent any potential critical failures of your machine.

Dewesoft orbit analysis system is a great investment and comes with lifetime FREE software updates bringing all future updates free of charge.

Complete set of math functionalities and displays for turbomachinery monitoring. Raw orbit, averaged orbit, harmonic orbit, Bode plot, Waterfalls, runout compensation, reference orbit, and many more.

Our software is designed from the ground up to be easy to use. A few simple steps will take you from connecting the sensors to stored data in minutes.

Dewesoft orbit analyzer will measure, calculate, and display all orbit results in real-time. But it will also store all raw orbit data which means offline calculations using raw signals from proximity probes are possible at any time.

Measurement results from our solution have been compared and matched by us and our customers multiple times against industry-leading solutions such as Bently Nevada 3500, Bently Bently Nevada ADRE, and OROS ORBIGate systems.

Our solution can be applied to any R&D measurement or machine health monitoring need, regardless of the number of bearings analyzed and/or proximity probes used.

Simply add any desired number of bearings to the analysis.

SIRIUS DualCoreADC converter technology provides an astonishing 160dB dynamic range out-of-the-box for the most precise measurements.

Dewesoft data acquisition systems offer sampling rates of up to 200 kS/s, which is suitable for the analysis of high-speed rotors.

The signal amplifiers on our data acquisition systems cover the needed ranges and supply excitation to the majority of proximity probes on the market. Have existing probes been installed? No problem you can use those easily.

Our data acquisition systems feature plug-and-play sensor detection with proximity probes that support TEDS IEEE 1451.4 standard. With TEDS functionality connecting and setting up sensors is a breeze.

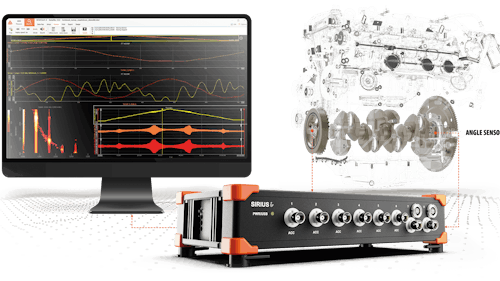

Orbit analysis can easily be combined with other modules provided by Dewesoft. You can perform order tracking, FFT analysis, torsional vibration, and even power analysis or combustion analysis. All in parallel and completely synchronized.

The Dewesoft system is very flexible and offers many additional functionalities for in-depth insights into rotating machinery dynamics. FFT analysis, orbit analysis, torsional vibration, electrical power analysis, and others are available. In addition, other types of sensors can be connected to simultaneously capture vibration, strain, temperature, video, sound, etc. with precise synchronization.

Orbits (raw, averaged, H1, H2, etc.), FFTs, cascade plots, Bode plots, and polar plots can be uploaded to the time-series Historian database for long-term condition monitoring.

Enjoy our industry-leading 7-year warranty. Our data acquisition systems are made in Europe, utilizing only the highest build quality standards. We offer free and customer-focused technical support. Your investment into the Dewesoft solutions is protected for years ahead.

Every Dewesoft data acquisition system is bundled with award-winning DewesoftX data acquisition software. The software is easy to use but very rich and deep in functionality. All software updates are free forever with no hidden licensing or yearly maintenance fees.

And we're confident you'll love it too! But don't just take our word for it. Get hands-on with a demo unit, completely free of charge. No strings attached, just real data. Reach out to your local Dewesoft team and get your demo unit now!

It includes everything you need for advanced data acquisition and common signal processing — no maintenance fees, no contracts. You buy it, you own it. All future updates? Free forever. And the best part? Analysis seats are unlimited and free. Once the data is recorded, anyone can download our software to review and analyze your data — no license needed.

Dewesoft is 100% owned by employees who believe in what we do — and love doing it. We’re in this with heart, passion, and long-term commitment. What does that mean for you? Our core value — caring for our customers — isn’t going anywhere. We’re here for the next 100 years, protected from outside acquisitions. Your investment in our technology is safe, supported, and future-proof.

At Dewesoft, quality isn't just a promise — it's a core value. Our products are 100% designed, developed, and manufactured in-house, right in the heart of the European Union. From precision machining and PCB manufacturing to final assembly and software development — we do it all ourselves, to the highest ISO standards. We're proud to support local production and take social responsibility seriously.

At Dewesoft, quality is more than just a word — it's a commitment. That's why our products come with an industry-leading 7-year warranty. It's just one more way we protect your investment and give you peace of mind for the long run.

