Electric Motor Testing

As time progresses electric motors must fulfill higher and higher requirements concerning energy efficiency. Since 2011 all asynchronous motors must fulfill at least the level IE2 according to the IEC 60034 standard. Before this standard was established losses were considered at 0.5%. Now they must be determined. The efficiency and loss determination of motors require the highest accuracy of the whole measurement chain.

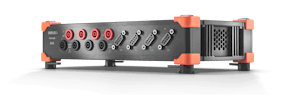

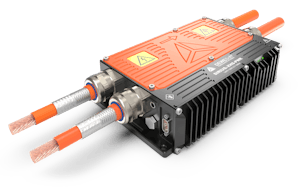

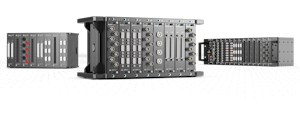

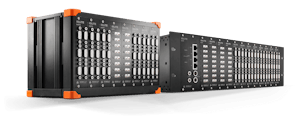

The Dewesoft power analyzer solution and the possibility of the additional software sensor calibration guarantee the highest accuracy for all measurement results. The modular hardware concept allows for the measurement of up to 12-phase motors as well as mechanical parameters such as speed, torque, and deformation. Additionally, parameters such as vibration, sound level, temperature, etc. can be measured fully synchronized to the power parameters. Power quality analysis (fundamental power, harmonics, THD, etc.) complements the analysis capabilities.