Innehållsförteckning

Bläddra bland kategorierna

Bläddra bland författare

AB

ABAlberto Boffi

AL

ALAlessia Longo

AH

AHAl Hoge

AB

ABAljaž Blažun

BJ

BJBernard Jerman

BČ

BČBojan Čontala

CF

CFCarsten Frederiksen

CS

CSCarsten Stjernfelt

DC

DCDaniel Colmenares

DF

DFDino Florjančič

EB

EBEmanuele Burgognoni

EK

EKEva Kalšek

FB

FBFranck Beranger

GR

GRGabriele Ribichini

Glacier Chen

GS

GSGrant Maloy Smith

HB

HBHelmut Behmüller

IB

IBIza Burnik

JO

JOJaka Ogorevc

JR

JRJake Rosenthal

JS

JSJernej Sirk

JM

JMJohn Miller

KM

KMKarla Yera Morales

KD

KDKayla Day

KS

KSKonrad Schweiger

Leslie Wang

LS

LSLoïc Siret

LJ

LJLuka Jerman

MB

MBMarco Behmer

MR

MRMarco Ribichini

ML

MLMatic Lebar

MS

MSMatjaž Strniša

ME

MEMatthew Engquist

ME

MEMichael Elmerick

NP

NPNicolas Phan

OM

OMOwen Maginity

PF

PFPatrick Fu

PR

PRPrimož Rome

RM

RMRok Mesar

RS

RSRupert Schwarz

SA

SASamuele Ardizio

SK

SKSimon Kodrič

SG

SGSøren Linnet Gjelstrup

TH

THThorsten Hartleb

TV

TVTirin Varghese

UK

UKUrban Kuhar

Valentino Pagliara

VS

VSVid Selič

WK

WKWill Kooiker

Ett nytt verktyg för att maximera effektiviteten hos hybrida och elektriska motorer

August 27, 2025

I takt med att utvecklingen mot hållbar och energieffektiv teknik intensifieras blir det alltmer avgörande att förstå de detaljerade aspekterna av elektromotorers verkningsgrad. Dewesofts Motoranalysmodul, integrerad med DewesoftX Power-modulen, ligger i framkant och gör det möjligt för ingenjörer att visualisera en motors elektriska och mekaniska effekt samt dess egenskaper på ett enhetligt sätt. Detta integrerade arbetssätt revolutionerar, när det kombineras med DewesoftX Power-modulen, hur elektriska effektparametrar beräknas och används i praktiken.

I den här artikeln kommer du att:

Förstå hur man beräknar en elektromotors verkningsgrad

Se hur en effektivitetsanalys utförs

Lära dig de viktigaste elementen i testning av elektromotorer

Motoranalys- och DewesoftX Power-modulerna kombinerar elektriska data med mätningar av mekaniskt vridmoment och rotation. Denna integration är sömlös, i skarp kontrast till användningen av separata effektanalysatorer och DAQ-instrument, som ofta leder till osynkroniserade och fragmenterade data. Dewesofts lösning erbjuder synkroniserade och integrerade data, vilket banar väg för en heltäckande förståelse av motorers verkningsgrad och förluster genom anpassningsbar 2D/3D-effektivitetskartering.