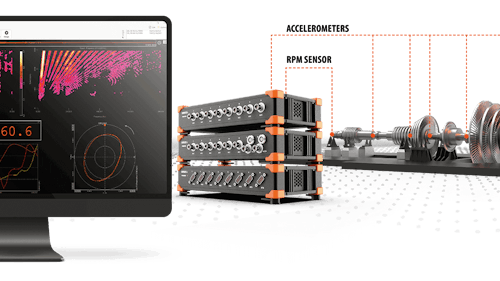

Measuring vibration data on a rotating machine is a strong diagnostic tool enabling the detection and prevention of many types of potential faults and machinery downtime.

Orbit analysis is an ideal analysis tool for rotor movement examination and assessment of any movement restrictions causing vibration. It prevents potential, unwanted damages to rotating machinery that would result in premature wear of components and could cause critical failures. It also helps to determine lubrication state, and bearing states and can optimize machine operation.

Dewesoft orbit analysis works independently of a machine type. It can be a power plant or a high revving compressor. Steady, continuous operation with as few malfunctions and vibrations as possible is essential for maximizing productivity and ensuring the reliable operation of a machine. To achieve this, measurement and analysis of rotational vibration data are crucial.

The Dewesoft Orbit Analyzer is bundled with award-winning DewesoftX data acquisition software and a very flexible DAQ hardware configuration. A simple user interface allows quick configuration, measurement, recording, interpretation of the measured results, and building of a printable report. DewesoftX software offers lifetime free software updates and free technical support which ensures a future-proof solution - and cost-free.

DewesoftX also offers other features useful for rotating machinery analysis such as:

Order tracking analysis

FFT analysis

Torsional and rotational vibration

Octave band analysis

All the measurements can be performed and analysis performed with the same DAQ device and software. This makes Dewesoft the only provider of such a comprehensive solution bundle on the market.

With fully-fledged and complete turbomachinery analysis, easy setup, intuitive presentation of measured data, and industry-leading measurement technology orbit analysis measurement is reinvented the Dewesoft way.

The Dewesoft Orbit Analyser solution can be used for research and development or for operational machine condition monitoring purposes.

Our orbit analysis measurement results have been proven several times by our customers. The measurement and analysis results have been compared to the industry-leading solutions such as Bently Nevada 3500 and Bently Nevada Adre systems, as well as the OROS Orbitgate system.

The comparison results have proven that our measurements are at least as accurate as the industry benchmark systems.

Turbomachinery provides kinetic energy to operations enabling movement - a function that is widely used in industrial processes to move solids, liquids, or gases through drivers, driven components, and transmissions such as:

Compressors

Drills

Generators

Turbines

Engines

Pumps

Blowers

Gearboxes

Above rotating machinery is applied in a variety of industries, e.g. automotive, chemical, oil and gas, metals, HVAC or mining, and in the majority of different power plants:

Hydroelectric

Nuclear

Thermal

Gas

Coal

Biomass

Dewesoft Orbit Analysis system is very flexible and can be configured for single or multiple bearings measurements at the same time. Input channel count can be expanded at any time. DAQ system can also be configured to allow different sensor connections at the same time - thermocouples, RTDs, IEPE/ICP® accelerometers, strain gauges, and more.

The typical Orbit analysis measurement system will consist typically of the following elements:

SIRIUSi isolated data acquisition system with 8xLV signal amplifiers or 6xLV-2xLV+ (additional two counter) amplifiers.

2-8x Eddy-current probes

DewesoftX Orbit Analysis option

Optional:

FFT Analyzer option

Orbit tracking analysis option

OPC UA Client/Server option

Historian time-series database

MODBUS protocol option

Out of the box, Dewesoft Orbit Analysis solution packs the entire set of industry-proven analysis metrics, supporting calculation and graphical representation of:

Raw orbit

Averaged orbit

Filtered orbit

Polar plot

Bode plot

Shaft centerline

Full-motion graph

Clearance circle

Runout compensation

Reference orbit

Complete set of waterfalls.

For more detailed vibration analysis, other Dewesoft modules can be added to the measurement configuration. We can add support for long-term machine-condition monitoring or in-depth turbomachinery analysis together with FFT or order tracking analysis.

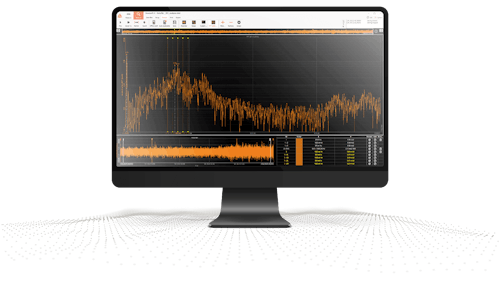

Orbit Analysis module comes will a full preset of display widgets for real-time data visualization. The image shows a predefined orbit analysis screen. The following specific display widgets are available for orbit analysis:

Raw/Direct orbit (with clearance circle)

Averaged orbit (with clearance circle)

Nx/Filtered orbit

Reference orbit

Shaft centerline

Full motion graph

Polar plot

Bode plot

FFT Waterfall

Runout compensation

A set of designated widgets are needed for precise analysis and representation of results. Widgets can be customized in real-time to show standard parameter combinations used in orbit analysis. Standard visual displays such as recorders, digital/analog meters, etc. are also included with the software by default.

