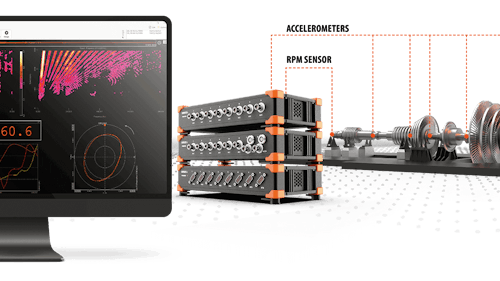

Distributed Hardware

Dewesoft offers the latest machine condition monitoring hardware.

The solution is designed for applications where distributed measurements of limitless numbers of perfectly synchronized vibration and temperature measurements are of the essence and where cost plays a significant role.

Robust and simple to configure devices ensure fast installation and low maintenance requirements. The solution is bringing the DAQ device very close to the sensor eliminating long analog cables and thus reducing noise pick-up and cost.

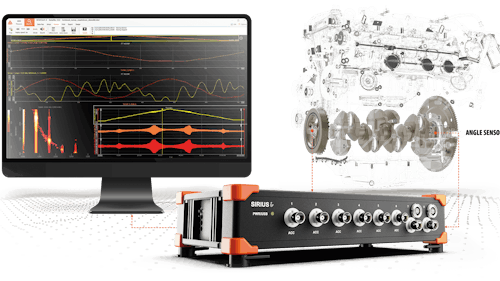

IOLITE Data Acquisition Systems

IOLITE X are our new generation of distributed DAQ devices for various condition monitoring sensors (vibration, voltage, etc.). They can be connected and distributed via standard TCP/IP network and offer PTP v2 synchronization. With ability to run math computations and store data directly on the device or send it via network to remote place, these units are perfect fit for majority of condition monitoring tasks. With up to 200 kHz sampling rate, IOLITE X units are also perfect for dynamix signal conditioning measurements where you need to sample data fast and perform critical calculation in real-time.

IOLITE EtherCAT is our family of measurement devices with single- or multi-channel general data acquisition with a wide range of input types with 24-bit resolution and 20 kS/s sampling speed. Several I/O modules are available for the measurement of voltage, current, strain gauge, vibration (IEPE and MEMS), temperature - universal thermocouple and RTD, digital I/O, and more. Devices can be easily daisy-chained with a single Ethernet cable with up to 50m node-to-node. EtherCAT communication ensures perfect synchronization between devices.

IOLITE rack units (R8, R8R, and R12) are designed for applications where a larger amount of channels is needed at the same spot while being part of a wider EtherCAT measurement network. All rack units feature a secondary EtherCAT bus that can be used for parallel real-time data output to a 3rd party control & protection system.

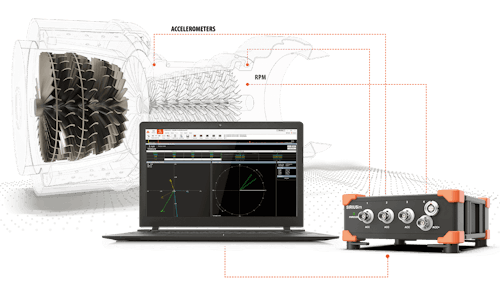

KRYPTON Rugged Data Acquisition Systems

KRYPTON DAQ devices feature single and multi-channel measurement devices in a rugged, waterproof, and high-temperature resistant package. These devices are perfect for use in harsh environments where conditions require high-shock proof and waterproof protection. Devices can be daisy-chained between each other using a single rugged cable with Lemo connectors for power, data, and synchronization. KRYPTON devices are meant to be used in the harshest environment while fitting into the same EtherCAT chain as IOLITE devices.