Vikten av elektrisk motoranalys

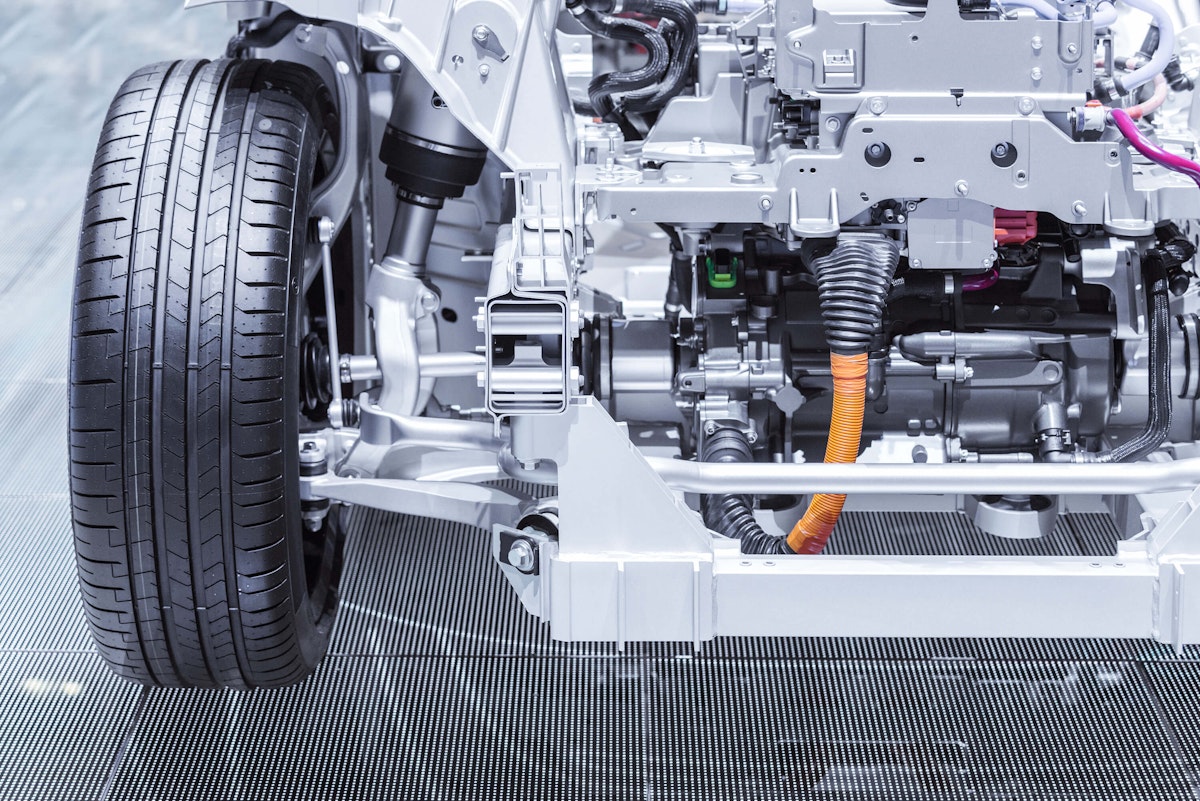

Elektrisk motoranalys är oumbärlig i dagens värld, särskilt för hybridfordon och elbilar. Motoranalysmodulen transformerar tidsdomänkomponenter av trefaseffekt till ortogonala stationära ramar (αβ) med hjälp av Clarke- och Park-transformationerna. Dessa transformationer konverterar AC-spänning och ström till DC, vilket förenklar verkningsgradsberäkningar och ger en tydligare fasutvärdering samt inspektion av den mekaniska rotationen.

Clarke-transformationen omvandlar tidsdomänens ABC-ram till en tvåkomponents αβ stationär ram, medan Park-transformationen omvandlar αβ-ramen till dq-referensramen. Denna kombination är avgörande för att analysera elektriska motorers verkningsgrad, särskilt i applikationer som involverar regenerativ bromsning och optimering av bränsleekonomi.

Tillsammans förenklar de verkningsgradsberäkningarna genom att effektivt omvandla AC-spänning och ström till DC. De är också ett bättre sätt att utvärdera fasen (Clarke) och inspektera spänning och ström i förhållande till den mekaniska rotationen (Park).

Strömlinjeformad systemkonfiguration

Motoranalysmodulen erbjuder en snabb och intuitiv konfigurering. Ingenjören väljer önskade mätningar och utgångar, och programvaran hanterar resten. Systemets användarvänliga gränssnitt säkerställer att all data är synlig under mätning och kan spelas upp i efterhand. Diagramregistreringsgrafer kan zoomas in/ut via markörer, vilket gör det möjligt för ingenjören att analysera data med valfri upplösning både på tids- och amplitudaxeln. Denna funktionalitet är avgörande för djupgående analyser och gör Dewesofts lösning idealisk för att förbättra verkningsgraden i hybridfordon och elbilar.

De grundläggande inställningarna för Clarke-/Park-transformationerna visas vid en statisk motorarbetspunkt. Verkningsgraden för frekvensomriktaren beräknas baserat på motor- och batterieffekt. En resolversensor används för att bestämma den mekaniska vinkeln och hastigheten.

Systemkonfigurationen i motorverkningsgradsmodulen är snabb och enkel. Ingenjören markerar helt enkelt rutorna för önskade mätningar och utgångar, och programvaran sköter resten.

All data är synliga under mätning och kan även spelas upp i efterhand. Diagramskrivarens grafer kan zoomas in/ut med hjälp av markörer för att visa data i valfri upplösning både på tids- och amplitudaxeln. Alla grafiska widget-typer är fritt konfigurerbara före, under och efter mätningen.