Additional inputs like temperature, CAN bus, deformations, vibration, etc. can easily be added and shown on the same screens.

Raw orbit is seen in the orange color on the graph with a clearance circle in turquoise color.

X and Y mark the position of proximity probes, whereas T marks the tacho’s position.

The rotation direction is also shown on the graph with an arrow.

Shows shaft centerline movement in white vs. RPM inside the clearance circle.

The full-motion graph displays the Shaft centerline, Clearance circle, and Raw orbit on the same display widget.

The average orbit is seen in turquoise on the graph with a clearance circle in blue.

X and Y mark the position of proximity probes, whereas T marks the tacho’s position.

The rotation direction is also shown on the graph with an arrow.

The above display widget shows examples of filtered orbits in white, turquoise, and orange. The particular orbits shown are:

X (White)

2X (Orange) and

3X (Turquoise).

A single display in the polar plane displaying phase and amplitude(displacement) at certain RPMs.

Display widget for the complex channel with different available data to display phase and amplitude.

Both orders vs. RPM and FFT vs. time waterfalls are supported. The image shows an example display of order waterfall vs. RPM with an added digital display for speed.

Dewesoft orbit analysis module offers a simple machine and bearing configuration. Machine configuration setup can be further broken down into subsections.

Quick settings: Pair/Mono, CW/CWW, input ch., Angle, Position

Measure: measure the DC gap button

Setup: opens additional settings for the bearing, further explained below under Bearing setup

Sensors: configure proximity probes, key phasor/tacho position, and angle.

Runout compensation and reference orbit: input runout compensation or reference orbit data into the designated table or simply paste it from elsewhere.

Measurement: set shaft rotation direction, clearance circle size, and shape, number of periods, and averages taken into the average orbit calculation or manually input DC Gap.

Dewesoft orbit analyzer is compatible with most of the proximity probes on the market. In most cases you can use your existing installed proximity probes.

We suggest using Micro-Epsilon probes. Most of these probes can be connected directly to our data acquisition LV signal conditioning module without the need for a separate power supply. Probes cam bi powered directly from our signal amplifiers.

Can we integrate Bently Nevada proximity probes?

Yes. Depending on the customer’s system we can either connect to conditioned signal (3500) or directly to the proximitor using the power supply on the LV module.

Dewesoft orbit analysis solution offers a very attractive price compared to the other solutions available on the market. Not only the price of hardware and software is lower, but there are also no maintenance contract fees or any other hidden costs.

Our software licensing policy offers lifetime free software updates with new functionalities and bug fixes cost-free. And our global technical support is offered free of charge to all existing and new users.

Orbit analysis is a standard component for machine condition monitoring and can be combined with other capabilities of the Dewesoft Machine Condition Monitoring solution.

Temperature monitoring

Vibration monitoring

Strain monitoring

Pressure monitoring

Rotational speed monitoring

Force monitoring

Bearing faults

Overheating

Shaft un-balance

Detached mounting

Gear-tooth failure

Load misalignment

Stator excentricity

Other machine catastrophic failures

To save time, you can mount multiple sensors and measure and monitor several machine trains within the same setup in parallel. This is very useful when you want to monitor and analyze several machine trains at the same time.

The configuration is as simple as using a single instance. There can be any number of bearings defined within individual machine trains even when using more than a single instance of Orbit Analysis.

Dewesoft orbit analysis is a great investment in your future. Our solutions are constantly being improved, and new features are being added all the time. All updates to the modal testing software suite are free of charge.

Our industry-leading 7-year warranty on Dewesoft data acquisition systems means worry-free measurements for you. We are committed to ensuring that your investment in our measurement equipment was a good one - even when the unexpected occurs.

Together with world-class data acquisition technology, Dewesoft provides the best Modal testing and modal analysis solution your money can buy.

Brochures

Manual and Documentation

See and browse related and compatible data acquisition products.

Modular Data Acquisition (DAQ) System

Portable Data Acquisition (DAQ) Systems

Compact medium to high channel count data acquisition (DAQ) systems

Powerful Data Processing Computer and SSD Data Logger

Award-Winning Data Acquisition and Digital Signal Processing Software

Time-Series Database for Long-Term and Permanent Monitoring Applications

See and browse related and compatible testing solutions.

Vibration monitoring for gearboxes, fans, motors, pumps, etc.

Vibration and frequency analysis with a Fast Fourier transform

Noise and vibration analysis for rotating and reciprocating machinery

Measure angular vibration of the rotating shafts