Avancerad signalbehandling för precisa mätningar

Noggrann signalbehandling är avgörande vid testning av elektrisk motorverkningsgrad. Dewesoft erbjuder hög bandbredd, hög noggrannhet och galvaniskt isolerade signalbehandlingsalternativ. Dessa inkluderar förstärkare för höga spännings- och strömsignaler samt kompatibilitet med ett brett urval av sensorer, såsom töjningsgivare, accelerometrar, termoelement och RTD-temperaturgivare. Denna flexibilitet är avgörande för datainsamlingsapplikationer (DAQ) inom olika industrisektorer.

Systemets kompatibilitet omfattar alla större typer av räknare, encoders, varvtalssensorer, momentsensorer och mer. Det kan använda alla typer av strömsensorer, från AC/DC-tänger till fluxgate-sensorer, vilket säkerställer en heltäckande datainsamling. Dessutom ökar möjligheten att ansluta andra sensorer och gränssnitt – såsom CAN BUS, CAN FD, IMU och GNSS-data samt hög- och lågupplösta videokameror – systemets mångsidighet.

Kombination av elektrisk effekt- och motoranalys

Att kombinera elektrisk effektanalys med mekanisk motoranalys erbjuder många fördelar. Genom att förstå en motors verkningsgradskarta kan operatörer säkerställa optimal prestanda och lång livslängd. Denna integration möjliggör observation av motordrift i alla fyra kvadranter, med kvantifiering av prestanda i både motor- och generatordrift samt i framåt- och bakåtriktad rotation. Denna kapabilitet är avgörande för applikationer som eftersträvar högre effektivitet, exempelvis hybridfordon och elbilar.

Analys av parametrar som torque ripple kan avslöja potentiella mekaniska problem och möjliggöra förebyggande underhåll innan haveri uppstår. Tidig upptäckt av avvikelser ökar säkerheten och förhindrar riskfyllda driftförhållanden. En detaljerad prestandaanalys hjälper ingenjörer att optimera styralgoritmer, förbättra driften samt jämföra olika motorkonstruktioner för att välja den mest lämpliga lösningen för applikationen.

Nyckelfunktioner i motoranalyssystemet

Motoranalyssystemet är utrustat med flera centrala funktioner som förstärker dess prestanda:

Clarke- och Park- transformationer: Dessa matematiska transformationer förenklar verkningsgradsberäkningar genom att omvandla AC-spänning och -ström till DC. Detta är avgörande för att utvärdera motorns effekt i realtid, beräknad från mekaniska sensorer på axeln.

Kompatibilitet med alla räknare/varvtals-/encoder-sensorer: Den integrerade räknarmodulen gör det möjligt att övervaka motorns prestanda under olika driftförhållanden och identifiera områden med maximal verkningsgrad.

Hantering av alla typer av signaler och sensorer: Systemet kan hantera högspännings- och högeffektsignaler samt förstärkare för töjning, tryck, moment, temperatur, förskjutning och mer.

Digitala in- och utgångar samt bussdata: Stöd för analoga källor, digitala utgångar och bussdata från olika gränssnitt säkerställer synkroniserad datainsamling.

Effektivitetskartering: Ingenjörer kan visualisera motorns prestanda under olika driftförhållanden och identifiera optimala punkter för energibesparing och förlängd livslängd.

Flersfasanalys: Systemet kan analysera motorer i enfas, tvåfas, trefas och fler, vilket säkerställer en heltäckande bedömning och harmonisk drift.

Hög samplingshastighet: Datainsamling med snabba intervaller ger högupplösta insikter i motorbeteende och möjliggör detektering av transienta händelser och anomalier.

Omriktartestning: Utvärdering av prestanda och verkningsgrad hos omriktare säkerställer en ren och stabil strömförsörjning samtidigt som motorns verkningsgradskurva optimeras.

Kraftfull rapportgenerering: DewesoftX-mjukvaran möjliggör skapandet av höggradigt grafiska rapporter direkt efter mätning, vilket underlättar tolkning av data.

Idealisk DAQ-hårdvara för verkningsgradstestning av motorer

För de högsta bandbredderna är Dewesofts SIRIUS XHS DAQ-instrument det idealiska valet. Denna kompakta och robusta modul erbjuder 16-bitars SAR-ADC:er med samplingshastighet upp till 15 MS/s per kanal. För applikationer som kräver hög dynamik kan den konfigureras som en 24-bitars ADC med delta-sigma-prestanda på upp till 2 MS/s per kanal. SIRIUS XHS-modulen ansluts via USB 3.0 till valfri Windows-dator med mjukvaran installerad, vilket gör den till ett mångsidigt verktyg för en rad olika testscenarier.

För mindre krävande applikationer erbjuder SIRIUS DualCore®-instrument 200 kS/s samplingshastighet, 24-bitars upplösning och över 150 dB dynamiskt omfång. Dessa instrument är särskilt lämpliga för industri- och konsumentelektronikapplikationer och levererar tillförlitlig och noggrann datainsamling.

Läs mer om SIRIUS XHS:

För mindre krävande applikationer inom industriella och konsumentelektroniska tillämpningar kan SIRIUS DualCore®-instrument användas. De erbjuder 200 kS/s samplingshastighet, 24-bitars upplösning och ett dynamikområde på över 150 dB, vilket säkerställer tillförlitlig och noggrann datainsamling i ett brett spektrum av användningsområden.

Läs mer om SIRIUS DualCore:

Testning av förbränningsmotorer

Trots dagens fokus på elektriska motorer måste vi komma ihåg att hybridfordon även innehåller en förbränningsmotor. Förbränningsanalysatorn i DewesoftX-programvaran kan testa bensin-, etanol-, diesel-, vätgas- och andra motortyper. Systemet används för FoU, motoroptimering samt testning av tändsystem, avgassystem och ventilmekanismer.

Samma SIRIUS datainsamlingshårdvara (DAQ) kan användas för att ansluta tryck- och andra sensorer på motorn. Varje SIRIUS-modul erbjuder åtta analoga ingångar för alla större sensortyper: laddning, IEPE, spänning, töjning, vridmoment, temperatur och fler. Dessutom kan alla standard varvtalssensorer användas, exempelvis i bil (t.ex. 60-2 kuggtand), encoder, CDM+Trg, osv. En fullt synkroniserad CAN- eller CAN FD-port finns tillgänglig för direkt och synkroniserad höghastighets-CAN-datainsamling. DewesoftX-programvaran erbjuder dessutom stöd för OBDII, J1939 och CAN DBC-filer för enkel kanalkonfiguration.

Dewesofts förbränningsanalysatorer skickar analysresultat till testbäddar via AK-protokollet eller till ETAS INCA och liknande system via CAN.

Tillämpningar bortom motoreffektivitetstestning

Avancerad motoranalys sträcker sig långt bortom testning av elektrisk motoreffektivitet. Den är avgörande inom flera områden, inklusive industriella maskiner, flyg- och rymdindustrin, marina tillämpningar, forskning samt hushållsapparater. Optimering av effektivitet är ett gemensamt mål inom alla dessa applikationer.

Några ytterligare användningsområden:

Bestämning av optimala driftparametrar: Fastställande av ideala driftsförhållanden för att maximera prestanda och effektivitet.

Långtidstestning av motorprestanda: Övervakning och analys över tid för att identifiera trender och potentiella problem.

Felsökning och prediktion: Tidig upptäckt av fel för att förhindra haverier och minimera stillestånd.

Elektrisk och mekanisk inriktning: Säkerställande av att elektriska och mekaniska komponenter arbetar i harmoni.

Optimering av växelriktarinställningar: Finjustering för att förbättra motorprestanda och effektivitet.

Vridmomentsrippleanalys: Identifiering och åtgärdande av momentripple för att förebygga mekaniska problem och förbättra driften.

Förbättring av styralgoritmer: Anpassning av algoritmer för att optimera motorstyrning och effektivitet.

Visualisering av fyrkvadrantsdrift: Analys av motorprestanda i alla driftslägen för en heltäckande bedömning.

Inställning och optimering av växelriktarstyrning: Finjustering för att maximera effektivitet och prestanda.

Slutsats

De snabba framstegen inom el- och hybridfordonsteknik kräver snabbare och mer exakt motoranalys. Dewesofts Motor Analysis-programvara, i kombination med DewesoftX Power-modulen, erbjuder en optimal lösning för ingenjörer som vill optimera motorprestanda och effektivitet.

Detta integrerade tillvägagångssätt säkerställer en heltäckande datainsamling och analys, vilket stärker utvecklingen och förfiningen av elektriska motorer och kraftelektronik.

Oavsett om det gäller hybridfordon, industriella maskiner eller konsumentelektronik, är förmågan att mäta och förbättra effektivitet avgörande. Med Dewesofts verktyg kan ingenjörer uppnå högre verkningsgrad, lägre bränsleförbrukning och minskat koldioxidavtryck i sina applikationer.

Med funktioner som effektivitets- och förlustkartläggning, analys av regenerativ bromsning samt detaljerade rapporteringsmöjligheter, ser Dewesoft till att ingenjörer har de verktyg som krävs för att driva innovation och hållbarhet inom motoreffektivitetstestning.